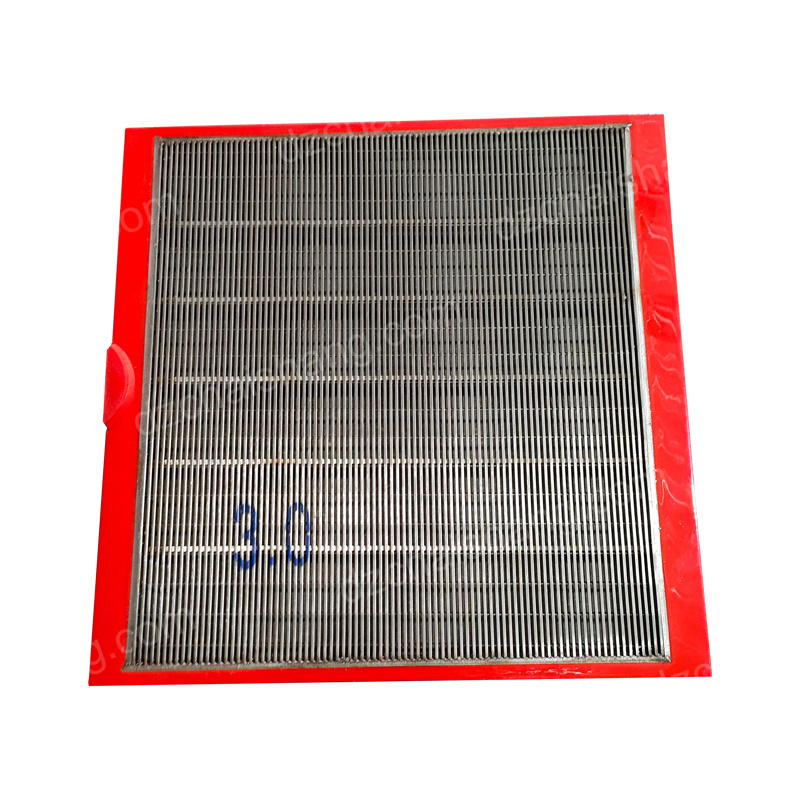

610×610 Metal screen plate

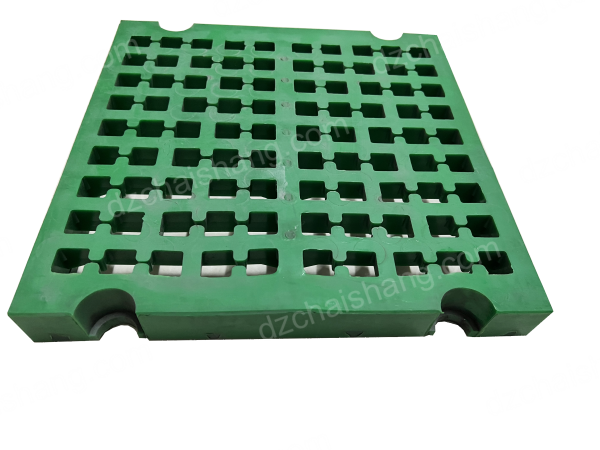

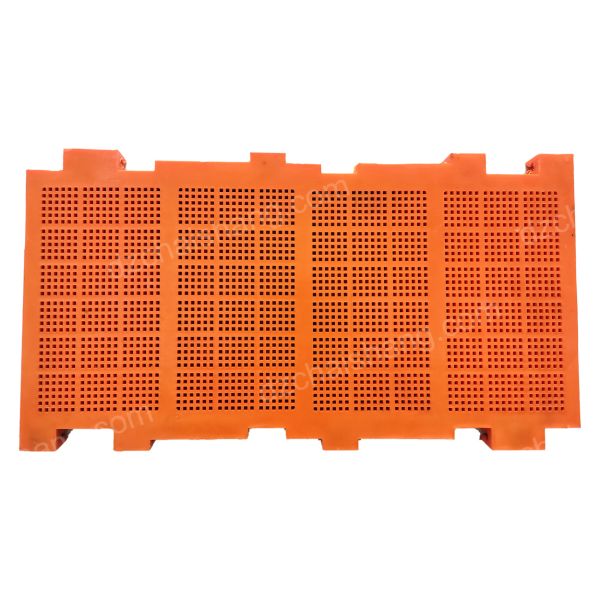

A modular polyurethane screen panel is a good choice for many screening circuits, especially well suited for wet or dry applications. Also available in a variety of formulations including softer compounds that minimize or eliminate blinding.

- Satisfaction Guaranteed

- Accurate dimensions

- Guaranteed installation

Description

A brief introduction to polyurethane-edged metal screen plates

The sieve plate is made of a plate structure with a slit screen surface. The slit screen surface is arranged by trapezoidal cross-section strips, and the sieve slits are smaller. Material: 304, 316, imported high-strength stainless steel Wedge wire.

Detailed information of polyurethane edged screen plate

Polyurethane edge screen plate

Polyurethane-edged screen plate is one of the dewatering screen products, also known as stainless steel slot screen, vibrating screen module, dewatering screen, etc. Polyurethane-edged screen plates are mainly used in high-frequency vibrating screen dehydration, clean coal screening, gangue separation and other aspects.

The screen mesh is a stainless steel welded slit type, and the screen wire is a trapezoidal wire that is wide at the top and narrow at the bottom. After welding and forming, the screen slit is a slit type, and the screen slit is narrow at the top and wide at the bottom, which can effectively dehydrate and remove media. The four sides of the screen plate are polyurethane-coated or rubber-coated structures. When installing, you only need to butt the screen plates one by one or install them directly on the mounting base, and combine them with side pressure plates, wedges, spacers, etc. to form a large screen surface. Because of the special properties of polyurethane – wear-resistant, strong plasticity, and telescopic type, the polyurethane-edged screen plate has a tight and solid screen surface structure, and there will be no coal leakage, loosening of the screen plate, etc.