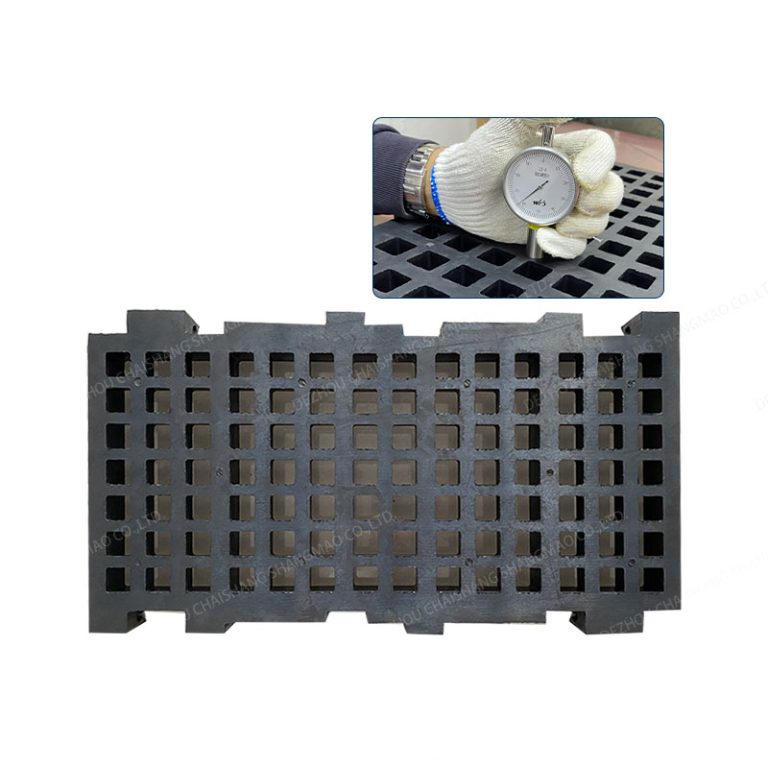

振动筛PU筛网,优质聚氨酯筛网

فوائد وتطبيقات شبكات شاشات البولي يوريثين في الغرابيل الاهتزازية

مزاياشبكاتشاشة البولي يوريثينعالية الجودة لتحسينكفاءة الفحص

**العنوان:شبكةشاشة PUفي الشاشةالاهتزازية: شبكات شاشة من مادة البولي يوريثينعالية الجودة**

إنمرونةشبكاتشاشة البولي يوريثينتساهم أيضًافيفعاليتها。 يمكنتصنيعهذهالشبكات بأشكالوأحجاممختلفة، ومصممةخصيصًا لتطبيقاتأوآلاتمحددة。 لاتضمنهذهالقدرةعلى التكيفالتوافق المثالي الذي يقللمن خطر التجاوز، حيث تمر المواد دون فحصها فحسب، بلتعملأيضًاعلىتحسين الأداءالعاملمعدات الفحص。 تتيح القدرة على تخصيص هذهالشاشاتوفقًا لاحتياجات محددة تحقيق كفاءةالفحصالمثالية، وبالتاليتحسين الإنتاجيةوالكفاءة التشغيلية。 هَم。 تمتصالخصائصالمرنة للبولي يوريثين التأثيرات بشكلأفضلمن الشاشات المعدنية، مما يقللمنالضوضاء الناتجةأثناءعملية الغربلة。 وهذالايساعدفقطفي الامتثالللوائح البيئيةوالسلامةولكن أيضًايحسنظروفالعمل للموظفينالذينيقومون بتشغيل المعدات。

أخيرًا،لا يمكنالتغاضيعن الفوائد الاقتصادية لاستخدامشبكاتشاشة البولي يوريثينعالية الجودة。 في حين أن الاستثمار الأولي في شاشات البولي يوريثينقديكونأعلىمن الشاشات التقليدية، فإن طول العمر وانخفاض احتياجاتالصيانة يوفرانعائدًاأفضلعلى الاستثماربمرورالوقت。 يساهمانخفاضالحاجة إلىعملياتالاستبدال المتكررةوتقليلوقت التوقفعنالصيانةبشكل كبير في توفير التكاليف علىالمدىالطويل。

في الختام، توفرشبكات شاشات البولي يوريثين عاليةالجودةسلسلةمن المزاياالمقنعةالتي تعززكفاءةالفحص وفعاليته。 إنمتانتهاودقتها ومرونتهاوقدراتهاعلى تقليلالضوضاء وفوائدهاالاقتصادية تجعلهاخيارًامتميزًا للصناعات التي تعتمد بشكلكبيرعلىعمليات الفحصالفعالة والموثوقة。 وعلىهذاالنحو،فإن الاستثمارفيهذه المواد المتقدمةلا يؤدي إلى تحسين الجوانب التشغيليةللفحصفحسب، بليساهمأيضًافيزيادة الكفاءةالتنظيمية والإنتاجيةعلىنطاق أوسع.

聚氨酯筛网的主要优点之一是其增强的耐用性。与传统的丝网不同,聚氨酯具有高度的耐磨性,这对于加工材料粗糙且具有磨蚀性的行业尤其有利。这种耐磨性意味着聚氨酯筛网的使用寿命比金属筛网要长得多,从而减少了停机时间和维护成本。此外,聚氨酯的弹性还可以抵抗各种环境因素,如潮湿、紫外线和极端温度,确保在不同操作条件下的性能稳定性。此外,聚氨酯筛网以其卓越的筛分效率而闻名。它们设计有精密开口,比金属丝网能更好地保持均匀性。这一属性至关重要,因为它可以确保一致的粒度分布,这是许多工业过程中的关键因素,其中精确的尺寸至关重要。此外,聚氨酯的光滑表面减少了堵塞和堵塞的机会,特别是在筛选粘性或潮湿材料时,从而在筛选过程中保持高吞吐量。

聚氨酯筛网的灵活性也有助于提高其有效性。这些网格可以制造成各种形状和尺寸,根据特定应用或机械进行定制。这种适应性不仅确保了完美的配合,降低了材料未经筛选就通过的风险,而且还增强了筛选设备的整体性能。能够根据特定需求定制这些筛网,从而实现最佳筛分效率,从而提高生产率和运营效率。

除了其功能优势之外,聚氨酯筛网还有助于降低噪音,这在噪音污染严重的环境中具有显着优势。忧虑。聚氨酯的弹性特性比金属筛网更好地吸收冲击力,减少筛分过程中产生的噪音。这不仅有助于遵守环境和安全法规,还改善了设备操作人员的工作条件。

最后,使用优质聚氨酯筛网的经济效益也不容忽视。虽然聚氨酯筛网的初始投资可能高于传统筛网,但随着时间的推移,较长的使用寿命和减少的维护需求会带来更好的投资回报。从长远来看,频繁更换需求的减少和维护停机时间的减少大大有助于节省成本。

总而言之,高质量的聚氨酯筛网具有一系列引人注目的优势,可提高筛分效率和效果。它们的耐用性、精度、灵活性、降噪能力和经济效益使其成为严重依赖高效可靠筛选过程的行业的最佳选择。因此,投资这些先进材料不仅可以改善筛选的操作方面,还有助于提高更广泛的组织效率和生产力。