Tấm trommel Polyurethanesieve Trung Quốc, tấm trommel PU của nhà máy

دور لوحة طبلة PU الهزة فيالمصنعفيعمليات التصنيعالحديثة

دور لوحة طبلة PU الهزازة فيالمصنعفيعمليات التصنيعالحديثة

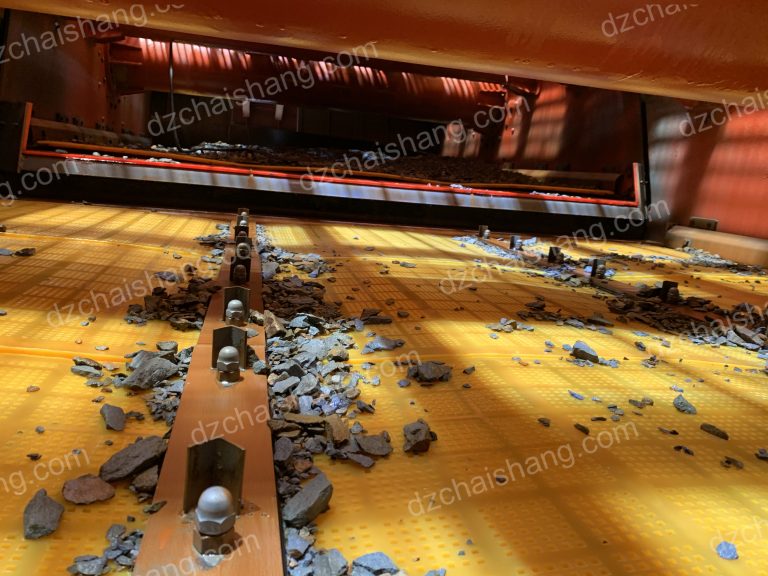

إندورلوحةطبلة ปู الهزازةفيالمصنعفي عمليات التصنيع الحديةهوموضوعذو أهميةكبيرة،خاصةفي سياقالصناعة التحويليةالصينية。 يعد هذا المكون، الذي غالبًا ما يكون مصنوعًا من مادة البولي يوريثين (PU)،جزءًامهمًامنآلة الغربلة،وهيآلة أسطوانيةكبيرةتستخدم لفرزالموادوفصلها。 لوحةالغربال، المعروفةأيضًاباسم الغربال،هيجزءمن الآلة التي تقوم بالفرز الفعلي。 وهي مصممةبفتحات بأحجاممختلفةللسماح للمواد المختلفة بالمرورمنخلالها، وبالتالي تحقيق الفصل المطلوب。

يعد استخداممادة البولي يوريثينفي صناعةألواحغربلة الطبولخيارًا استراتيجيا。 البولي يوريثينمادة متعددةالاستخدامات معروفةبمتانتها ومرونتهاومقاومتها للتآكلوالتأثيرات。 هذهالخصائصتجعلها مادةمثاليةلألواح الطبول، التي تتعرض للتآكلالمستمرأثناء عمليةالفرز。 علاوةعلىذلك،تتميز صفائحغربالغربال البولي يوريثانبخفة الوزن، مما يقلل من الوزنالإجماليلآلة غربالالحديدويجعل تشغيلهاوصيانتها أسهل。

فيالصناعة التحويليةالصينية، ينتشراستخدامصفائح غربالغربالالبولي يوريثينعلىنطاقواسع。 ويرجع ذلك إلى حد كبير إلىوفرةإمدادات البلاد من المواد الخام وقدرات التصنيع المتقدمة。 لقدأتقنالمصنعون الصينيونفنإنتاج ألواحغربالالبولي يوريثينعاليةالجودة التي تلبي المعايير الصارمةلعمليات التصنيعالحديثة。 يتماستخدامهذه الألواح في مجموعة متنوعةمنالصناعات، بمافيذلكالتعدين والبناءوإدارة النفايات،علىسبيل المثاللاالحصر。

يعد هزازالمصنعمكونًا مهمًاآخرفيآلةغربلة الحجارة。 وهومسؤولعنإنشاء الاهتزازات التي تحرك الموادعبرل وحةالطبلة。 ويمكنتعديلشدةوتكرار هذهالاهتزازات لتتناسبمعالمتطلبات المحددةلعمليةالفرز。 على سبيل المثال، قد تتطلبالموادالأثقل اهتزازاتأقوى لتحريكها، بينمايمكن فرزالموادالأخف باهتزازاتأقلشدة。 إنالقدرةعلىالتحكمفي هذهالمعلماتتجعلهزاز المصنع أداة لا غنى عنها فيعملياتالتصنيع الحديثة。

فيالصين،يعد إنتاج هزازات المصنع صناعةمتخصصة。 طورت الشركات المصنعة الصينيةمجموعةمن التصاميموالتقنيات المبتكرةلتعزيزأداء وكفاءةهذهالأجهزة。 علىسبيلالمثال،تم تجهيزبعضهزازات المصانعبأنظمةتحكم متقدمة تسمح بضبط معلمات الاهتزازبدقة。 تم تصميم البعض الآخر بميزات موفرةللطاقة لتقليلتأثيرهاعلى البيئة。

في الختام، فإن لوحة طبلة PUالهزازةفيالمصنع تلعبدورًامحوريًافي عمليات التصنيع الحدية。 تعتبروظيفتهاكأداة فرزوفصلأمرًابالغ الأهميةلكفاءة وإنتاجيةالعديدمن الصناعات。 إن استخدام مادة البولي يوريثينفيتصنيعألواح غربلةالطبول،إلىجانب التصميموالتكنولوجيا المتقدمينلهزازات المصانعالصينية،قد أدى إلى تحسين أداء وموثوقيةهذهالمكونات بشكلكبير。 معاستمرارالصناعة التحويليةالصينيةفي التطوروالابتكار، يمكنناأننتوقعرؤية المزيد من التقدم في هذا المجال، مما يساهم في التحسينالمستمر لعمليات التصنيعفي جميعأنحاءالعالم。

في الختام، فإن لوحة طبلة PUالهزازةفيالمصنع تلعبدورًامحوريًافي عمليات التصنيع الحدية。 تعتبروظيفتهاكأداة فرزوفصلأمرًابالغ الأهميةلكفاءة وإنتاجيةالعديدمن الصناعات。 إن استخدام مادة البولي يوريثينفيتصنيعألواح غربلةالطبول،إلىجانب التصميموالتكنولوجيا المتقدمينلهزازات المصانعالصينية،قد أدى إلى تحسين أداء وموثوقيةهذهالمكونات بشكلكبير。 معاستمرارالصناعة التحويليةالصينيةفي التطوروالابتكار، يمكنناأننتوقعرؤية المزيد من التقدم في هذا المجال، مما يساهم في التحسينالمستمر لعمليات التصنيعفي جميعأنحاءالعالم。