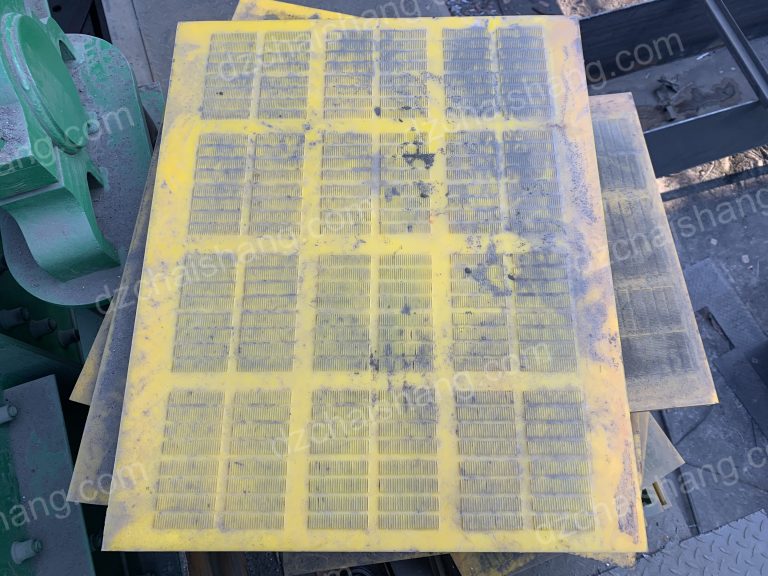

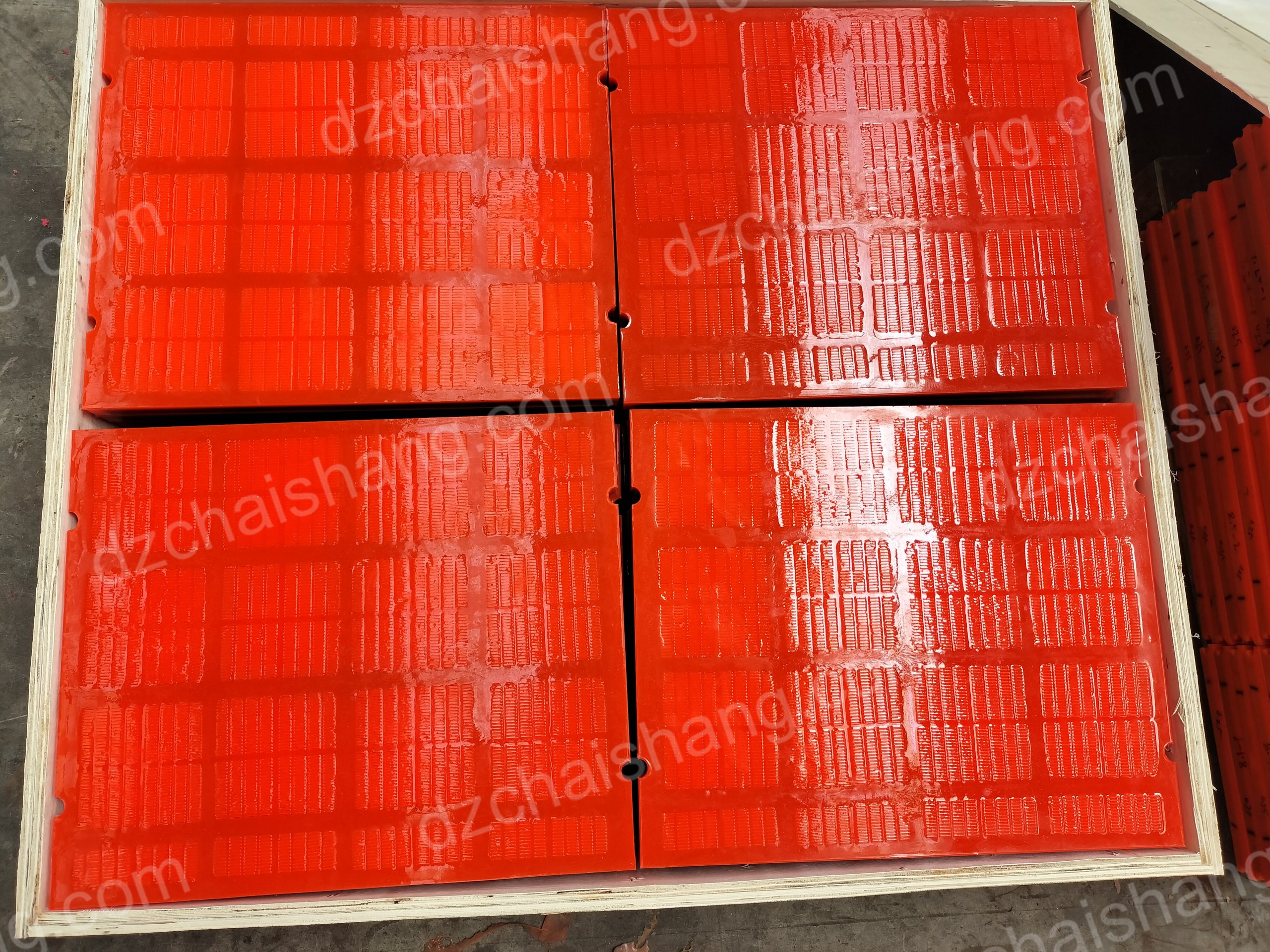

tấm sàng polyurethane,màn hình polyurethane,nhà máy sản xuất lưới sàng rung

= .. لوح==u0629الغربل ةمنالقالب。 .. .. ي… === ~ الاهتزازية。 ..” ” اللازمةلعملية الغربلة。 يتم ربط الشبكة بلوح==u0629 البول يوريbين .. آمنًاودائمًا。

а = ================================================== ==== ========== – – ينالمكتملة تعبئتها تدةً .. أناءالنقل。 بمجردوصولهاإلى .. .. في آلات الغربلة ” .. علومالمواد ” ” ” والفهمالعميقلخصئئ البولييوريثينج .. منتج قادر على تح=u0645ل الظروفالقاسية غربلةموثوقةوفعا

ف อี u064a .. .. .. الجودةالشاملة والأداءللمنتج النهائي。 بدءً امناختيارما) البولي يوريينلي..” ضمانتلبيةالألو= للمعاييرالعاليةɊؤa .. متينومرنوعالي الكفاءةيُستخدمعI نطاقواسعفيآلات =ولالعالم。

br

br