polyurethane dewatering screens

The Benefits of Using polyurethane Dewatering screens in Industrial Applications

Polyurethane dewatering screens have become increasingly popular in industrial applications due to their numerous benefits. These screens are made from a durable and flexible material that offers several advantages over traditional screens. In this article, we will explore the benefits of using polyurethane dewatering screens in industrial applications.

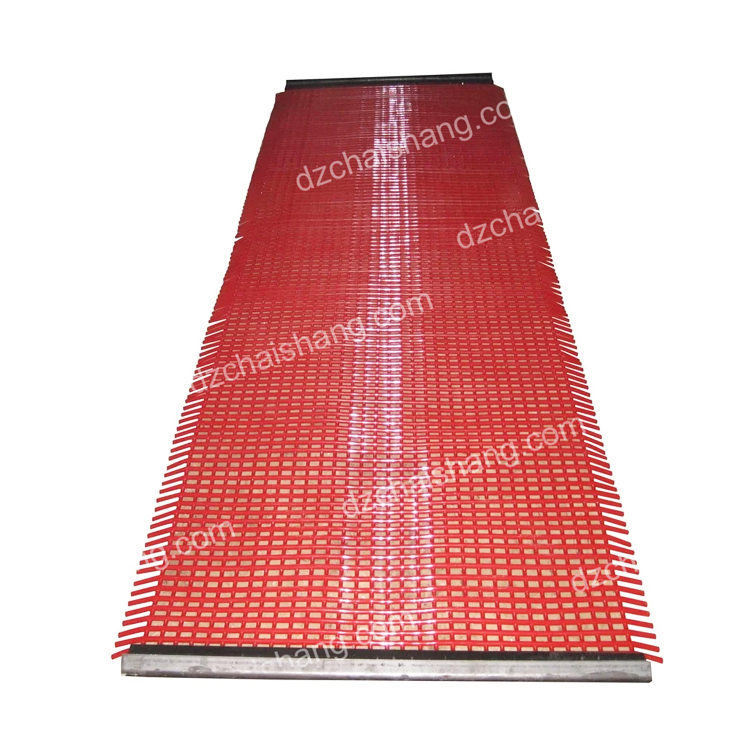

One of the main advantages of polyurethane dewatering screens is their high abrasion resistance. Industrial processes often involve the handling of abrasive materials, which can quickly wear down traditional screens. However, polyurethane screens are designed to withstand the harsh conditions of industrial environments, ensuring a longer lifespan and reduced maintenance costs.

In addition to their durability, polyurethane dewatering screens also offer excellent chemical resistance. Many industrial processes involve the use of chemicals that can corrode or degrade traditional screens. Polyurethane, on the other hand, is highly resistant to a wide range of chemicals, making it an ideal choice for industries that deal with corrosive substances.

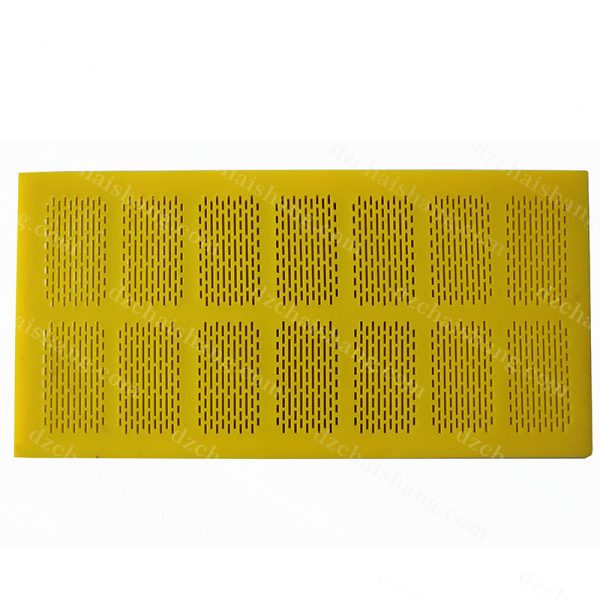

Another benefit of polyurethane dewatering screens is their flexibility. Unlike rigid screens, polyurethane screens can be easily molded into various shapes and sizes to fit specific industrial applications. This flexibility allows for greater customization and ensures a perfect fit for each unique process.

Polyurethane screens also have superior vibration absorption properties. Industrial machinery often generates significant vibrations, which can impact the performance and lifespan of traditional screens. However, polyurethane screens effectively absorb these vibrations, reducing the risk of damage and improving overall efficiency.

Furthermore, polyurethane dewatering screens offer excellent moisture resistance. In many industrial applications, moisture can be a significant concern, as it can lead to screen clogging and reduced productivity. Polyurethane screens are designed to repel moisture, ensuring optimal performance even in wet conditions.

In terms of efficiency, polyurethane dewatering screens excel at dewatering and separating materials. These screens have a unique design that allows for efficient drainage and removal of water from various materials. This is particularly beneficial in industries such as mining and aggregate processing, where the separation of water from solids is crucial.

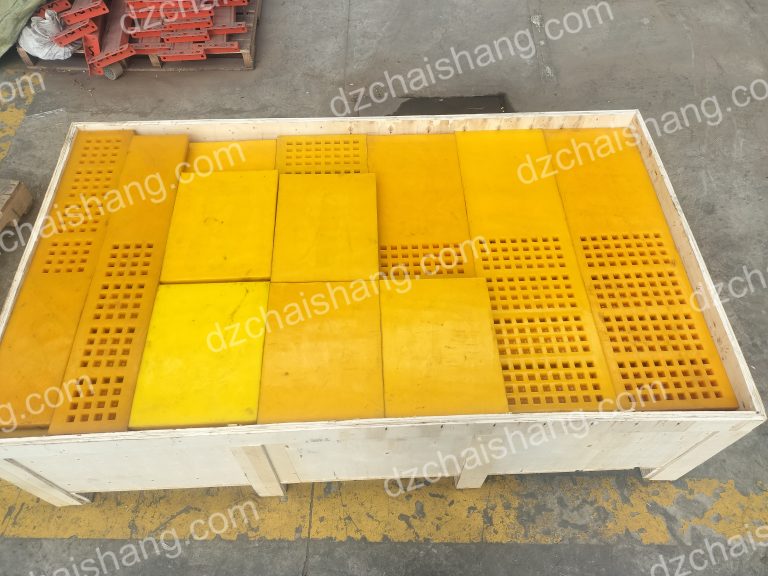

Additionally, polyurethane screens are easy to install and maintain. Their lightweight nature makes them easy to handle and install, reducing downtime during the installation process. Moreover, their self-cleaning properties minimize the need for regular maintenance, saving both time and money for industrial operators.

Lastly, polyurethane dewatering screens are environmentally friendly. They are made from a recyclable material that can be reused or repurposed, reducing waste and contributing to a more sustainable industrial sector. This eco-friendly aspect is increasingly important in today’s world, where businesses are striving to minimize their environmental impact.

In conclusion, polyurethane dewatering screens offer numerous benefits for industrial applications. Their high abrasion resistance, chemical resistance, flexibility, vibration absorption properties, moisture resistance, and efficiency make them an excellent choice for various industries. Additionally, their easy installation and maintenance, as well as their eco-friendly nature, further enhance their appeal. As industries continue to seek more efficient and sustainable solutions, polyurethane dewatering screens are likely to become even more prevalent in the industrial sector.