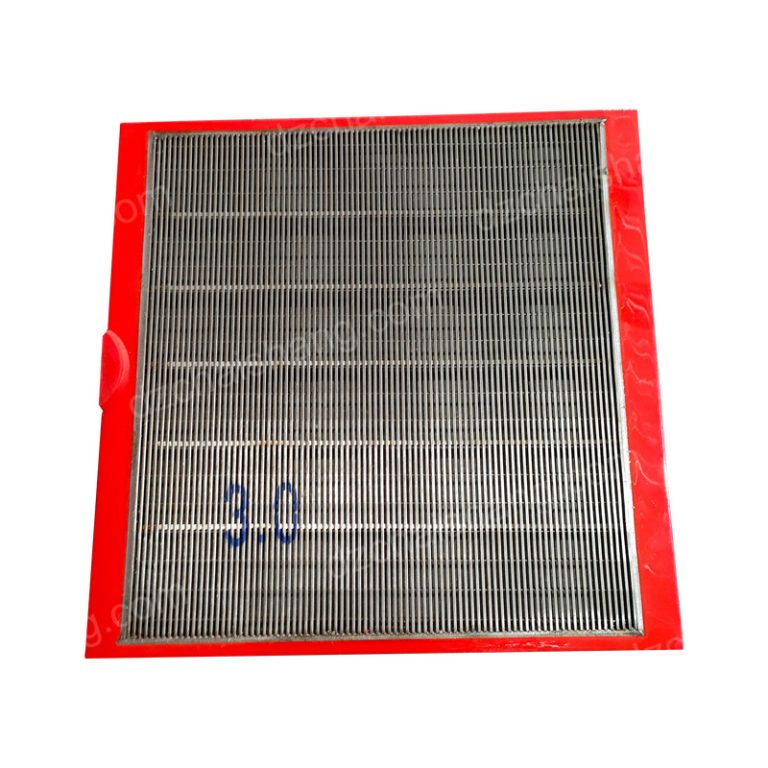

urethane screen

The Benefits of Using urethane screens in Industrial Applications

Urethane screens have become increasingly popular in industrial applications due to their numerous benefits. These screens, made from a type of polyurethane material, offer a range of advantages over traditional metal screens. In this article, we will explore the benefits of using urethane screens in industrial applications.

One of the primary advantages of urethane screens is their durability. Unlike metal screens, which can corrode or wear out over time, urethane screens are highly resistant to abrasion and chemicals. This makes them ideal for use in industries where harsh conditions are common, such as mining or construction. Urethane screens can withstand heavy loads and high impact, ensuring a longer lifespan and reduced maintenance costs.

Another benefit of urethane screens is their flexibility. Unlike rigid metal screens, urethane screens can be molded into various shapes and sizes to fit specific applications. This flexibility allows for greater customization and ensures a perfect fit for each industrial process. Additionally, urethane screens can be easily modified or repaired if needed, further enhancing their versatility.

Urethane screens also offer superior screening efficiency. The unique properties of urethane material allow for finer particle separation, resulting in more accurate and precise screening. This is particularly important in industries where the quality of the final product is crucial, such as pharmaceuticals or food processing. Urethane screens can effectively remove unwanted particles and impurities, ensuring a higher quality end product.

In addition to their durability, flexibility, and screening efficiency, urethane screens also provide excellent noise reduction. The polyurethane material absorbs vibrations and reduces noise levels, creating a quieter working environment. This is especially beneficial in industries where noise pollution can be a concern, such as manufacturing or automotive.

Furthermore, urethane screens are lightweight compared to their metal counterparts. This makes them easier to handle and install, reducing labor costs and improving overall efficiency. The lightweight nature of urethane screens also means less strain on equipment, resulting in reduced energy consumption and increased productivity.

Urethane screens are also known for their resistance to clogging. The unique design of these screens allows for self-cleaning, preventing material buildup and blockages. This ensures a continuous and uninterrupted screening process, minimizing downtime and maximizing productivity.

Lastly, urethane screens are environmentally friendly. The polyurethane material used in their construction is non-toxic and recyclable, making them a sustainable choice for industrial applications. By choosing urethane screens, companies can contribute to a greener and more sustainable future.

In conclusion, urethane screens offer a range of benefits that make them an excellent choice for industrial applications. Their durability, flexibility, screening efficiency, noise reduction, lightweight nature, resistance to clogging, and environmental friendliness make them a superior alternative to traditional metal screens. By investing in urethane screens, companies can improve their operational efficiency, reduce maintenance costs, and enhance the quality of their products.