Double boong Modular Mescel Mesh Mesh cho màn hình rung

فوائد استخدام شاشة البولي يوريثان المعيارية مزدوجة سطح السفينة

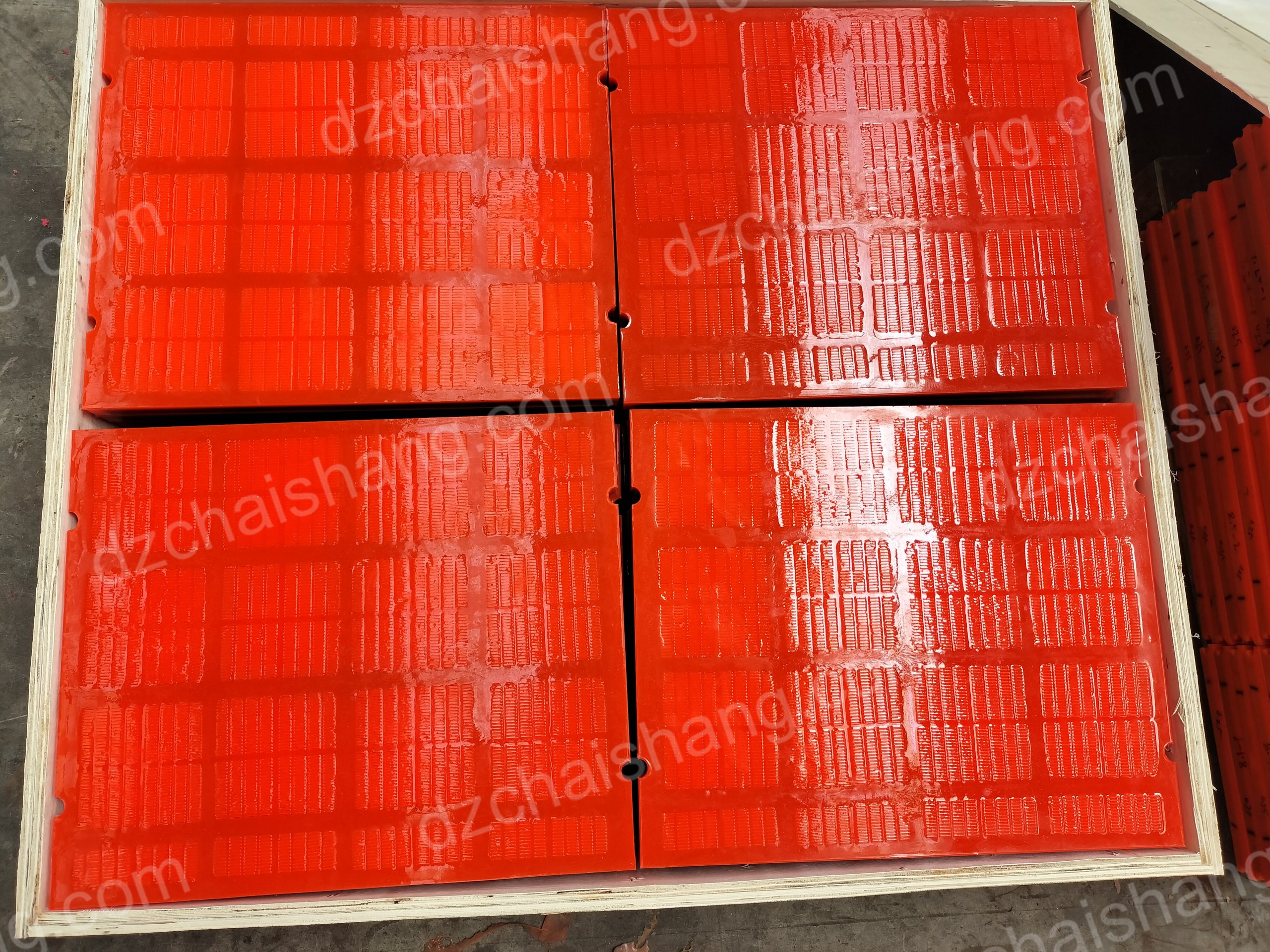

شبكة شاشة البولي يوريثان المزدوجة على سطح السفينة هي خيار شائع للشاشات الاهتزازية في مختلف الصناعات بسبب فوائدها العديدة. يتكون هذا النوع من شبكة الشاشة من مادة البولي يوريثان عالية الجودة ، والتي توفر متانة وأداء استثنائيين. في هذه المقالة ، سوف نستكشف فوائد استخدام شبكة شاشة البولي يوريثان المعيارية المزدوجة لشاشات الاهتزاز. البولي يوريثان هو مادة متينة للغاية يمكنها تحمل الظروف القاسية للشاشات الاهتزازية ، مثل التأثير العالي والتآكل. هذا يعني أن شبكة الشاشة ستستمر لفترة أطول وتتطلب استبدالًا أقل تكرارًا ، وتوفير الوقت والمال على المدى الطويل. يسمح التصميم المعياري لشبكة الشاشة بسهولة التثبيت والإزالة ، مما يجعل من السهل استبدال الألواح البالية أو تخصيص الشاشة لتلبية متطلبات الفحص المحددة. تضمن هذه المرونة أن تعمل شاشة الاهتزاز بكفاءة مثالية ، مما يؤدي إلى زيادة الإنتاجية وتقليل وقت التوقف.

ميزة أخرى من شبكة شاشة البولي يوريثان المعيارية مزدوجة سطح السفينة هي قدرتها على تقليل مستويات الضوضاء. تمتص مادة البولي يوريثان الاهتزازات وتثبت الصوت ، مما يخلق بيئة عمل أكثر هدوءًا للمشغلين. هذا مهم بشكل خاص في الصناعات التي يكون تلوث الضوضاء مصدر قلق ، مثل مواقع التعدين أو البناء. هذا يجعلها مثالية للاستخدام في التطبيقات التي قد تتلامس فيها الشاشة بالمواد أو المواد الكيميائية المسببة للتآكل ، كما هو الحال في صناعات معالجة المواد الكيميائية أو الأغذية. لن تتدفق شبكة الشاشة أو تتدهور بمرور الوقت ، مما يضمن أداءً أطول ومتسقًا. يمنع السطح الأملس لمادة البولي يوريثان تراكم المواد والانسداد ، مما يقلل من الحاجة إلى التنظيف المتكرر. هذا لا يوفر فقط تكاليف الوقت والعمالة ولكن أيضًا يضمن أن الشاشة الاهتزازية تعمل في ذروة كفاءة. من مقاومة التآكل الفائقة وكفاءة الفحص إلى الحد من الضوضاء والمقاومة الكيميائية ، يوفر هذا النوع من شبكة الشاشة العديد من المزايا لمجموعة واسعة من الصناعات. من خلال الاستثمار في شبكة شاشة البولي يوريثان عالية الجودة ، يمكن للشركات تحسين عمليات الفحص الخاصة بها ، وزيادة الإنتاجية ، وتقليل تكاليف الصيانة على المدى الطويل. إن متانتها وأدائها وسهولة الصيانة تجعلها خيارًا شائعًا للصناعات التي تتطلع إلى تحسين عمليات الفحص الخاصة بها. من خلال فوائدها العديدة ، تعد شبكة شاشة البولي يوريثان استثمارًا ذكيًا للشركات التي تسعى إلى تحسين الكفاءة والإنتاجية في عملياتها.

نصيحة التثبيت والصيانة لشاشة شاشة البولي يوريثان المعيارية مزدوجة سطح السفينة

مقارنة بين شبكة شاشة البولي يوريثان المزدوجة سطح السفينة مع خيارات شاشة الشاشة الأخرى

عندما يتعلق الأمر باختيار شبكة الشاشة الصحيحة للشاشات الاهتزازية ، فهناك العديد من الخيارات المتاحة في السوق. أحد الخيارات الشائعة هو شبكة شاشة البولي يوريثان المعيارية المزدوجة. يوفر هذا النوع من شبكة الشاشة عددًا من المزايا على الخيارات الأخرى ، مما يجعلها خيارًا مفضلاً للعديد من الصناعات. البولي يوريثان هو مادة قوية ومرنة يمكنها تحمل قسوة تطبيقات الفحص الشاقة. هذا يعني أن شبكة الشاشة أقل عرضة لكسر أو التآكل بسرعة ، مما يؤدي إلى انخفاض تكاليف الصيانة والتعطل للمعدات الخاصة بك. يسمح التصميم المعياري لشبكة الشاشة بسهولة التثبيت والإزالة ، مما يجعل من السهل استبدال الألواح البالية أو التالفة. هذا يعني أنه يمكنك وسهولة ضبط أداء فحص شاشة الاهتزاز الخاصة بك لتلبية المتطلبات المحددة لتطبيقك. يتوفر هذا النوع من شبكة الشاشة في مجموعة واسعة من أحجام الفتح والتكوينات ، مما يتيح لك تخصيص أداء فحص شاشة الاهتزاز الخاصة بك لتناسب احتياجاتك الخاصة. سواء كنت تقوم بفحص جزيئات دقيقة أو مجاميع كبيرة ، فهناك خيار شبكة بولي يوريثان مقطوعة على سطح السفينة المزدوج المناسبة لك. إن مادة البولي يوريثان مقاومة للغاية للتآكل والتآكل ، مما يضمن أن شبكة الشاشة الخاصة بك ستستمر لفترة أطول وتؤدي أداءً أفضل في ظروف التشغيل القاسية. يمكن أن يؤدي ذلك إلى توفير كبير في التكاليف بمرور الوقت ، حيث لن تحتاج إلى استبدال شبكة الشاشة بشكل متكرر.

علاوة على ذلك ، من السهل التنظيف والصيانة. يمنع السطح الأملس لمادة البولي يوريثان تراكم المواد والتعمية ، مما يضمن أن شاشة الاهتزاز تعمل بكفاءة ذروة. يعد التنظيف المنتظم لشبكة الشاشة أمرًا بسيطًا ويمكن القيام به بسرعة ، مما يساعد على تقليل وقت التوقف وزيادة الإنتاجية إلى الحد الأقصى. إن المتانة ، وكفاءة الفحص ، والتعدد الاستخدامات ، ومقاومة التآكل ، وسهولة الصيانة تجعلها خيارًا فعالًا وموثوقًا باحتياجات الفحص الخاصة بك. سواء كنت تقوم بفحص المجاميع أو المعادن أو الفحم أو غيرها من المواد ، فإن شبكة شاشة البولي يوريثان المعيارية مزدوجة سطح السفينة يمكن أن تساعدك على تحقيق أداء الفحص الأمثل وزيادة إنتاجية المعدات الخاصة بك.

যখন স্পন্দিত স্ক্রিনগুলির জন্য সঠিক স্ক্রিন জালটি বেছে নেওয়ার কথা আসে, তখন বাজারে বেশ কয়েকটি বিকল্প পাওয়া যায়। একটি জনপ্রিয় পছন্দ হ’ল ডাবল ডেক মডুলার পলিউরেথেন স্ক্রিন জাল। এই ধরণের স্ক্রিন জাল অন্যান্য বিকল্পগুলির তুলনায় বেশ কয়েকটি সুবিধা দেয়, এটি অনেক শিল্পের জন্য পছন্দসই পছন্দ করে তোলে

পলিউরেথেন একটি শক্তিশালী এবং স্থিতিস্থাপক উপাদান যা ভারী শুল্ক স্ক্রিনিং অ্যাপ্লিকেশনগুলির কঠোরতা সহ্য করতে পারে। এর অর্থ হ’ল স্ক্রিন জালটি দ্রুত ভাঙার বা দ্রুত পরিধান করার সম্ভাবনা কম থাকে, যার ফলে আপনার সরঞ্জামগুলির জন্য কম রক্ষণাবেক্ষণ ব্যয় এবং ডাউনটাইম হয়

এর স্থায়িত্ব ছাড়াও, ডাবল ডেক মডুলার পলিউরেথেন স্ক্রিন জালও দুর্দান্ত স্ক্রিনিংয়ের দক্ষতা সরবরাহ করে। স্ক্রিন জালটির মডুলার ডিজাইনটি সহজেই ইনস্টলেশন এবং অপসারণের অনুমতি দেয়, এটি জীর্ণ বা ক্ষতিগ্রস্থ প্যানেলগুলি প্রতিস্থাপন করা সহজ করে তোলে। এর অর্থ হ’ল আপনি আপনার অ্যাপ্লিকেশনটির নির্দিষ্ট প্রয়োজনীয়তাগুলি পূরণের জন্য আপনার স্পন্দিত স্ক্রিনের স্ক্রিনিংয়ের কার্যকারিতা দ্রুত এবং সহজেই সামঞ্জস্য করতে পারেন

এই ধরণের স্ক্রিন জালটি খোলার আকার এবং কনফিগারেশনের বিস্তৃত পরিসরে উপলব্ধ, যা আপনাকে আপনার স্পন্দিত স্ক্রিনের স্ক্রিনিং পারফরম্যান্সকে আপনার নির্দিষ্ট প্রয়োজন অনুসারে কাস্টমাইজ করতে দেয়। আপনি সূক্ষ্ম কণা বা বৃহত সমষ্টিগুলি স্ক্রিন করছেন না কেন, আপনার জন্য সঠিক একটি ডাবল ডেক মডুলার পলিউরিথেন স্ক্রিন জাল বিকল্প রয়েছে

অন্যান্য স্ক্রিন জাল বিকল্পগুলির সাথে তুলনা করে যেমন বোনা তার বা ছিদ্রযুক্ত প্লেট, ডাবল ডেক মডুলার পলিউরেথেন স্ক্রিন জাল উচ্চতর পরিধানের প্রতিরোধের প্রস্তাব দেয়। পলিউরেথেন উপাদানগুলি ঘর্ষণ এবং জারা থেকে অত্যন্ত প্রতিরোধী, এটি নিশ্চিত করে যে আপনার স্ক্রিনের জাল দীর্ঘস্থায়ী হবে এবং কঠোর অপারেটিং পরিস্থিতিতে আরও ভাল পারফর্ম করবে। এটি সময়ের সাথে সাথে উল্লেখযোগ্য ব্যয় সাশ্রয় করতে পারে, কারণ আপনাকে প্রায়শই স্ক্রিন জাল প্রতিস্থাপনের প্রয়োজন হবে না

এছাড়াও, ডাবল ডেক মডুলার পলিউরেথেন স্ক্রিন জাল পরিষ্কার এবং রক্ষণাবেক্ষণ করা সহজ। পলিউরেথেন উপাদানের মসৃণ পৃষ্ঠটি উপাদান তৈরি এবং অন্ধকরণকে বাধা দেয়, এটি নিশ্চিত করে যে আপনার কম্পনকারী স্ক্রিনটি শিখর দক্ষতায় কাজ করে। স্ক্রিনের জাল নিয়মিত পরিষ্কার করা সহজ এবং দ্রুত করা যায়, ডাউনটাইম হ্রাস করতে এবং উত্পাদনশীলতা সর্বাধিকতর করতে সহায়তা করে

সামগ্রিকভাবে, ডাবল ডেক মডিউলার পলিউরেথেন স্ক্রিন জাল বিস্তৃত শিল্পের বিস্তৃত স্ক্রিনগুলির জন্য একটি উচ্চতর পছন্দ। এর স্থায়িত্ব, স্ক্রিনিংয়ের দক্ষতা, বহুমুখিতা, পরিধান প্রতিরোধের এবং রক্ষণাবেক্ষণের স্বাচ্ছন্দ্য এটিকে আপনার স্ক্রিনিংয়ের প্রয়োজনীয়তার জন্য একটি ব্যয়বহুল এবং নির্ভরযোগ্য বিকল্প হিসাবে তৈরি করে। আপনি সমষ্টি, খনিজ, কয়লা বা অন্যান্য উপকরণ স্ক্রিনিং করছেন কিনা, ডাবল ডেক মডুলার পলিউরেথেন স্ক্রিন জাল আপনাকে সর্বোত্তম স্ক্রিনিংয়ের কার্যকারিতা অর্জন করতে এবং আপনার সরঞ্জামগুলির উত্পাদনশীলতা সর্বাধিক করতে সহায়তা করতে পারে