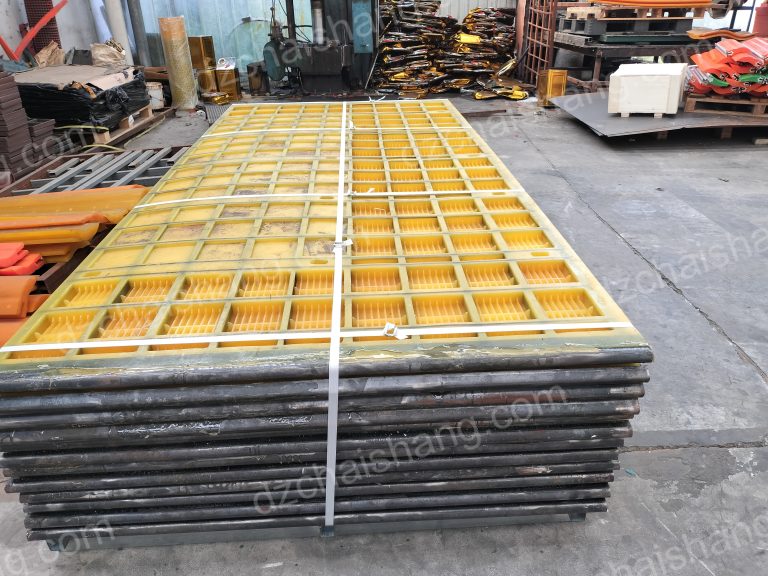

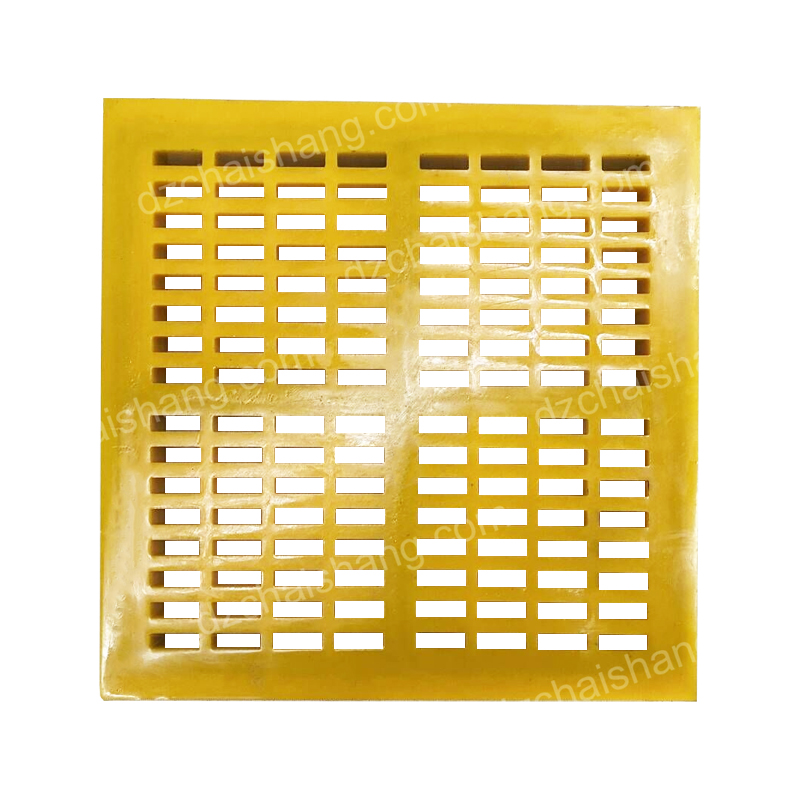

Lưới màn hình cao su rung, tấm màn hình cao su

فوائد استخدام شبكة شاشة المطاط الاهتزاز في التطبيقات الصناعية

شبكة الشاشة المطاطية الاهتزازية ، والمعروفة أيضًا باسم لوحة شاشة المطاط ، هي مادة متعددة الاستخدامات ودائمة تستخدم عادة في التطبيقات الصناعية. يتكون هذا النوع من شبكة الشاشة من مطاط عالي الجودة يقاوم البلى ، مما يجعله مثاليًا للاستخدام في البيئات الصعبة. هناك العديد من الفوائد لاستخدام شبكة شاشة المطاط الاهتزازية في التطبيقات الصناعية ، بما في ذلك قدرتها على الفحص والمواد المنفصلة بفعالية ، وعمرها الطويل ، وسهولة التثبيت والصيانة. المواد المطاطية مرنة ويمكن تشكيلها بسهولة في أشكال وأحجام مختلفة ، مما يسمح بفحص دقيق للمواد ذات الأحجام المختلفة. هذا يجعلها خيارًا مثاليًا للصناعات التي تتطلب فصلًا دقيقًا للمواد ، مثل التعدين والبناء وإعادة التدوير. يساعد الإجراء الاهتزازي لشبكة الشاشة على فصل المواد بشكل فعال بناءً على الحجم ، مما يضمن أن الجزيئات المطلوبة فقط تمر أثناء الاحتفاظ بالجزيئات الأكبر لمزيد من المعالجة. المواد المطاطية متينة للغاية ومقاومة للتآكل ، مما يجعلها خيارًا فعالًا من حيث التكلفة للتطبيقات الصناعية. على عكس شبكة الشاشة المعدنية التقليدية ، فإن شبكة الشاشة المطاطية أقل عرضة لارتداء المسيل للدموع ، مما يؤدي إلى انخفاض تكاليف الصيانة وعمر الخدمة الأطول. هذه المتانة تجعل شبكة شاشة المطاط تهتز اختيارًا موثوقًا للصناعات التي تتطلب عمليات فحص مستمرة ، مثل محطات المعالجة الإجمالية ومرافق معالجة المواد السائبة.

فائدة أخرى من استخدام شبكة شاشة المطاط الاهتزاز هي سهولة التثبيت والصيانة. تتيح الطبيعة المرنة للمواد المطاطية التثبيت السريع والسهل على معدات الفحص الحالية ، مما يقلل من وقت التوقف وزيادة الإنتاجية. بالإضافة إلى ذلك ، تتطلب شبكة شاشة المطاط الحد الأدنى من الصيانة مقارنة بشاشة الشاشة المعدنية ، لأنها لا تصدأ أو تتآكل بمرور الوقت. هذا يعني أن الصناعات يمكن أن توفر الوقت والمال على تكاليف الصيانة ، مما يتيح تشغيل أكثر كفاءة لمعدات الفحص الخاصة بهم. يمكن أن تستفيد الصناعات التي تتطلب فحصًا دقيقًا للمواد ، مثل التعدين والبناء وإعادة التدوير ، من متانة ومرونة شبكة شاشة المطاط. من خلال اختيار شبكة شاشة المطاط الاهتزاز لاحتياجات الفحص الخاصة بهم ، يمكن للصناعات تحسين الكفاءة ، وتقليل تكاليف الصيانة ، وزيادة الإنتاجية الإجمالية.

كيفية الحفاظ بشكل صحيح على لوحات شاشة المطاط وتنظيفها لعمر طويل

لوحات شاشة المطاط هي مكون أساسي في عملية الفحص لمختلف الصناعات مثل التعدين والتجميع وإعادة التدوير. تم تصميم لوحات شاشة المطاط هذه لتحمل الظروف القاسية لعمليات الفحص ، مما يوفر فحصًا فعالًا وفعالًا للمواد. ومع ذلك ، مثل أي معدات أخرى ، تتطلب لوحات شاشة المطاط الصيانة والتنظيف المناسبين لضمان طول العمر والأداء الأمثل. يمكن أن يقلل هذا التراكم من كفاءة فحص اللوحات ، مما يؤدي إلى انخفاض الإنتاجية وزيادة وقت التوقف. لمنع هذا التراكم ، من المهم تنظيف لوحات شاشة المطاط بانتظام.

هناك العديد من الطرق التي يمكن استخدامها لتنظيف لوحات شاشة المطاط ، اعتمادًا على نوع المواد التي تراكمت على السطح. تتمثل إحدى الطرق الشائعة في استخدام رذاذ الماء عالي الضغط لإزالة المادة من الشاشة. هذه الطريقة فعالة لإزالة المواد السائبة مثل الأوساخ والغبار والجزيئات الصغيرة. ومع ذلك ، بالنسبة لمزيد من المواد العنيدة مثل الطين أو المواد اللاصقة ، قد تكون هناك حاجة إلى فرشاة أو مكشطة لإزالة التراكم يدويًا. بمرور الوقت ، يمكن أن تلبس أو ممزقة المواد المطاطية لألواح الشاشة ، مما يؤدي إلى انخفاض كفاءة الفحص والفشل المحتمل للوحات. يمكن أن يساعد الفحص المنتظم للألواح في تحديد أي مشكلات في وقت مبكر ومنع الإصلاحات أو البدائل المكلفة.

لتمديد عمر لوحات شاشة المطاط ، من المهم اتباع جدول الصيانة العادي. يجب أن يتضمن هذا الجدول تنظيف اللوحات بعد كل عملية فحص ، وفحص لوحات التآكل والأضرار ، واستبدال أي لوحات متآكلة أو تالفة حسب الحاجة. باتباع جدول الصيانة ، يمكنك التأكد من أن لوحات شاشة المطاط الخاصة بك تستمر في أداء أفضل ما لديها وتوفير فحص فعال للمواد. يعد التوتر الصحيح لألواح الشاشة ضروريًا لتحقيق كفاءة الفحص الأمثل ومنع التآكل المبكرة للألواح. بمرور الوقت ، يمكن أن يصبح توتر لوحات الشاشة فضفاضًا ، مما يؤدي إلى تراجع أو اختلال اللوحات. لمنع ذلك ، من المهم التحقق بانتظام من توتر شاشة الشاشة والضبط حسب الحاجة. باتباع جدول الصيانة العادي ، وفحص لوحات التآكل والأضرار ، والتوتر بشكل صحيح على اللوحات على سطح السفينة ، يمكنك التأكد من استمرار لوحات شاشة المطاط في توفير فحص فعال للمواد لسنوات قادمة. تذكر أن لوحة شاشة المطاط التي تم صيانتها جيدًا هي مفتاح عملية فحص ناجحة.