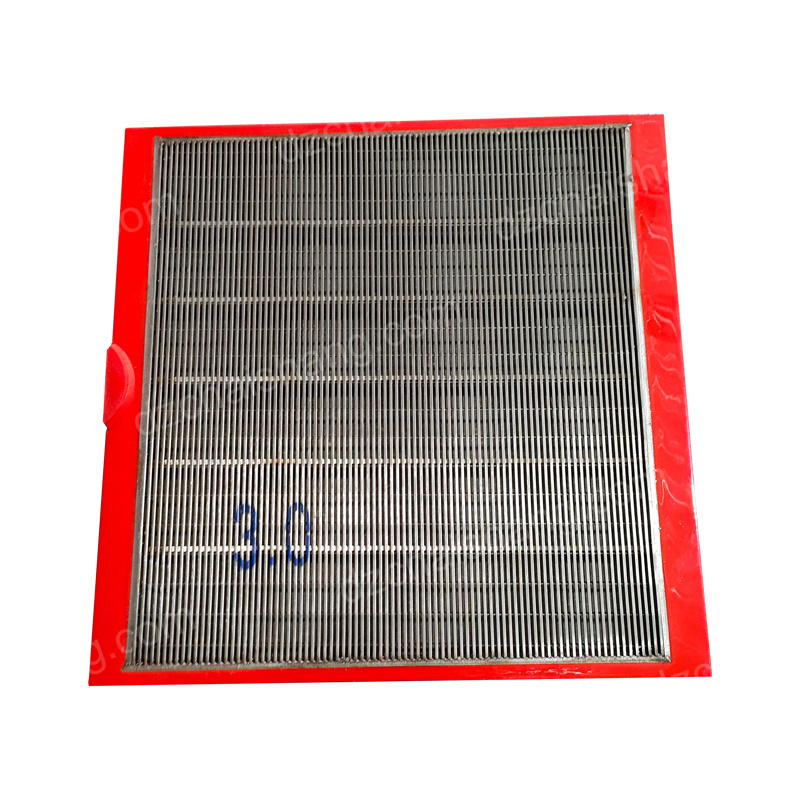

聚氨酯筛网、聚氨酯筛板

استكشافمزايا وتطبيقات شاشات البولي يوريثينوألواحالشاشة

يعد تعدد الاستخدامات ميزةرئيسيةأخرى لشاشات وألواح الشاشة المصنوعةمنمادة البولييوريثين。 وهي متوفرة في مجموعة واسعةمنالأحجام والأشكالوالتكوينات، ممايجعلهامناسبة لمختلفالتطبيقات。 على سبيل المثال، يمكن استخدامهافيعمليات نزح المياه، وسلخ فروة الرأس، والتحجيم، والغسيل。 علاوةعلىذلك،يمكنهم التعاملمعأنواع مختلفةمنالمواد، بدءًامنالركامالخشن وحتىالمساحيقالناعمة。 تسمح هذهالمرونة للشركات بتخصيصحلول الفحصالخاصةبهاوفقًا لاحتياجاتها ومتطلباتهاالمحددة。

تتمتعشاشاتولوحات الشاشةالمصنوعةمن مادةالبولييوريثين بالعديد من التطبيقات عبرمختلفالصناعات。 وفي صناعة التعدين، يتم استخدامهالفصل المعادنالثمينةعن النفايات الصخرية، مما يعززكفاءةعمليات معالجةالمعادن。 وفي صناعة المحاجر، يتم استخدامهالتصنيفوفرز أحجاممختلفةمن الحجارةوالركام،مما يحسنجودةالمنتج النهائي。 فيصناعةإعادة التدوير،يتم استخدامهالفصلالمواد القابلةلإعادة التدوير عن المواد غير القابلةلإعادة التدوير،ممايعزز الاستدامة البيئية。

علاوةعلىذلك، تُستخدم شاشات وألواح الشاشةمنالبولي يوريثينأيضًافيصناعة الأغذيةوالمشروبات。 يتماستخدامهالفصل أحجاممختلفةمنجزيئات الطعام، مما يضمن اتساق وجودةالمنتجالنهائي。 وفي صناعة الأدوية، يتم استخدامهالتصنيفوفرز أحجاممختلفةمن المساحيقالدوائية، ممايعززكفاءةعمليات تصنيعالأدوية。

总而言之,聚氨酯筛网和筛板具有许多优点,包括耐用性、效率和多功能性。它们在不同行业具有广泛的应用,使它们成为需要高质量筛查解决方案的企业的宝贵资产。通过投资聚氨酯筛网和筛板,企业可以提高运营效率,提高产品质量,并最终提高盈利能力。