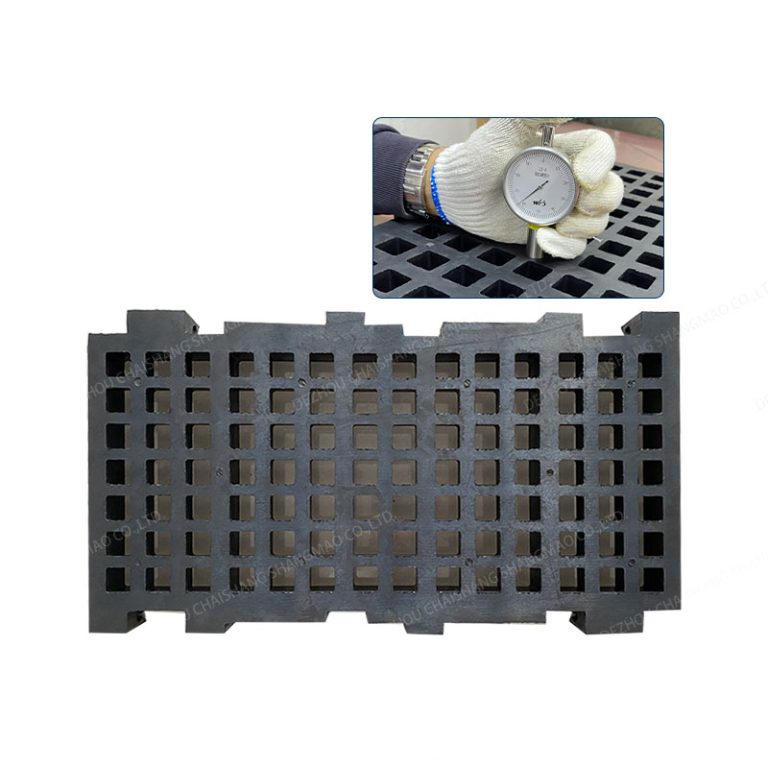

khai thác lưới màn hình Polyurethane, lưới sàng

= .. ” تجعلهاخيارًامثا’ لعملياتالتعدن。 بدءًامنمقاومتها الفائقةللتآكل ومرونتهاوحتىكفا) .. .. .. .. .. .. .. .. .. صناعةالتعدين。 منخلالالاستثمارف شبكةشاشةالبولي… تكاليفالصيانة، وتعزيزالإنتاجية الإجمالية。

= .. ” تجعلهاخيارًامثا’ لعملياتالتعدن。 بدءًامنمقاومتها الفائقةللتآكل ومرونتهاوحتىكفا) الفحصالعاليةوخ

= .. ” تجعلهاخيارًامثا’ لعملياتالتعدن。 بدءًامنمقاومتها الفائقةللتآكل ومرونتهاوحتىكفا) .. .. .. .. .. .. صناعةالتعدين。 منخلالالاستثمارف شبكةشاشةالبولي… تكاليفالصيانة، وتعزيزالإنتاجية الإجمالية。

= .. ” تجعلهاخيارًامثا’ لعملياتالتعدن。 بدءًامنمقاومتها الفائقةللتآكل ومرونتهاوحتىكفا) الفحصالعاليةوخ