mining polyurethane screen, metal mesh

= .. عمليات التعدين

= المعدنيةوشاشات .. تطبيقات التعدين

= الشبكات المعدنية = بمجموعةخاصةبهامن المزاياوالعيوبفي تطبيقاتالتعدين。 ت… .. وقوتها، في حين توو .. المرونةومقاومة التآكل。 عندالاختياربين الخيارين، يجبعلى .. ف&u064a كفاءةالفحص،ومتط”Ʉ الصيانة،وقيود الميزانيةوفي المطاف، ” علىالاحتياجات = لعمليةالتعدين。

总而言之,金属网和聚氨酯筛网在ज 7矿应用中都有各自的优点和缺点。झ 1属网筛以其耐用性和强度而闻名,ࠀ c聚氨酯筛网则具有灵活性和耐磨性。 在这两种方案之间进行选择时,矿业 公司应考虑筛选效率、维护要求和预 算限制等因素。最终,最佳选择将取 决于采矿作业的具体需求和优先级。

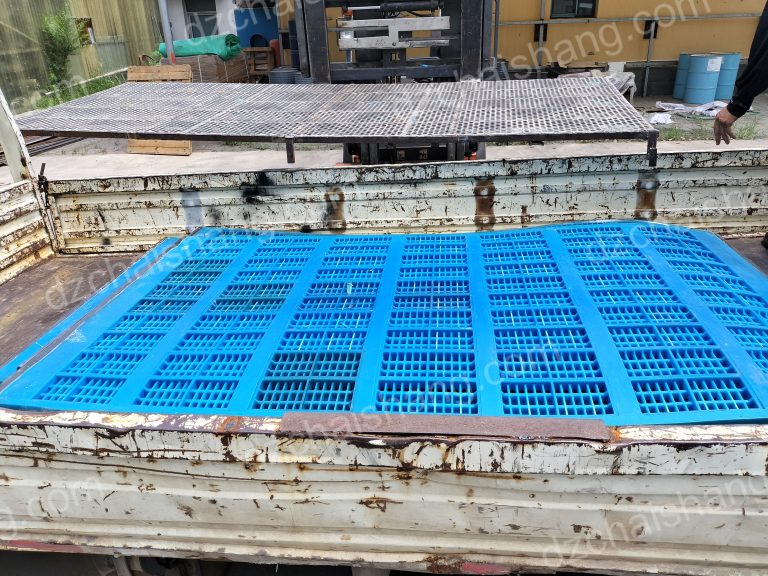

在采矿业中,筛分材料的选择对于确保高效和有效的运营至关重要。筛分材料的两种常见选择是金属网和聚氨酯筛网。两者都有各自的优点和缺点,因此采矿公司必须仔细考虑哪种选择最适合其特定需求。金属网筛多年来一直是采矿业的传统选择。它们以其耐用性和强度而闻名,非常适合重型应用。金属网筛通常由不锈钢或高碳钢制成,这使得它们能够承受采矿作业的恶劣条件。这些筛网还以其高拉伸强度而闻名,这有助于防止它们快速破裂或磨损。

但是,金属网筛网也有一些缺点。金属网筛的主要缺点之一是它们容易被细颗粒堵塞。这可能会导致筛选效率降低并增加清洁和维护的停机时间。此外,金属网筛在操作过程中可能会产生噪音,这可能是采矿环境中工人所关心的问题。

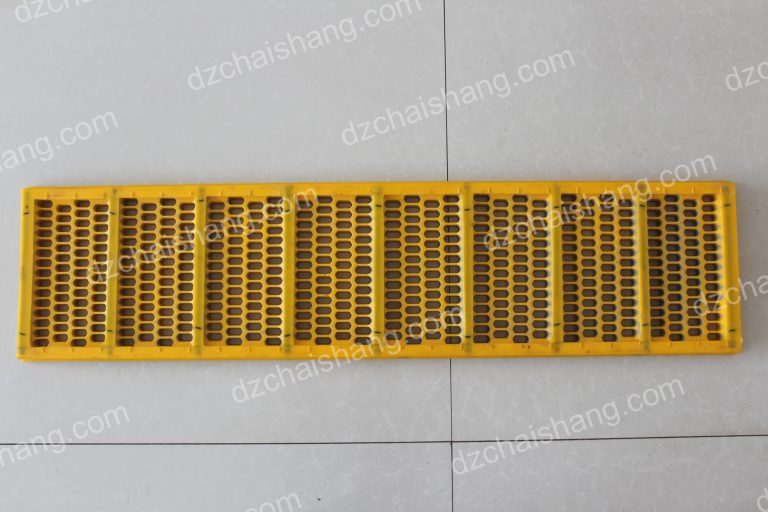

另一方面,聚氨酯筛网作为金属网筛的替代品近年来变得越来越流行。聚氨酯筛网以其柔韧性和耐磨性而闻名,使其成为需要高耐磨性的筛分应用的理想选择。这些筛网重量轻,有助于降低设备整体重量和能耗。

聚氨酯筛网的主要优点之一是能够减少堵塞和堵塞。聚氨酯的柔韧性可以更好地筛选细颗粒,从而提高筛选效率。与金属网筛网相比,聚氨酯筛网在运行过程中也更安静,为矿工创造了更舒适的工作环境。

尽管聚氨酯筛网有优点,但也有一些缺点。与金属网筛相比,聚氨酯筛网的主要问题之一是其拉伸强度较低。这可能会导致聚氨酯筛网的使用寿命缩短,特别是在高影响应用中。此外,与金属网筛相比,聚氨酯筛网的前期成本可能更高,这对于预算有限的矿业公司来说可能是一个考虑因素。

总而言之,金属网和聚氨酯筛网在采矿应用中都有各自的优点和缺点。金属网筛以其耐用性和强度而闻名,而聚氨酯筛网则具有灵活性和耐磨性。在这两种方案之间进行选择时,矿业公司应考虑筛选效率、维护要求和预算限制等因素。最终,最佳选择将取决于采矿作业的具体需求和优先级。