振动聚氨酯模块化网采矿,振动器聚氨酯面板提供商矿物

استكشافكفاءةشبكة وحدات البولي يوريثان الاهتزازيةفيعمليات التعدين

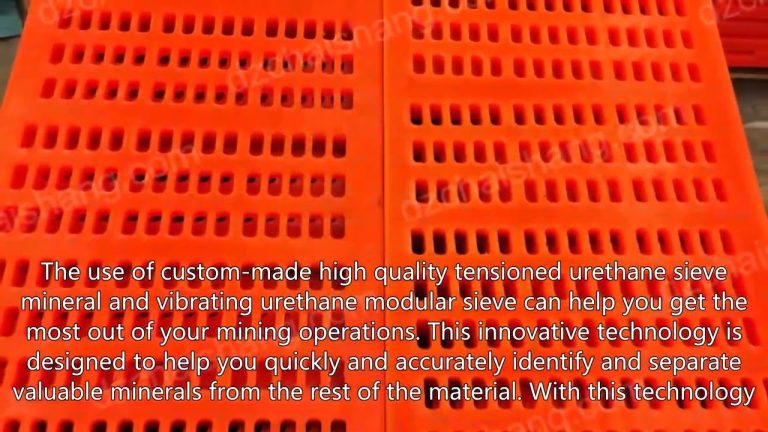

كانت صناعة التعدين دائمًافيطليعةتبني التقنيات المبتكرة لتعزيزالكفاءة التشغيليةوالإنتاجية。 إحدىهذهالأعجوبة التكنولوجيةالتي أحدثت ثورة في قطاع التعدين هي شبكة وحدات البولي يوريثين المهتزة。 أدىحلالغربلةالمتقدم هذا، المقدم من كبار موفري ألواح اليوريثان الهزازة،إلىتحسين عمليات استخراج المعادنبشكلكبير،مما يجعلهاأكثركفاءة وفعاليةمنحيثالتكلفة。 إنهمصنوعمنمادة البولي يوريثينعالية الجودة، وهي مادة معروفةبمتانتها الاستثنائية ومقاومتهاللتآكل。 وهذايجعلالشبكة مثاليةللتعاملمع الأحمالالثقيلة والموادالكاشطة الشائعةفيعمليات التعدين。

دور مقدمي ألواح اليوريثانالهزازةفي استخلاصالمعادن

تعد صناعة استخراج المعادنقطاعًامعقدًا ومعقدًايعتمدبشكل كبيرعلىالتكنولوجيا المتقدمةوالحلول المبتكرةلتحسين العمليات。 أحد هذه الابتكارات التي أحدثت ثورة في الصناعةهواستخدام شبكة وحدات البولي يوريثينالاهتزازيةفي عملياتالتعدين。 هذهالتقنية،التي يقدمهاموفروألواح اليوريثانالهزازة، عززت بشكل كبير كفاءة وفعاليةعمليات استخراجالمعادن。 تمتصميمهذهالألواح لتحملالظروفالقاسية لعمليات التعدين، مما يوفرالمتانةوطول العمر الذي يفوق بكثير المواد التقليديةمثل الفولاذ。 تتميزالألواحبأنها مقاومةللتآكلوالتآكل ودرجات الحرارة القصوى، مما يجعلها خيارًامثاليًالبيئة المناجمالمتطلبة。

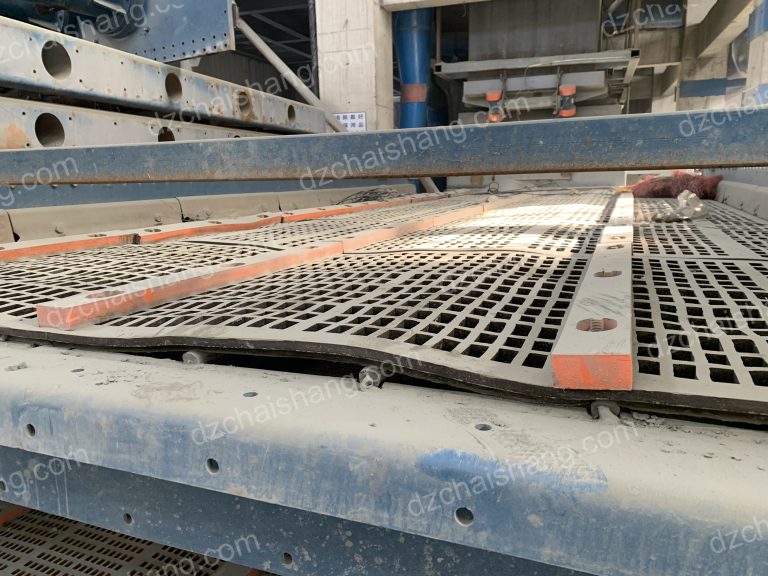

إن دور مزودي ألواح اليوريثانالهزازةفي استخراج المعادنمتعدد الأوجه。 أولاً، هم مسؤولونعن إنتاج وتوريد هذه الألواح。 يتضمنذلكاستخداممادة البولي يوريثينعالية الجودة، وهي مادة معروفةبقوتها ومرونتها。 يتم بعد ذلك تشكيل البولي يوريثينفي ألواح معيارية، والتي تمتصميمهالتتلاءم بسلاسةمعمجموعة متنوعةمنمعداتالفحص。 يتيح التصميمالمعياري سهولةاستبدالاللوحات الباليةأوالتالفة، مما يقلل من وقت التوقف عنالعملويزيد الإنتاجيةإلىالحد الأقصى。

ثانيًا، يقدم مزودو ألواح اليوريثان الهزازةالدعمالفني والخبرةلشركات التعدين。 يتضمنذلكتقديم المشورةبشأنأفضل تكوينللوحةلعملية معينة، وتوفير إرشادات التثبيت، وتقديم خدمات الصيانةوالإصلاح。 يضمنهذاالمستوىمن الدعماستخدامالألواح بفعاليةوكفاءة،مما يساهم في النجاح الشامل لعمليةالتعدين。

إناستخدامشبكةوحدات البولي يوريثين الاهتزازيةفيالتعدين لهفوائدعديدة。 توفر الألواح أداء فحص فائقًا، مع إمكانات الاهتزازالتيتسمح بالفصلالفعال للجزيئات ذات الأحجام المختلفة。 وينتج عن ذلك جودة أعلى للمعادنالمستخرجة وعمليةتعدينأكثر كفاءة。 بالإضافةإلىذلك،فإن متانةالألواحتقللمن الحاجةإلى الاستبدالات المتكررة، مما يؤدي إلى توفيركبيرفي التكاليف。

علاوةعلى ذلك، يساهم استخدام ألواح اليوريثان الهزازةفياستدامة عملياتالتعدين。 الألواح قابلةلإعادة التدوير،ممايقللمن التأثيرالبيئيلعملية التعدين。 علاوةعلىذلك،فإن متانتهاوعمرهاالطويل يعنيان هدر كمية أقل من المواد، مما يساهم في عمليةأكثراستدامة。

في الختام، يلعبمزودو ألواح اليوريثان الهزازدورًاحاسمًافي صناعةاستخراجالمعادن。 أنهاتوفرمنتجًايعزز كفاءةوفعاليةعمليات التعدين، بينماتقدم أيضًاالدعمالفني والخبرة。 يعد استخدام شبكة وحدات البولي يوريثين الاهتزازيةفيالتعدين بمثابةشهادةعلى التزامالصناعة بالابتكاروالاستدامة。 معاستمرارنموالطلب علىالمعادن،فإندور مزودي ألواح اليوريثان الهزازةسيصبحبلاشك أكثرأهمية。 إنمساهمتهمفيالصناعة لا تقدر بثمن، حيث توفر حلولاً لا تعمل على تحسينالعملياتفحسب، بلتساهمأيضًافيتحقيق مستقبلأكثراستدامة.

其次,振动器聚氨酯面板供应商为采矿公司提供技术支持和专业知识。这包括就特定操作的最佳面板配置提供建议、提供安装指导以及提供维护和维修服务。这种水平的支撑确保面板得到有效和高效的使用,有助于采矿作业的整体成功。

在采矿中使用振动聚氨酯模块化网有许多好处。该面板提供卓越的筛分性能,其振动能力可以有效分离不同尺寸的颗粒。这使得提取的矿物质量更高,采矿过程更高效。此外,面板的耐用性减少了频繁更换的需要,从而显着节省成本。

此外,振动器聚氨酯面板的使用有助于采矿作业的可持续性。这些面板是可回收的,减少了采矿过程对环境的影响。此外,它们的耐用性和较长的使用寿命意味着更少的材料浪费,有助于实现更可持续的运营。

总而言之,振动器聚氨酯面板供应商在矿物开采行业中发挥着至关重要的作用。他们提供的产品可以提高采矿作业的效率和效益,同时还提供技术支持和专业知识。在采矿业中使用振动聚氨酯模块化网证明了该行业对创新和可持续发展的承诺。随着对矿物的需求持续增长,振动器聚氨酯板供应商的作用无疑将变得更加重要。他们对行业的贡献是无价的,提供的解决方案不仅可以优化运营,还可以为更加可持续的未来做出贡献。