聚氨酯振动筛网

فوائداستخدامشبكة الغربالالاهتزازيةمن مادةالبولييوريثينفي عمليات التعدين

نصائح لصيانة شبكة الغربلةالاهتزازيةمن مادةالبولييوريثين

تُستخدمشبكةالغربلة الاهتزازيةمنمادة البولي يوريثينعلى نطاقواسعفيمختلف الصناعات لمتانتها وكفاءتهاوقدرتهاعلى تقليلالضوضاء واستهلاكالطاقة。 هذاالنوعمنشبكات الغربلةمصنوعمنمادة البولي يوريثينذات الجودةالعالية، والمعروفةبقوةالشد العاليةوالمرونة。 إنه مكون أساسي في آلات الفحصالمستخدمةفي التعدينواستغلال المحاجروالتطبيقات الصناعيةالأخرى。 لضمانالأداءالأمثل وطولالعمرلشبكة الغربلةالاهتزازيةمن مادة البولي يوريثين، تعدالصيانةالمناسبة أمرًابالغ الأهمية。

إحدىنصائح الصيانةالأساسية لشبكةالغربلة الاهتزازيةمنمادة البولي يوريثينهي الفحصالمنتظم。 منالمهمفحصالشبكة بحثًاعنأيعلاماتتآكل أوتلف،مثلالتمزقاتأو الثقوبأوالسحجات。 الكشفالمبكرعنهذه المشكلاتيمكنأنيمنع المزيدمنالتدهور والفشلالمحتملللشبكة。 أثناءالفحص،من الضروري أيضًا فحص شد الشبكة。 يعد التوتر المناسب أمرًابالغالأهمية للفحصالفعالويمكنأن يساعد في منع الشبكة من الترهلأوالارتخاء。

يعدتنظيفشبكةالغربال الاهتزازيةمنمادة البولي يوريثينممارسة صيانةحيويةأخرى。 معمرورالوقت،يمكنأن يتراكمالغبار والأوساخ وغيرهامن الحطام في الشبكة، مما قد يسد الفتحات ويقلل من كفاءةالفحص。 لتنظيفالشبكة،يوصى باستخدامفرشاةناعمة أورذاذماءمنخفضالضغط。 تجنباستخدامالمواد الكيميائيةالقاسيةأو المواد الكاشطة، لأنها يمكنأنتلحقالضرر بمادةالبولييوريثين。 بعد التنظيف، تأكد من أن الشبكةجافةتمامًاقبل إعادةتثبيتهافيآلة الغربلة。

بالإضافةإلىالفحص والتنظيفالمنتظم،من المهمالتعاملمعشبكة الغربلةالاهتزازية المصنوعةمنمادة البولي يوريثينبعناية أثناءالتثبيت والإزالة。 يجبتركيبالشبكةوفقًا لتعليماتالشركة المصنعةلضمان الملاءمةوالشد المناسبين。 عند إزالة الشبكة، تجنب استخدامالأدوات الحادة التي قد تؤدي إلى قطعالمادةأوثقبها。 بدلاً من ذلك، استخدم معدات وتقنيات الرفع المناسبةلمنعتلف الشبكة。

نصيحةصيانة أخرىلشبكةالغربلة الاهتزازيةمنمادة البولي يوريثينهي مراقبة ظروف تشغيل آلة الغربلة。 يمكنأنيساهمالاهتزاز المفرطودرجةالحرارة المرتفعةوالتعرض للمواد المسببةللتآكل فيالتآكلالمبكر للشبكة。 منالمهمالتأكدمنأن الماكينةتعملضمن المعلمات الموصىبها وإجراءأيتعديلات ضروريةلمنعتلفالشبكة。

أخيرًا،يُنصح بالاحتفاظبسجللأنشطة الصيانةالتييتم إجراؤهاعلىشبكة الغربلةالاهتزازية المصنوعةمنمادة البولييوريثين。 يمكنأنيتضمنهذاالسجل تفاصيل مثل تاريخ الفحص والتنظيفوالاستبدال، بالإضافةإلىأيمشكلات تمت ملاحظتها والإجراءات التصحيحية المتخذة。 يمكن أن يساعد الاحتفاظ بسجلالصيانةفيتتبع أداءالشبكةبمرور الوقت وتحديد أي مشكلات متكررة قد تحتاج إلى مزيدمنالاهتمام。 يعد الفحصالمنتظم والتنظيفوالتعامل الدقيقومراقبةظروف التشغيلوحفظالسجلات كلهاممارساتمهمةيمكن أنتساعدفيالحفاظعلى سلامةالشبكةوكفاءتها。 منخلالاتباعنصائح الصيانةهذه،يمكن للمستخدمينتعظيم فوائد شبكة الغربلة الاهتزازيةمنمادة البولي يوريثينفي تطبيقاتهم الصناعية.

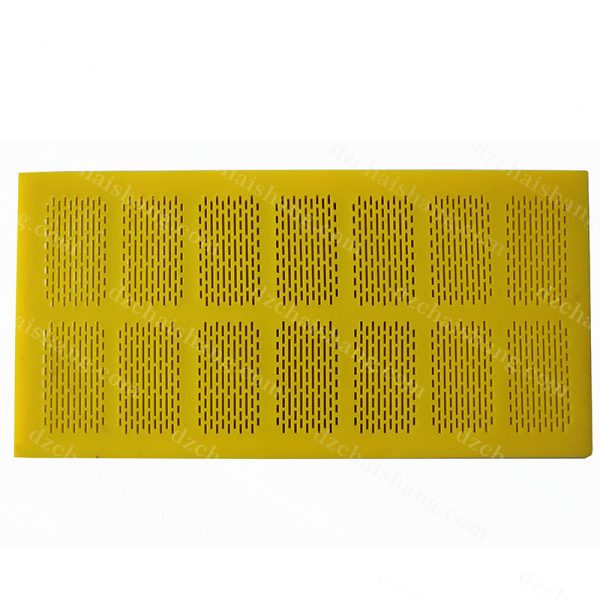

شبكةالغربلة الاهتزازيةمنمادة البولي يوريثين

تعد شبكات الغربلة الاهتزازيةمكونات أساسيةفيصناعات التعدينوالتجميع، وتستخدملفرزالمواد المختلفةوفصلها وتغييرحجمهاوتصفيتها。 منبينالموادالمختلفة المستخدمةلتصنيعهذه الشبكات، يعتبر البولي يوريثينوالمطاطمن أكثرالموادشعبيةبسبب متانتهاوفعاليتها。 ومع ذلك، فإن كل مادة توفرمزاياوعيوب مميزة، مما يجعلها مناسبةلتطبيقات مختلفة。

شبكةالغربال الاهتزازيةمنالبولي يوريثينمفضلةللغاية لمتانتهاالاستثنائية ومقاومتهاالعالية للتآكلوالتمزق。 تُعرفهذهالمادة الاصطناعيةبقدرتها علىتحملالظروف البيئيةالقاسية،بما فيذلكالتعرضللزيوت والمذيبات ودرجات الحرارةالقصوى。 نتيجة لذلك، تعتبر شبكة البولي يوريثينخيارًا ممتازًالفحصالمواد الكاشطةمثلالرمل والحصىوالأحجار المكسرة。 لاتضمنمرونتهعمرًا أطولفحسب،بلتقلل أيضًامنتكاليف الصيانة، حيث لا تتطلب عمليات استبدال متكررة.

علاوةعلىذلك، يتميزالبولييوريثين بمرونةعالية،ممايسمح لهبامتصاصالصدمات بشكلأفضلمنالمواد الأخرى。 تساعدهذهالمرونةعلى تقليلفرصالتعمية والربط، وهي مشكلات شائعة تحدث عندما تتعثر الجزيئات في فتحات الشبكة。 ومنخلالتقليلهذه الأحداث،تعملشبكة البولي يوريثينعلى تعزيزكفاءةالفحص وتضمن إنتاج منتج أكثر اتساقًا。 بالإضافةإلىذلك،فإن السطح الأملسللبولي يوريثينيقلل الاحتكاك، ممايساهم أيضًافيأدائهالمتفوق فيتطبيقاتالفحص。 。 هذهالمادةفعالةبشكل خاصفيتخفيفالضوضاء، ممايجعلهامثالية للاستخدامفيالمناطق الحضريةأوالسكنيةحيث يمكنأنيكونالتلوث الضوضائيمصدرقلق。 المطاطأيضًامقاوم للغايةللتآكلويوفر مرونةجيدة،ممايساعد فيامتصاصالصدمات وتقليلالتآكل。

ومع ذلك، قد لا يكون المطاطمتينًامثلمادة البولي يوريثينعند تعرضهلبعضالمواد الكيميائيةودرجات الحرارةالمرتفعة。 يمكنأنتتحللبسرعة أكبر، مما يؤدي إلى عمر خدمةأقصروزيادة تكاليفالاستبدال。 بالإضافةإلىذلك،قد يكونالسطحالناعم للمطاطأكثرعرضة للتمزقوالتمزقعند التعاملمعالمواد الخشنة، مما قد يؤثر على كفاءةعملية الغربلة。

عندمقارنة شبكات الغربال الاهتزازيةالمصنوعة من مادة البولي يوريثين والمطاط، من الضروري مراعاةالمتطلبات المحددةللتطبيق 。 بالنسبةللبيئاتالتي تحتوي على مواد كاشطة ودرجات حرارةعالية، يعد البولي يوريثين بشكلعامالخيارالأفضل نظرًالقوتهوطولعمره。 يمكن أن تؤدي قدرتها على الحفاظعلىالأداءفيظل الظروفالصعبةإلى توفير كبير في التكاليف بمرورالوقت.

علىالعكس منذلك،بالنسبة للتطبيقات التي يكون فيهاتقليلالضوضاء أولوية، أو حيث لا تكون المادةالتيتتم معالجتهاكاشطةبشكل خاص، قد تكون شبكة الغربلةالمطاطية الاهتزازيةهيالأكثر ملاءمةخيار。 إنخصائصهاالمخففة للضوضاءوالمقاومة الجيدةللتأثيرات تجعلهامناسبةلمثلهذه السيناريوهات。 يجبأنيعتمدالاختيار بينالمادتينعلىعوامل مثلنوعالموادالتيتتم معالجتها، والظروف البيئية،ومتطلبات التشغيلالمحددة。 منخلالتقييمهذه الجوانببعناية،يمكن لمحترفيالصناعة اختيار شبكة الغربلة الاهتزازيةالأكثر ملاءمةوالتيستوفر الأداءالأمثلوفعالية التكلفة。

但是,当暴露于某些化学品和高温时,橡胶可能不如聚氨酯耐用。它会更快地降解,导致使用寿命缩短并增加更换成本。此外,在处理粗糙材料时,橡胶较软的表面可能更容易撕裂和撕裂,这可能会影响筛选过程的效率。

在比较聚氨酯和橡胶振动筛网时,考虑应用的具体要求至关重要。对于涉及磨料和高温的环境,聚氨酯由于其坚固性和使用寿命通常是最佳选择。它能够在具有挑战性的条件下保持性能,随着时间的推移,可以显着节省成本。

相反,对于优先考虑降噪或所处理的材料不是特别耐磨的应用,橡胶振动筛网可能更合适选项。其隔音性能和良好的抗冲击性使其适合此类场景。

总而言之,聚氨酯和橡胶振动筛网都具有独特的优点,使其适用于不同的筛分应用。两种材料之间的选择应基于所加工材料的类型、环境条件和具体操作要求等因素。通过仔细评估这些方面,行业专业人士可以选择最合适的振动筛网,以提供最佳的性能和成本效益。