flotation machine impeller and cover plate,PU impeller,flotation machine stator

How the PU Impeller and Cover Plate Improve Flotation Machine Performance

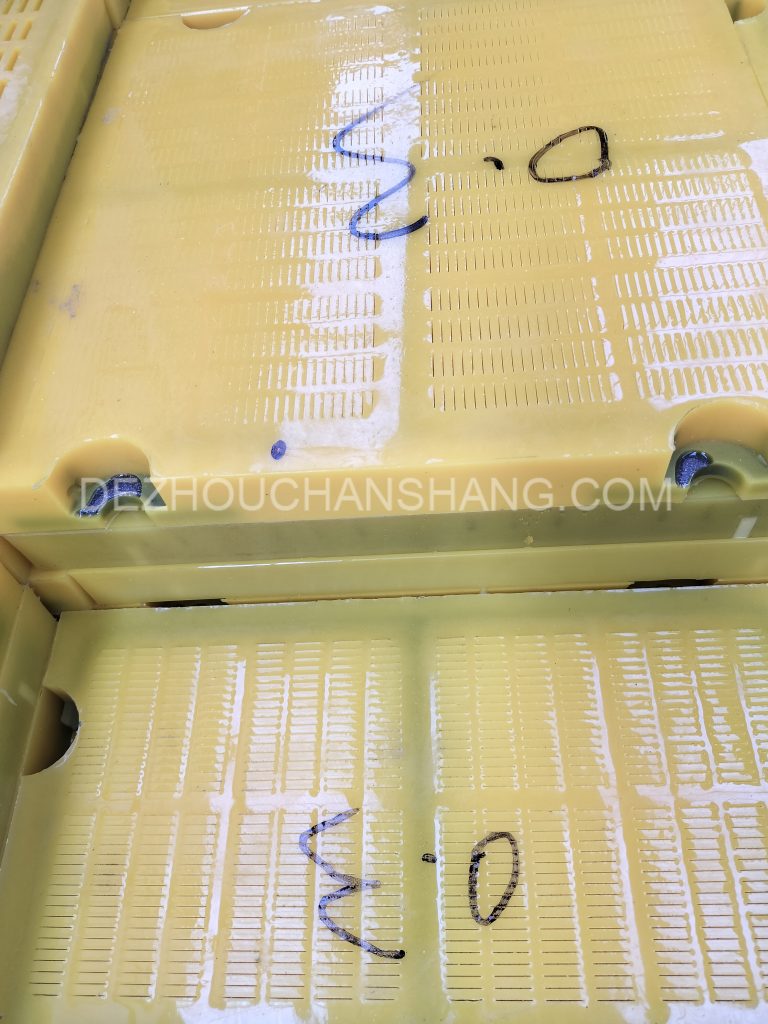

The PU impeller and cover plate are important components of a flotation machine. They are designed to improve the performance of the machine by increasing the efficiency of the flotation process.

The PU impeller is a key component of the flotation machine. It is responsible for creating the necessary turbulence in the flotation cell to ensure that the particles are properly mixed and suspended in the water. The impeller is designed to be highly efficient and to reduce the amount of energy required to operate the machine.

The cover plate is also an important component of the flotation machine. It is designed to reduce the amount of air that is lost during the flotation process. This helps to reduce the amount of energy required to operate the machine and also helps to improve the efficiency of the flotation process.

Together, the PU impeller and cover plate help to improve the performance of the flotation machine. They are designed to reduce the amount of energy required to operate the machine and to increase the efficiency of the flotation process. This helps to ensure that the machine is able to produce the desired results.

The Benefits of Using a Flotation Machine Stator for Improved Separation Efficiency

A flotation machine stator is an important component of a flotation machine, as it helps to create the turbulence necessary for effective separation of particles. The stator is a stationary component that is typically made of rubber or plastic and is located in the center of the flotation cell.

The use of a flotation machine stator can provide several benefits for improved separation efficiency. First, the stator helps to create a turbulent flow in the flotation cell, which helps to keep the particles suspended in the liquid. This allows for more efficient separation of the particles, as they are more easily separated from the liquid.

Second, the stator helps to reduce the amount of air bubbles that are created in the flotation cell. This helps to reduce the amount of energy required to separate the particles, as the air bubbles can act as a barrier to the particles.

Third, the stator helps to reduce the amount of foam that is created in the flotation cell. Foam can interfere with the separation process, as it can cause particles to stick together and reduce the efficiency of the separation process.

Finally, the stator helps to reduce the amount of time required to complete the separation process. By creating a turbulent flow in the flotation cell, the particles are more easily separated from the liquid, which reduces the amount of time required to complete the separation process.

Overall, the use of a flotation machine stator can provide several benefits for improved separation efficiency. By creating a turbulent flow in the flotation cell, reducing the amount of air bubbles and foam, and reducing the amount of time required to complete the separation process, the use of a flotation machine stator can help to improve the efficiency of the separation process.