中国橡胶筛网,橡胶筛网厂

استكشافعمليةالإنتاج في مصانع شبكات الغربلة المطاطيةفيالصين

تشتهرمصانعالشبكات المطاطيةفيالصين بمنتجاتهاعالية الجودة، والتي تستخدم فيمجموعةمتنوعةمن الصناعات في جميع أنحاء العالم。 لقد أتقنت هذه المصانع فن إنتاج شبكات مطاطية متينةومرنةومرنة يمكنهاتحملالظروف القاسيةوالاستخدام المكثف。 تعد عملية الإنتاج في هذهالمصانعمزيجًا رائعًامنالحرفية التقليدية والتكنولوجيا الحديثة، مما ينتج عنه منتجات عملية وموثوقة。

تبدأعملية الإنتاج باختيار الموادالخام。 تنتج المصانعمطاطًا عالي الجودة، وهو المادةالأساسية المستخدمةفيإنتاج شبكةالغربلة。 يتم اختيار المطاط بعنايةللتأكدمنأنه يتمتعبالخصائص المناسبةللمتانة والمرونةومقاومة التآكل。 تعد جودة المطاط أمرًا بالغ الأهميةلأنها تؤثربشكلمباشرعلى أداء المنتج النهائي وطولعمره。

بمجرداختيار المطاط، تتم معالجته بعد ذلك إلى شكل يمكن استخدامهلإنشاءشبكة الشاشة。 يتضمنذلكسلسلةمن الخطوات بما في ذلك التنظيفوالتجفيفوطحن المطاطإلىمسحوقناعم。 يتم بعد ذلك خلط مسحوق المطاطمعموادأخرى لتكوينمركبلهالخصائص المطلوبة。 يتم بعد ذلك تسخين هذا المركبوبثقهمنخلال قالبلتشكيلورقةمن المطاط.

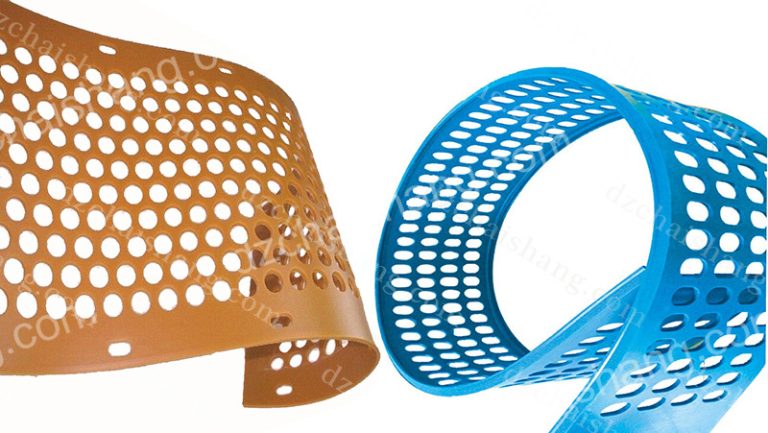

الخطوةالتالية في عملية الإنتاج هي إنشاءنمطالشبكة。 ويتمذلكباستخدامآلة متخصصةتقطعالألواح المطاطيةإلىنمطشبكي。 تستخدمالآلةسلسلةمن الشفرات لقطع المطاط، مما يؤدي إلى إنشاء شبكة منالثقوبالتيتشكل الشبكة。 يمكن تعديل حجم وشكل الثقوبلإنشاءأنواع مختلفة منالشبكات، اعتمادًاعلى المتطلبات المحددة للعميل.

بعدإنشاءنمط الشبكة، يتم بعد ذلك إخضاعالصفيحة المطاطيةلعملية معالجة。 يتضمنذلكتسخينالمطاط إلىدرجةحرارةعالية، ممايجعلهيتصلبويصبح أكثرمتانة。 تساعدعمليةالمعالجة أيضًاعلىتحسينمقاومة المطاطللتآكل،مما يجعلهأكثرملاءمة لتطبيقاتالخدمة الشاقة.

بمجرداكتمال عمليةالمعالجة،يتم بعد ذلك فحص شبكة الشاشة المطاطيةللتأكدمن الجودة。 يتضمنذلكفحصالشبكة بحثًاعنأيعيوبأو تناقضات،والتأكدمن مطابقتهاللمواصفات المطلوبة。 يتم رفض أي شبكة لا تستوفي معاييرالجودة ويتمإعادتهالإعادة المعالجة。

وأخيرًا،يتم تعبئةشبكةالغربلة المطاطيةوإعدادها للشحن。 تهتمالمصانعكثيرًا بتغليفالشبكةلضمان حمايتهاأثناءالنقل ووصولهاإلىوجهتهافي حالةممتازة。 يتم بعد ذلك شحن الشبكة المعبأةإلىالعملاءفي جميعأنحاءالعالم، وتكونجاهزةللاستخدام فيمجموعةمتنوعةمن التطبيقات。

في الختام، تعد عملية الإنتاج في مصانع الشبكات المطاطيةفي الصينعمليةمعقدة ودقيقة، وتتضمنسلسلة منالخطواتمناختيار الموادالخامللفحص النهائي للمنتج النهائي。 يتجلىالتزامالمصانع بالجودةوالاهتمام بالتفاصيلفيالأداء الفائقوالمتانة لمنتجاتهاالشبكية المطاطية。 وهذا، بالإضافةإلى قدرتهاعلىتخصيص الشبكةلتلبيةمتطلبات العملاءالمحددة، يجعلهاالخيارالمفضل للصناعات في جميع أنحاء العالم。

تأثيرصناعةشبكة الشاشةالمطاطيةفي الصينعلىالسوق العالمية

في الختام، كان لصناعة شبكات الشاشةالمطاطية في الصين تأثير عميق على السوقالعالمية。 وقد مكنتها قدرتها على إنتاج منتجات عالية الجودةبأسعار تنافسية،إلىجانب قدراتهاالتصنيعية المتقدمةوموقعها الاستراتيجي،منتلبية الطلبالعالمي المتزايدعلىشبكة الشاشةالمطاطية。 ومع ذلك، مع استمرار نمو الصناعة، ستحتاج إلى مواجهةتحديات الاستدامةالبيئيةمن أجلضماناستمراريتها علىالمدىالطويل.

然而,中国橡胶筛网行业的增长也引发了人们对环境可持续性的担忧。橡胶筛网的生产涉及使用天然橡胶,而天然橡胶的资源日益稀缺。这导致人们呼吁该行业采取更可持续的做法,例如使用再生橡胶和开发合成替代品。