Nouveau panneau de maille de tamis de déshydratation en polyuréthane

فوائدوتطبيقات التصميمالجديدللوحة شبكةشاشةنزحالمياهمن مادةالبولييوريثين

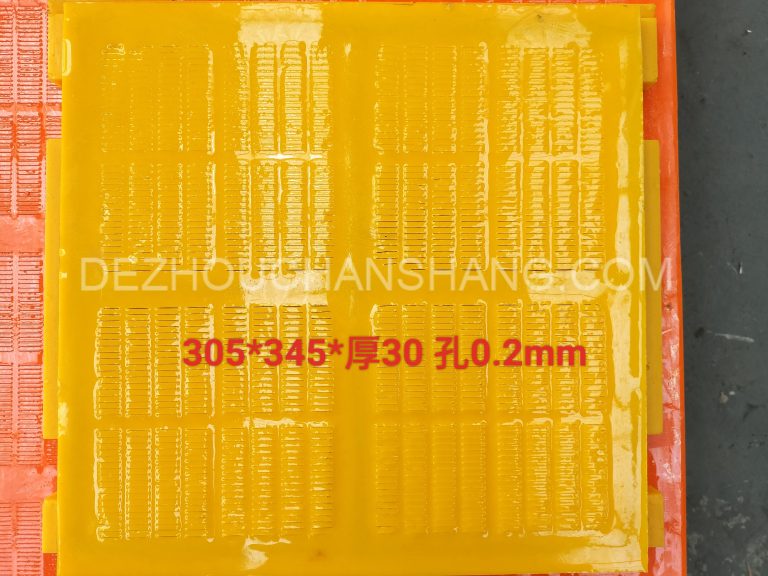

تعد لوحة شبكة شاشة نزح المياهمنمادةالبولي يوريثينذاتالتصميم الجديد منتجًا ثوريًا يقدم العديد من الفوائد والتطبيقات عبر مختلف الصناعات。 تمتصميمهذهاللوحة الشبكيةالمبتكرة لتوفيرأداءفائقفي عمليات نزح المياه، مما يجعلهامكونًاأساسيًا في العمليات التي تتطلب إزالةالرطوبةبكفاءة。 مصنوعة من مادة البولي يوريثينعاليةالجودة، هذهاللوحةالشبكية للشاشةمقاومةللتآكل والتمزق، ممايضمنعمر خدمةطويلحتىفيظل الظروفالقاسية。 تعتبرهذهالمتانةمهمة بشكل خاص في صناعات مثل التعدينواستغلال المحاجر، حيث تتعرض المعدات بشكلمتكرر للموادالكاشطة。 يساعد البناءالقوي للوحةشبكةالشاشة المصنوعةمنمادة البولي يوريثينعلى تقليلتكاليفالصيانة ووقت التوقف عن العمل، وبالتاليتعزيز الإنتاجيةالإجمالية。 مادةالبولييوريثين مقاومةبطبيعتهاللماء والزيوت والمواد الكيميائيةالأخرى، ممايجعلهامادةمثالية لتطبيقاتنزحالمياه。 لاتعملهذهالمقاومة للتآكلعلىإطالةعمر لوحةشبكةالشاشةفحسب، بلتضمنأيضًاالحفاظ علىفعاليتهابمرور الوقت。 ونتيجةلذلك،يمكن للصناعات التي تتعامل معالموادالمسببة للتآكلأنتعتمدعلى لوحةشبكةالغربلةهذه لتعملبشكلمتسقدون التعرضلخطرالتدهور。 يسمح التصميمالفريد لشبكةالشاشةبأقصىقدر منتصريفالمياهمع الاحتفاظبالجزيئات الصلبة。 تعدعمليةالفصل الفعالةهذهأمرًابالغ الأهميةفيتطبيقاتمثل غسلالرمالومعالجة المعادنوإدارة النفايات。 منخلالإزالةالرطوبة بشكل فعال، تساعد لوحة شبكةالشاشةالمصنوعة من مادة البولي يوريثين علىتحسينجودةالمنتج النهائيوتقليل التأثيرالبيئي للعملية。 متطلبات。 وهي متوفرة بأحجام وتكويناتمختلفة للفتحة، ممايسمح بتخصيصهالأنواع مختلفةمنالمواد وعملياتنزحالمياه。 هذهالمرونةتجعلها مناسبةلمجموعةواسعة منالتطبيقات،بدءًامن فصلالجسيماتالدقيقة فيصناعةالأغذية والمشروبات وحتى نزح المياهللخدمةالشاقة فيقطاعالبناء。

تمتد تطبيقات اللوحة الشبكيةذاتالتصميم الجديد من مادة البولي يوريثينلنزحالمياه إلى ما هو أبعد من الإعداداتالصناعية。 كماأنهاتستخدمفي العمليات الزراعية لنزح المياهمن المحاصيلوالتربة، وكذلكفي محطات معالجة مياهالصرفالصحي البلديةلنزحالمياهمن الحمأة。 إنقدرةلوحةشبكة الشاشةعلىالتعاملمع الموادوالظروف المختلفةتجعلهاأداة قيمةفيتحسينالكفاءة والاستدامةفيمختلف القطاعات。 الذي يقدم العديد من الفوائدوالتطبيقات。 إنمتانتهومقاومته للتآكلوكفاءةنزح المياهتجعلهمكونًالا غنى عنه في الصناعات التي تتطلب إزالة فعالة للرطوبة。 بالإضافةإلىذلك،فإن تنوعهاوقابليتها للتخصيصتسمحلها بتلبيةالاحتياجات المتنوعةلمختلف القطاعات。 معاستمرارالصناعاتفي البحث عن طرق لتعزيز الإنتاجية والاستدامة،تبرزلوحة شبكةشاشةنزحالمياهمن مادةالبولييوريثين ذات التصميم الجديد كخيارموثوق وفعال.

نصائحالتثبيت للتصميمالجديدللوحة شبكةشاشةنزحالمياهمن مادةالبولييوريثين

تعد لوحة شبكة شاشة نزح المياهمنمادةالبولي يوريثينذاتالتصميم الجديد حلاً متطورًا مصممًالتعزيزكفاءة وفعاليةتطبيقاتنزح المياهفيمختلف الصناعات، بما في ذلك عمليات التعدينوالرمل والحصىومعا لجةالركام。 يوفرهذاالمنتج المبتكر أداءً فائقًا ومتانةوسهولةفي التركيبمقارنةًبمواد الفحصالتقليدية。 لضمانالأداءالأمثل وطول العمر، من الضروري اتباعإرشاداتالتثبيت المناسبة。

أولاً، من المهم إعداد السطح حيث سيتم تركيب لوحةشبكيةلشاشةنزح المياهمنمادةالبولي يوريثين。 يجبأنيكونالسطح نظيفًاوناعمًا

بالإضافةإلى نصائح التثبيت المذكورةأعلاه،تعد الصيانةالمنتظمة أيضًاأمرًاضروريًا لزيادةأداءومتانة اللوحةالشبكيةذات التصميمالجديدمنمادة البولي يوريثينلنزح المياه。 。 ويتضمنذلكالتنظيف الدوري لإزالة أي تراكم للمواد التي قد تسد الشاشةوتقللمن كفاءتها。 منالمهمأيضًافحص اللوحةبانتظامبحثًا عنعلاماتالتآكلأو التلف، مثل التمزقات أو الثقوبفيالشبكة، واستبدالهاإذالزم الأمر。 أي تطبيق لنزح المياه، مما يوفر أداءً فائقًا ومتانة。 ومنخلالاتباعإرشادات التثبيت والصيانة المناسبة،يمكن للمستخدمينالتأكدمن أناللوحةتعملبفعالية وتستمرلفترةطويلة。 معالاهتمامالدقيق بالتفاصيلأثناء التركيبوالصيانة المنتظمة، يمكنلهذا المنتج المبتكر أن يعزز بشكلكبيركفاءةعمليات نزح المياه في مختلف الصناعات。

مقارنةالتصميمالجديد للوحةشبكةشاشةنزح المياهمنمادةالبولي يوريثينمعمواد الغربلةالتقليدية

تمثللوحةشبكةشاشةنزح المياهمنمادةالبولي يوريثينذاتالتصميم الجديد تقدمًا كبيرًا في تكنولوجياالغربلة، ==

بالإضافةإلىمتانتها، توفر لوحة شبكة شاشة نزح المياهمنمادةالبولي يوريثينذاتالتصميم الجديد أيضًاكفاءة محسنةفيفصلالمواد الصلبةعنالسوائل。 يسمح التصميمالفريد للوحةبتصريفأكثر فعالية، مما يسهل عملية نزحالمياهبشكلأسرع وتحسينالإنتاجية。 وهذا مفيد بشكل خاص في التطبيقات التي تكون فيهاالمعالجةالسريعة للمواد أمرًابالغ الأهميةللنجاح التشغيلي。 علاوةعلىذلك،فإن تصميماللوحةيقللمن