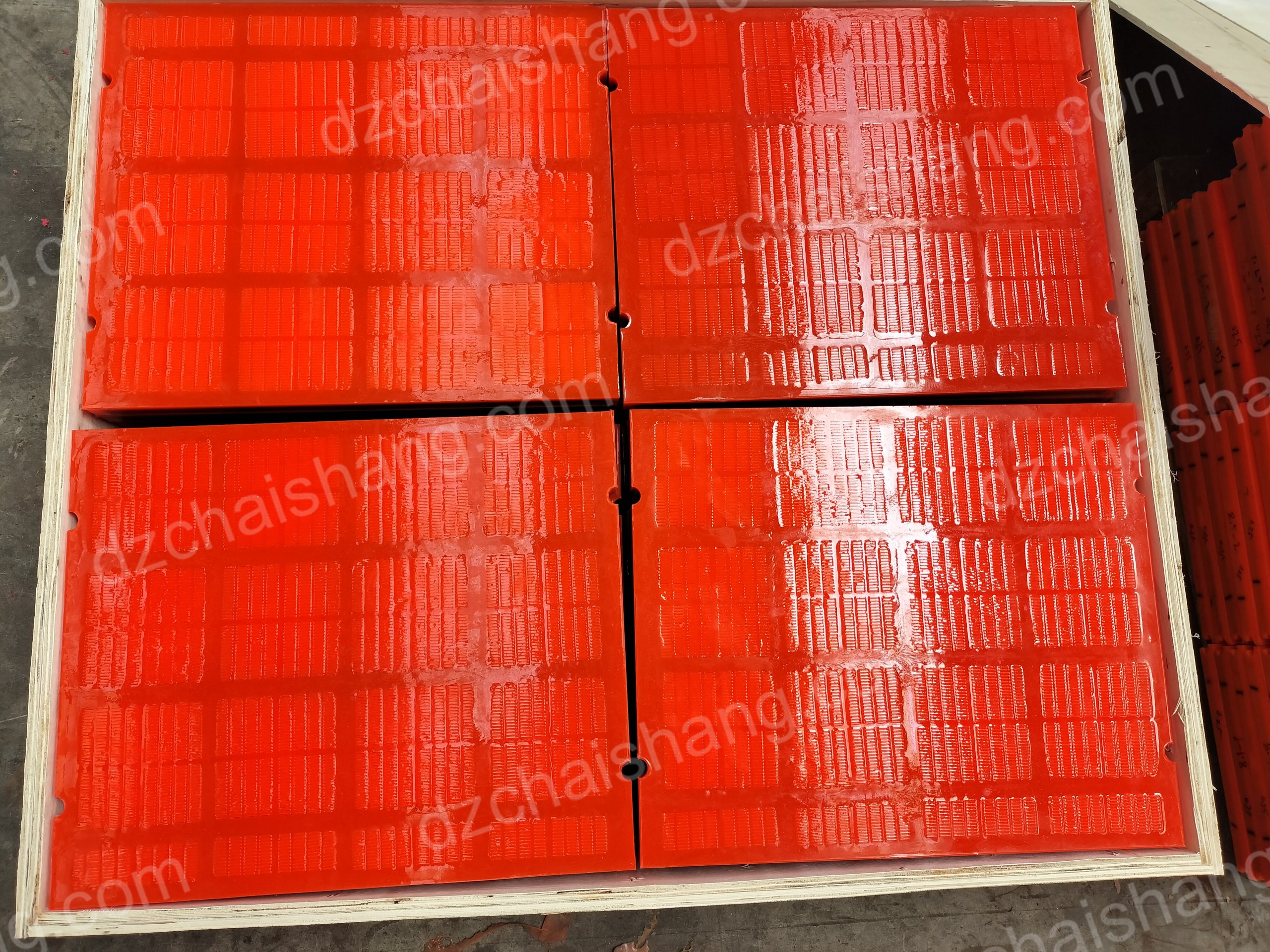

Khai thác sàng cao su giá rẻ,Nhà sản xuất khai thác tấm PU rung tròn

= ” أكثرفعاليةمنحث ..ПУ .. .. المتطلبات،تستف ي .. ا=u0644 بكفاءة =u0641=u062d=u0633ب، بل تتɈ أيضًامعالتخطيط المالي وأهداف الاستدامة。 ومن خلا دمج هذه المواد “

= ” أكثرفعاليةمنحث ..ПУ. . . المتطلبات،تستف ي ..= ي بكفاءة =u0641=u062d=u0633ب، بل تتɈ أيضًامعالتخطيط المالي وأهداف الاستدامة。 ومن خلا هذه المواد ” . .

= ” أكثرفعاليةمنحث ..ПУ .. .. المتطلبات،تستف ي .. ا=u0644 بكفاءة =u0641=u062d=u0633ب، بل تتɈ أيضًامعالتخطيط المالي وأهداف الاستدامة。 ومن خلا دمج هذه المواد “