What causes material leakage from the edge of the polyurethane screen?

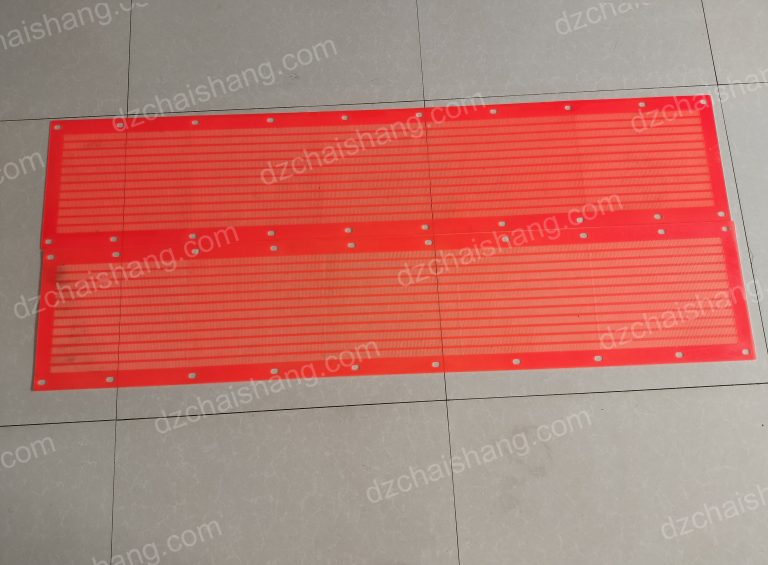

Material leakage from the edges of polyurethane screens is a very serious problem. It may cause the screened materials to be unqualified, and in serious cases it may be re-screened, which will have a great impact on the economic interests and reputation of the company. What is the reason for material leakage from the edge of polyurethane screen?

There are many reasons for polyurethane screen side leakage: one is that the quality of the polyurethane screen is not up to standard, the other is the installation problem of the polyurethane screen, and the third is maintenance problems. Generally speaking, there are no more than three situations.

- Product maintenance

Machines and accessories need to be maintained and inspected after being used for a period of time, otherwise it will malfunction. New polyurethane screens generally have a low failure rate, but after nearly 30 days of use, it is necessary to check whether the materials on the screen have large particles or uneven small particles. If there is any unevenness, please confirm the fixation of the mesh edge and the fastening plate screws within the specified time.

During the screening process, it is necessary to frequently check and listen for abnormal noise problems, and judge and deal with them. On the contrary, if the polyurethane screen is damaged, material leakage will be difficult to deal with.