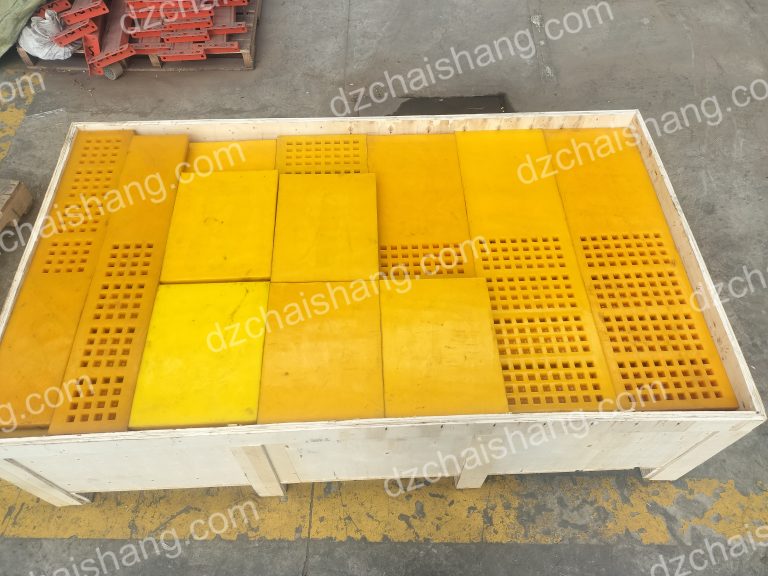

غربال الشاشة المشدود، غربال البولي يوريثين، غربال الشاشة PU

استكشاف مزايا غربال الشاشة المشدود في التطبيقات الصناعية

فهم متانة وكفاءة غربال شاشة البولي يوريثين (PU)

يوفر غربال الشاشة PU أيضًا نقل اهتزاز فائق، مما يعزز أداء الغربلة. يمكن لمادة البولي يوريثان أن تنقل الاهتزاز بشكل فعال، مما يسمح بعملية غربلة أكثر شمولاً وكفاءة. هذه الميزة مفيدة بشكل خاص في الصناعات التي تتطلب عمليات غربلة ذات قدرة عالية.

علاوة على ذلك، فإن غربال الغربلة PU خفيف الوزن مقارنة بالمناخل المعدنية أو المطاطية. هذه الخفة تجعل من السهل التركيب والتعامل معها، مما يقلل الوقت والجهد اللازمين لتركيب الغربال وصيانته. على الرغم من خفته، فإن غربال الشاشة PU لا يتنازل عن القوة أو المتانة، مما يجعله خيارًا عمليًا لمختلف التطبيقات الصناعية.

في الختام، يوفر غربال الشاشة PU، بتصميمه المشدود للشاشة، مزيجًا من المتانة والكفاءة من الصعب أن تتطابق. إن مقاومته للتآكل، والقدرة على الحفاظ على الشكل تحت الضغط، والمرونة الممتازة، ونقل الاهتزاز الفائق، وطبيعته خفيفة الوزن تجعله خيارًا مثاليًا للصناعات التي تتطلب عمليات الغربلة الشاقة. ومن خلال فهم هذه الخصائص، يمكن للشركات اتخاذ قرارات مستنيرة عند اختيار الغربال المناسب لاحتياجاتها، مما يضمن الأداء الأمثل والفعالية من حيث التكلفة.

Understanding the durability and efficiency of a polyurethane (PU) screen SIEVE is crucial in various industries, particularly in mining, quarrying, and aggregate processing. These sieves are essential tools that play a significant role in separating, sizing, and sorting different materials. The pu screen sieve, also known as a tensioned screen sieve, has gained popularity due to its superior properties compared to traditional metal or rubber sieves.

Firstly, the durability of the PU screen sieve is one of its most notable features. Polyurethane is a robust material known for its exceptional resistance to wear and tear. It can withstand harsh conditions, including exposure to abrasive materials, high temperatures, and corrosive chemicals. This resilience makes it an ideal choice for industries that require heavy-duty sieving operations. Moreover, the longevity of PU screen sieves reduces the need for frequent replacements, leading to significant cost savings in the long run.

The design of the PU screen sieve also contributes to its durability. The tensioned screen design ensures that the sieve maintains its shape and integrity even under intense pressure. This design feature prevents sagging and deformation, which are common issues with other types of sieves. The tensioned screen design also allows for more efficient sieving as it keeps the sieve’s surface flat and taut, ensuring consistent and accurate results.

In addition to its durability, the PU screen sieve is also known for its efficiency. The polyurethane material offers excellent elasticity, which helps to reduce blinding and pegging. Blinding occurs when particles become lodged in the sieve’s openings, reducing its effectiveness. Pegging happens when particles get stuck in the sieve’s apertures, preventing other particles from passing through. The elasticity of the polyurethane material allows the sieve to flex and dislodge any trapped particles, thereby maintaining its sieving efficiency.

The PU screen sieve also offers superior vibration transmission, which enhances its sieving performance. The polyurethane material can effectively transmit vibration, allowing for more thorough and efficient sieving. This feature is particularly beneficial in industries that require high-capacity sieving operations.

Furthermore, the PU screen sieve is lightweight compared to metal or rubber sieves. This lightness makes it easier to install and handle, reducing the time and effort required for sieve installation and maintenance. Despite its lightness, the PU screen sieve does not compromise on strength or durability, making it a practical choice for various industrial applications.

In conclusion, the PU screen sieve, with its tensioned screen design, offers a combination of durability and efficiency that is hard to match. Its resistance to wear and tear, ability to maintain shape under pressure, excellent elasticity, superior vibration transmission, and lightweight nature make it an ideal choice for industries requiring heavy-duty sieving operations. By understanding these properties, businesses can make informed decisions when choosing the right sieve for their needs, ensuring optimal performance and cost-effectiveness.