我如何决定使用哪种尺寸的筛网,中国采石场筛网

فهمالأساسيات:كيفية اختيار الحجمالمناسب لشاشةالشبكة

يعداختيارالشاشة الشبكيةذاتالحجم المناسبلعملية المحاجر في الصين، أو في أي مكان آخر في العالم، قرارًاحاسمًايمكنأن يؤثربشكلكبيرعلى كفاءةوفعاليةالعملية。 يحددحجمالشاشة الشبكيةحجمالمواد التي يمكن أن تمر عبرها، وبالتالي دقةالمنتج النهائي。 ولذلك، فإن فهم أساسيات كيفيةاختيارالشاشة الشبكيةذاتالحجم المناسبأمرضروريلأي عمليةمحجر。

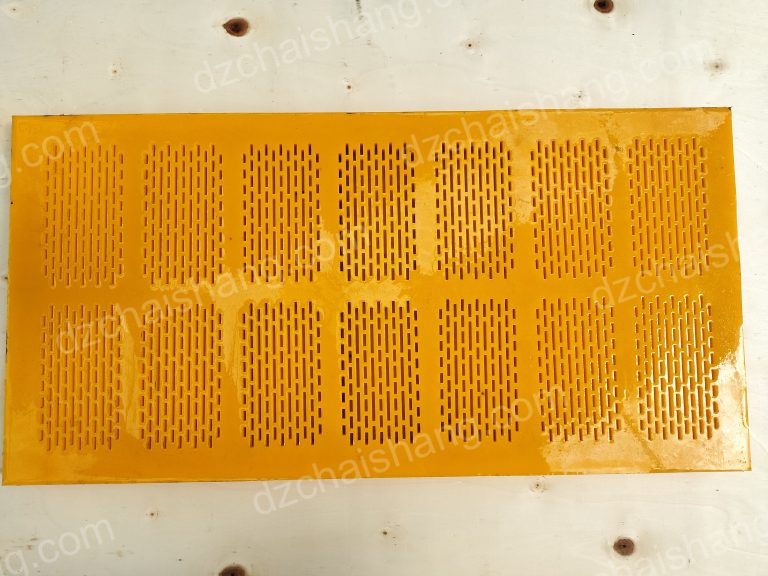

الخطوة الأولىفياختيار الشاشةالشبكيةذات الحجمالمناسبهيفهم مفهومحجمالشبكة。 بعبارات بسيطة، يشير حجم الشبكة إلى عدد الفتحات في كل بوصة في الشاشة。 رقمالشبكةالأعلىيعني فتحات أصغر، وبالتالي، سوف تمر مادة أدق من خلالها。 علىالعكسمنذلك،يشير رقمالشبكةالمنخفضإلى فتحات أكبر، مما يسمح بمرورالموادالأكبر حجمًا。

عند تحديد حجم الشبكة، من المهم مراعاةمتطلباتالمنتج النهائي。 علىسبيلالمثال،إذا كان المنتج النهائي بحاجةإلىأنيكوندقيق الحبيبات، فسيكونرقم الشبكةالأعلىمناسبًا。 منناحيةأخرى،إذاكانت الجسيمات الأكبرحجمًا مقبولة أو حتى مرغوبة، فسيكونرقمالشبكة الأقلأكثرملاءمة.

هناك عاملحاسمآخريجب مراعاتهوهونوعالمادة التييتماستخراجها。 المواد المختلفةلها مستويات صلابة مختلفة، وهذايمكنأنيؤثرعلى اختيارحجمالشبكة。 على سبيل المثال، قد تتطلبالموادالأكثر صلابةحجمًاشبكيًا أكبرلمنعالتآكلغير الضروريعلىالشاشة。 منناحيةأخرى،يمكن معالجةالموادالأكثر ليونةباستخدامشبكة ذات حجم أصغر。

تعدكفاءةعمليةالمحجر أحدالاعتباراتالمهمة الأخرى。 قد يؤدي استخدام حجم شبكةأصغرإلىالحصول على منتج أكثر دقة، ولكنهقديؤديأيضًاإلى إبطاءالعمليةحيث يستغرقمرورالموادعبر الشاشةوقتًاأطول。 لذلك، من الضروري تحقيق التوازنبينجودة المنتج المرغوبة والكفاءةالتشغيلية.

بالإضافةإلىهذه العوامل،منالمهم أيضًامراعاةمتانة الشاشةومتطلبات الصيانة。 تميلالشاشاتذات الأحجامالشبكية الأصغر إلى التآكل بشكل أسرعوتتطلباستبدالًا أكثرتكرارًا،مماقد يؤدي إلى زيادة تكاليف التشغيل。 لذلك، من الضروري اختيار شاشةتوفر التوازنالصحيحبين الأداء والمتانة。

أخيرًا،تجدر الإشارةإلىأنالشركات المصنعةالمختلفةقد تستخدممعاييرمختلفة عند تحديد أحجام الشبكات。 لذلك، من الضروري التأكدمنإجراء المقارنةالمثليةعند اختيارشاشةشبكية。 يعد هذا مهمًا بشكل خاص عند توريد شاشات شبكية من الصين، حيث قد يستخدم المصنعونمعاييرقياس مختلفة。

المحجر، والكفاءة التشغيلية،ومتانة الشاشةومتطلبات الصيانة。 منخلالالنظربعنايةفي هذهالعوامل،يمكن لمشغلي المحاجر اتخاذ قرارمستنيرمنشأنهأن يساعد في ضمان نجاح عملهم.

استكشافشبكة غربلةالمحاجرفيالصين: الميزات والتطبيقات

دليلشامللتحديدحجم الشاشةالشبكية المثالي لاحتياجاتك

يمكنأنيكوناختيار الشاشةالشبكيةذات الحجمالمناسبلعمليات المحاجرالخاصةبكفي الصين مهمة شاقة، خاصة إذا كنت جديدًا في هذه الصناعة。 يمكن أن يؤثر حجم الشاشة الشبكيةالتيتختارها بشكلكبيرعلىكفاءة عملياتك،وجودة مخرجاتك، وفي النهاية، أرباحكالنهائية。 توفرهذهالمقالة دليلاً شاملاً لمساعدتكعلىاتخاذ قرارمستنير。

الخطوةالأولىفيتحديد حجم الشاشة الشبكية المناسبهيفهم احتياجاتكالمحددة。 يلعبنوعالمادةالتي تقوم بمعالجتهادورًا حاسمًا في تحديد حجم الشاشةالمناسب。 علىسبيلالمثال،إذا كنت تتعامل مع مواد خشنة، فإنالشاشة الشبكيةالأكبرحجمًا ستكونمثالية。 منناحيةأخرى،تتطلب المواد الدقيقة شبكات شبكيةأصغرلضمانفصل الجزيئاتبشكل مناسب。

يتمقياسحجم الشاشةالشبكيةبعدد الفتحاتلكلبوصةخطية。 على سبيل المثال، تحتوي الشاشة ذات 4 شبكات على أربعفتحاتفيالبوصة، 100 شبكة على 100 فتحة في البوصة。 كلما زاد رقم الشبكة، كلما كانت الفتحات أصغر وكلماكانت الجسيمات الدقيقةالتييمكنأن تمرعبرها。 لذلك، من الضروري مراعاةحجمالجزيئات التي تريد فصلها عند اختيار حجم الشاشة الشبكية。

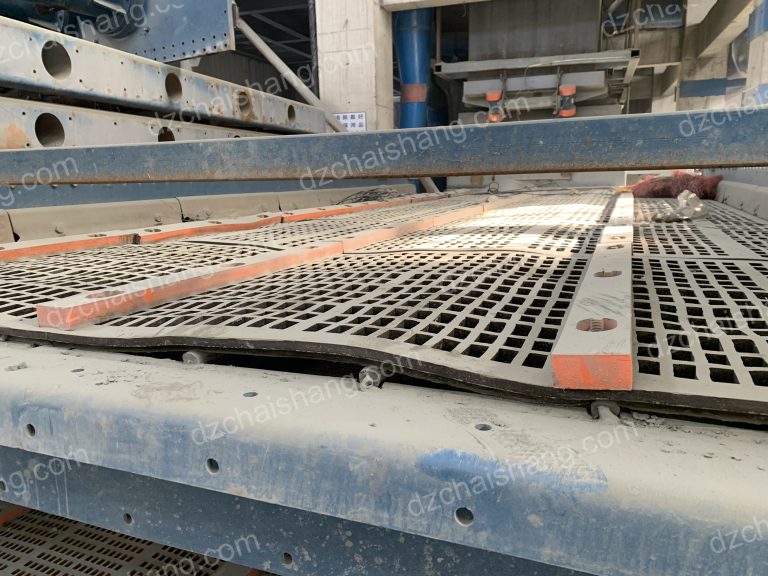

هناكعاملحاسم آخر يجب مراعاته وهو القدرةالإنتاجية للمحجرالخاصبك。 إذاكانتلديكقدرة إنتاجيةعالية،فقد تحتاج إلى شاشة شبكية أكبرللتعاملمعحجم المواد。 ومع ذلك، قد لا تعني الشاشةالأكبر بالضرورةنتائجأفضل。 منالضروريتحقيق التوازنبينحجمالشاشة الشبكيةوحجمالمواد لضمانالكفاءة المثلى。

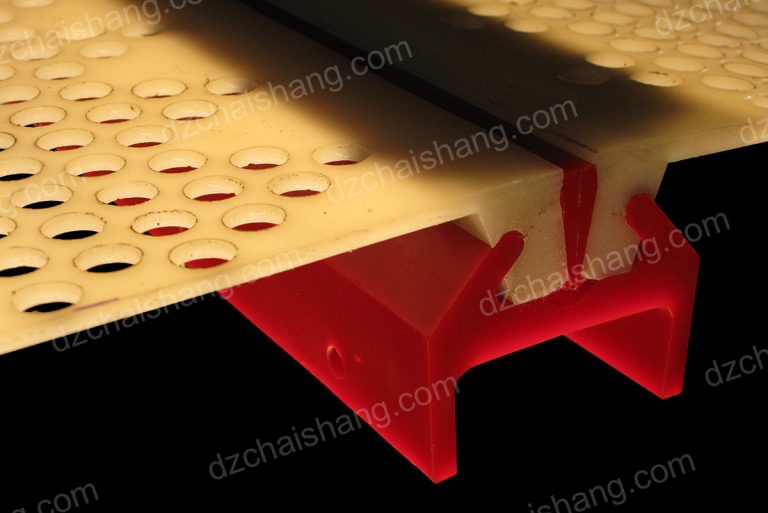

كماتعدمتانة الشاشةالشبكيةأحد الاعتبارات الحيوية أيضًا。 يمكنأنتكونعمليات المحاجرصعبةللغاية، وتتعرضالشاشةالشبكية للكثيرمنالتآكل。 لذلك، من الضروري اختيار شاشة شبكية متينةوقادرةعلىتحمل قسوةعملياتك。 في معظم الحالات، تميل الشاشات المصنوعةمن الفولاذ عالي الشد أو الفولاذ المقاومللصدأ إلىأنتكونأكثرمتانة وتقدمأداءًأفضل。

تعدتكلفةالشاشة الشبكيةعاملًاآخرلا يمكنكالتغاضيعنه。 علىالرغممنأنهقديكون منالمغرياختيار الخيار الأرخص، فمن المهمأنتتذكرأنكتحصل علىماتدفعمقابله。 قدلاتكونالشاشات الشبكيةالرخيصةمتينة وقد لا تقدم النتائج المرجوة。 لذلك، يُنصح بالنظر في القيمةالتيتقدمها الشاشةالشبكيةبدلاً منالسعرفقط。

أخيرًا،منالمهم مراعاةموردالشاشة الشبكية。 لايتمإنشاءجميع الموردينعلىقدم المساواة。 قد يقدم بعض الموردين شاشات شبكية عالية الجودةولكنبأسعار باهظة。 قد يقدم الآخرون شاشات شبكيةرخيصةولكنهم يتنازلونعنالجودة。 لذلك، من الضروري اختيار مورد حسن السمعة يقدم شاشات شبكية عالية الجودةبأسعارمعقولة。

وحجم الجزيئات التي تريد فصلها، وقدرتك الإنتاجية،ومتانة الشاشةالشبكية، والتكلفة،والمورد。 ومنخلالأخذهذه العواملفي الاعتبار، يمكنكاتخاذقرار مستنيرواختيارشاشة شبكية تلبي احتياجاتك الخاصةوتعززكفاءة عملياتك。

网筛的尺寸通过每线性英寸的孔数来测量。例如,4目筛网每英寸有4个开口,而100目筛网每英寸有100个开口。目数越高,开口越小,可以通过的颗粒越细。因此,在选择筛网尺寸时,必须考虑要分离的颗粒的尺寸。

另一个需要考虑的关键因素是采石场的生产能力。如果您的生产能力较高,您可能需要更大的筛网来处理大量的材料。然而,更大的屏幕并不一定意味着更好的结果。在筛网尺寸和材料体积之间取得平衡对于确保最佳效率至关重要。

筛网的耐用性也是一个重要的考虑因素。采石场作业要求相当高,筛网会遭受大量磨损。因此,选择耐用且能够承受严酷操作的筛网至关重要。在大多数情况下,由高强度钢或不锈钢制成的筛网往往更耐用且性能更好。

网筛的成本是另一个不容忽视的因素。虽然选择最便宜的选择可能很诱人,但重要的是要记住一分钱一分货。廉价的网筛可能不耐用,并且可能无法达到预期的效果。因此,建议考虑筛网提供的价值而不仅仅是价格。

最后,重要的是要考虑筛网的供应商。并非所有供应商都是生来平等的。一些供应商可能提供高质量的网筛,但价格过高。其他人可能会提供廉价的网筛,但质量会受到影响。因此,选择一家以合理价格提供高质量筛网的信誉良好的供应商至关重要。总之,为您在中国的采石场作业选择合适尺寸的筛网需要考虑多种因素,包括您正在加工的材料类型,您想要分离的颗粒大小,您的生产能力,筛网的耐用性,成本和供应商。通过考虑这些因素,您可以做出明智的决定并选择满足您的特定需求并提高运营效率的网筛。