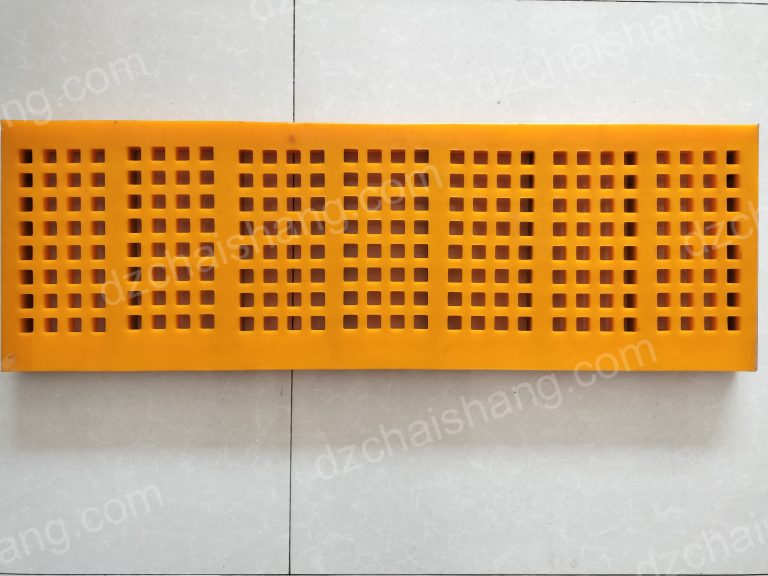

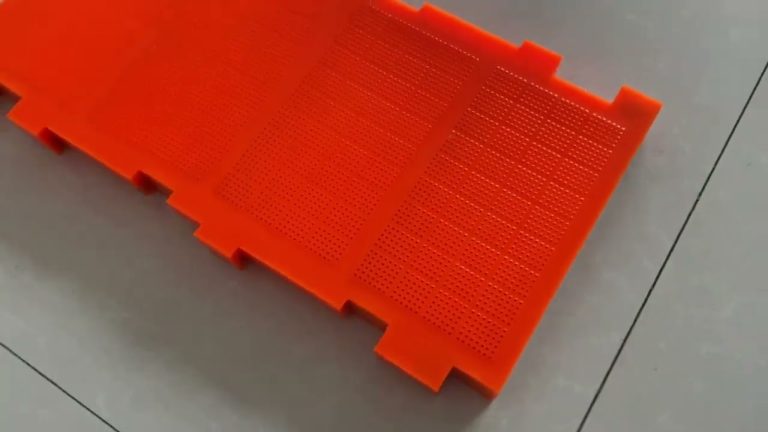

Sàng rây rung tuyến tính urethane, lưới màn hình polyurethane

فوائد استخدام المناخب الاهتزاز الخطي يوريتان للتطبيقات الصناعية

يوريتان الخطيين ، أصبحت المناخب الاهتزازي ، والمعروفة أيضًا باسم شبكة شاشة البولي يوريثان ، شائعة بشكل متزايد في التطبيقات الصناعية بسبب فوائدها العديدة. هذه المناخل مصنوعة من مواد يوريتان عالية الجودة ، والتي توفر المتانة والأداء الاستثنائيين. في هذه المقالة ، سوف نستكشف مزايا استخدام المناخل الاهتزازية الخطي في يوريتان في مختلف الإعدادات الصناعية. تشتهر مادة يوريتان بمقاومة التآكل الممتازة ، مما يجعلها مثالية للتطبيقات التي يتعرض فيها الغربال لمستويات عالية من البلى. هذا يعني أن المناخب الاهتزاز الخطي يوريتان لها عمر أطول مقارنةً بالحرارة المعدنية التقليدية ، مما يقلل من الحاجة إلى بدائل وصيانة متكررة. هذا يجعلها مناسبة للاستخدام في الصناعات حيث يتلامس الغربال مع المواد المسببة للتآكل أو المواد الكيميائية. إن مادة يوريتان مقاومة لمجموعة واسعة من المواد الكيميائية ، مما يضمن أن الغربال يبقى في حالة مثالية حتى في البيئات القاسية. تتيح مرونتها تخصيصًا سهلاً لتناسب متطلبات محددة ، مثل أحجام أو أشكال مختلفة. هذا التنوع يجعل من المناخس الخطي الاهتزاز من اليوريتان حلًا متعدد الاستخدامات لمجموعة واسعة من التطبيقات الصناعية. تتيح الطبيعة المرنة لمواد يوريتان الفحص الفعال للمواد ، مما يؤدي إلى ارتفاع إنتاجية وتحسين جودة المنتج. هذا يمكن أن يؤدي إلى زيادة الإنتاجية وتوفير التكاليف للعمليات الصناعية.

كيف تعمل شبكة شاشة البولي يوريثان على تحسين الكفاءة في الاهتزازات

بشكل عام ، توفر شبكة شاشة البولي يوريثان مجموعة من المزايا التي تجعلها خيارًا مثاليًا للهتزاز من المناخل في الصناعات التعدين والمجموعة. تسهم المتانة ، وكفاءة الفحص ، ومقاومة خصائص الحد من الضوضاء ، وتخفيض الضوضاء ، في تحسين الأداء والإنتاجية. يمكن للمشغلين الاعتماد على شبكة شاشة البولي يوريثان لتعزيز كفاءة من نقاشهم الاهتزازي وتحقيق نتائج أفضل من حيث الإنتاجية وجودة المنتج والتكاليف التشغيلية. خصائصه الفريدة تجعلها بديلاً فائقًا لشاشات شبكة الأسلاك التقليدية ، مما يوفر المتانة ، ودقة الفحص ، ومقاومة التعمية ، وتقليل الضوضاء. يمكن للمشغلين الاستفادة من الأداء والإنتاجية المعززة التي توفرها شبكة شاشة البولي يوريثان ، مما يجعلها استثمارًا قيمًا لأي تطبيق غربال يهتز.

সামগ্রিকভাবে,পলিউরেথেনস্ক্রিনসুবিধাদেয়এটিএবংশিল্পগুলিতেকম্পনেরজন্যজন্যআদর্শআদর্শ এর,স্ক্রিনিং,অন্ধদেরঅন্ধদেরএবংহ্রাসসমস্তউন্নতএবংরাখে।অবদান অপারেটররাতাদেরদক্ষতাবাড়াতেবাড়াতেএবংথ্রুপুটএবংএবংএবংব্যয়েরক্ষেত্রেআরওভালভালফলাফলঅর্জনকরতেকরতেপলিউরেথেনপারেপারেপারেপারেপারেপারে উপসংহারে,পলিউরেথেনপলিউরেথেনকম্পনকারীদক্ষতারউন্নতিরএকটিএকটিএবংএবংসমাধান।传统的তিহ্যবাহীতিহ্যবাহীতিহ্যবাহীতারেরজালস্ক্রিনগুলিরউচ্চতরবিকল্পহিসাবে,স্থায়িত্ব,স্ক্রিনিংয়ের,অন্ধ,অন্ধঅন্ধঅন্ধঅন্ধঅন্ধকরারকরারকরারপ্রতিরোধএবংপ্রস্তাব অপারেটররাপলিউরেথেনজালকরেএমনকর্মক্ষমতাএবংথেকেউপকৃতহতেহতেহতেপারেহতেহতেহতেকোনওকোনওচালনীচালনীচালনীজন্যজন্যতোলেতোলে