cheapest PU screen panel minerial

Pros and Cons of Using Cheapest PU Panel Material for Mineral Processing

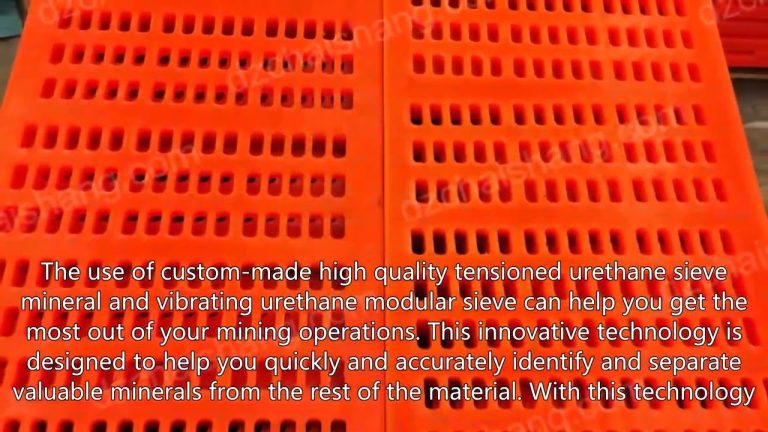

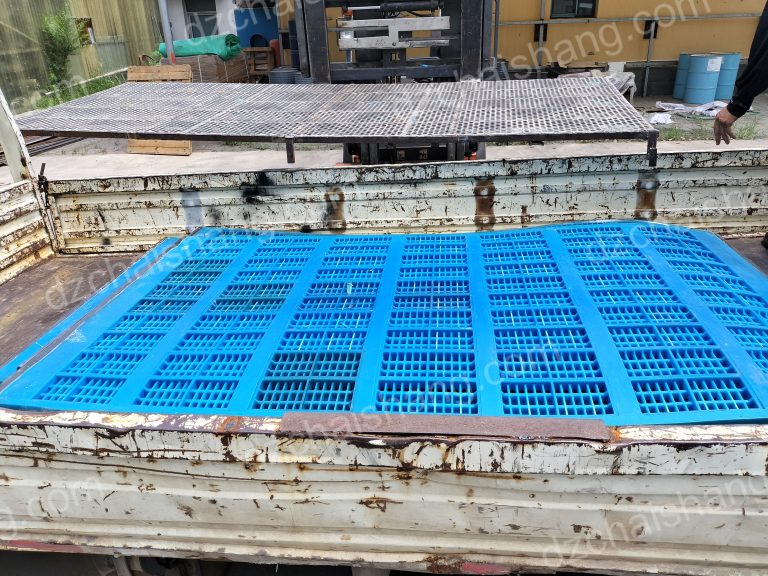

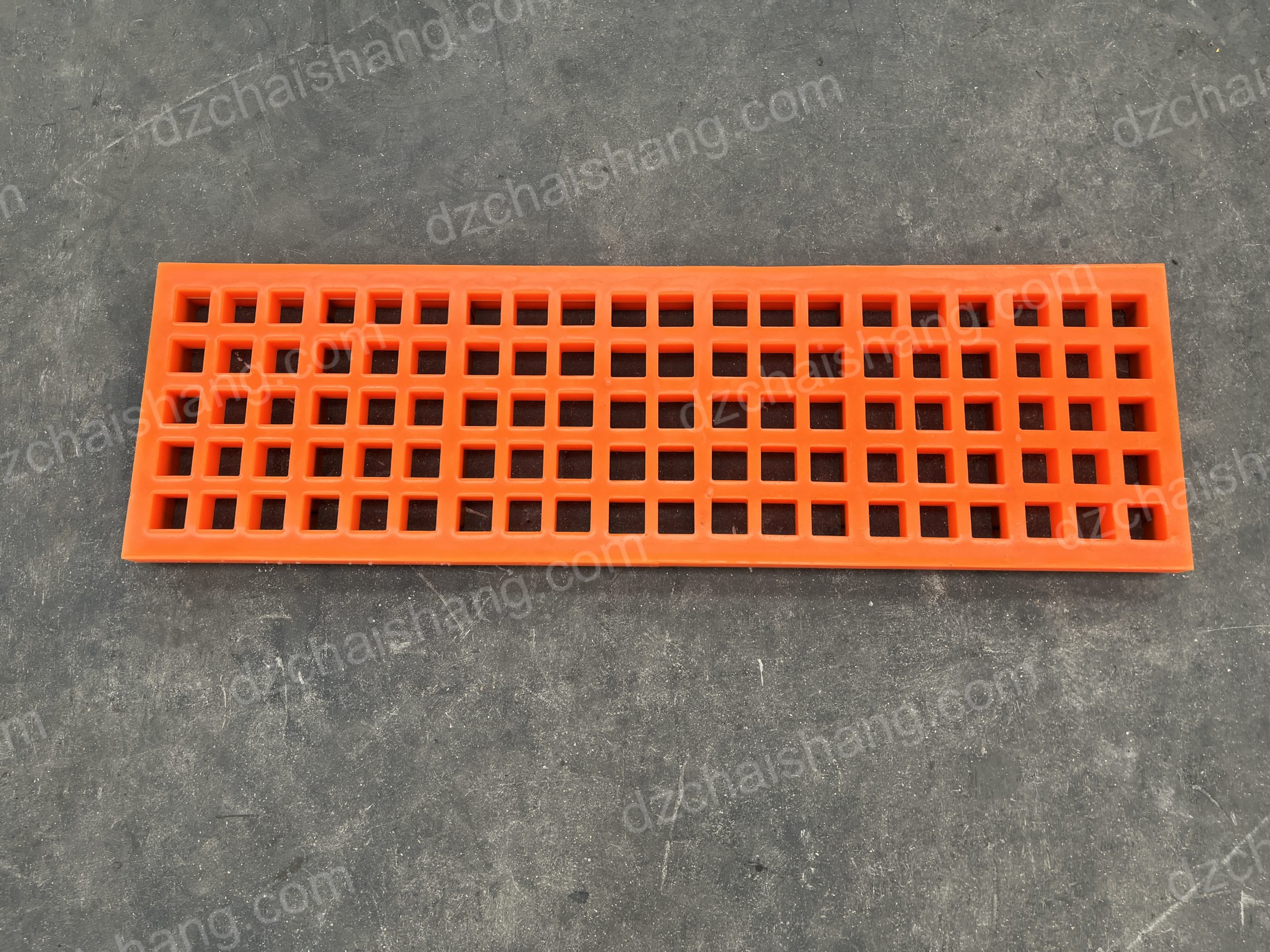

When it comes to mineral processing, choosing the right materials for your equipment is crucial to ensure efficiency and cost-effectiveness. One popular material used in panels for mineral processing is polyurethane (PU). PU panels are known for their durability, flexibility, and resistance to abrasion, making them a popular choice for many mining operations. However, there are pros and cons to using the cheapest PU panel material for mineral processing.

One of the main advantages of using the cheapest PU panel material is its cost-effectiveness. PU is generally more affordable than other materials such as rubber or steel, making it an attractive option for companies looking to save on costs. This can be especially beneficial for smaller mining operations or those operating on a tight budget.

In addition to being cost-effective, PU panels are also known for their durability. PU is a strong and resilient material that can withstand the harsh conditions of mineral processing, including high temperatures, corrosive chemicals, and abrasive materials. This durability can help extend the lifespan of your equipment and reduce the need for frequent replacements, saving you time and money in the long run.

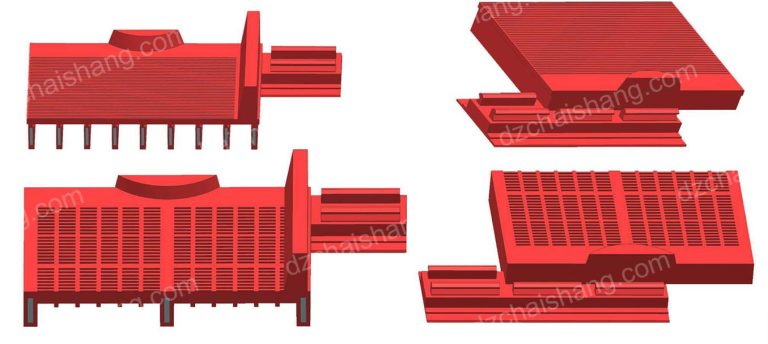

Furthermore, PU panels are flexible and easy to work with, making them ideal for customizing to fit specific processing needs. PU can be molded into various shapes and sizes, allowing for greater flexibility in design and installation. This flexibility can help improve the efficiency and effectiveness of your mineral processing operations, leading to higher productivity and better overall results.

Despite these advantages, there are some drawbacks to using the cheapest PU panel material for mineral processing. One potential downside is that PU may not be as resistant to wear and tear as other materials such as rubber or steel. While PU is durable, it may not hold up as well over time in extremely harsh or abrasive conditions, leading to more frequent replacements and maintenance.

Another drawback of using the cheapest PU panel material is that it may not offer the same level of performance as higher-quality materials. Cheaper PU panels may be more prone to warping, cracking, or breaking under heavy loads or extreme conditions, which can impact the efficiency and effectiveness of your mineral processing operations.

In conclusion, there are both pros and cons to using the cheapest PU panel material for mineral processing. While PU is cost-effective, durable, and flexible, it may not offer the same level of performance or longevity as other materials. It is important to weigh these factors carefully and consider your specific processing needs before making a decision on which material to use for your panels. Ultimately, choosing the right material for your equipment is essential to ensuring the success and efficiency of your mineral processing operations.