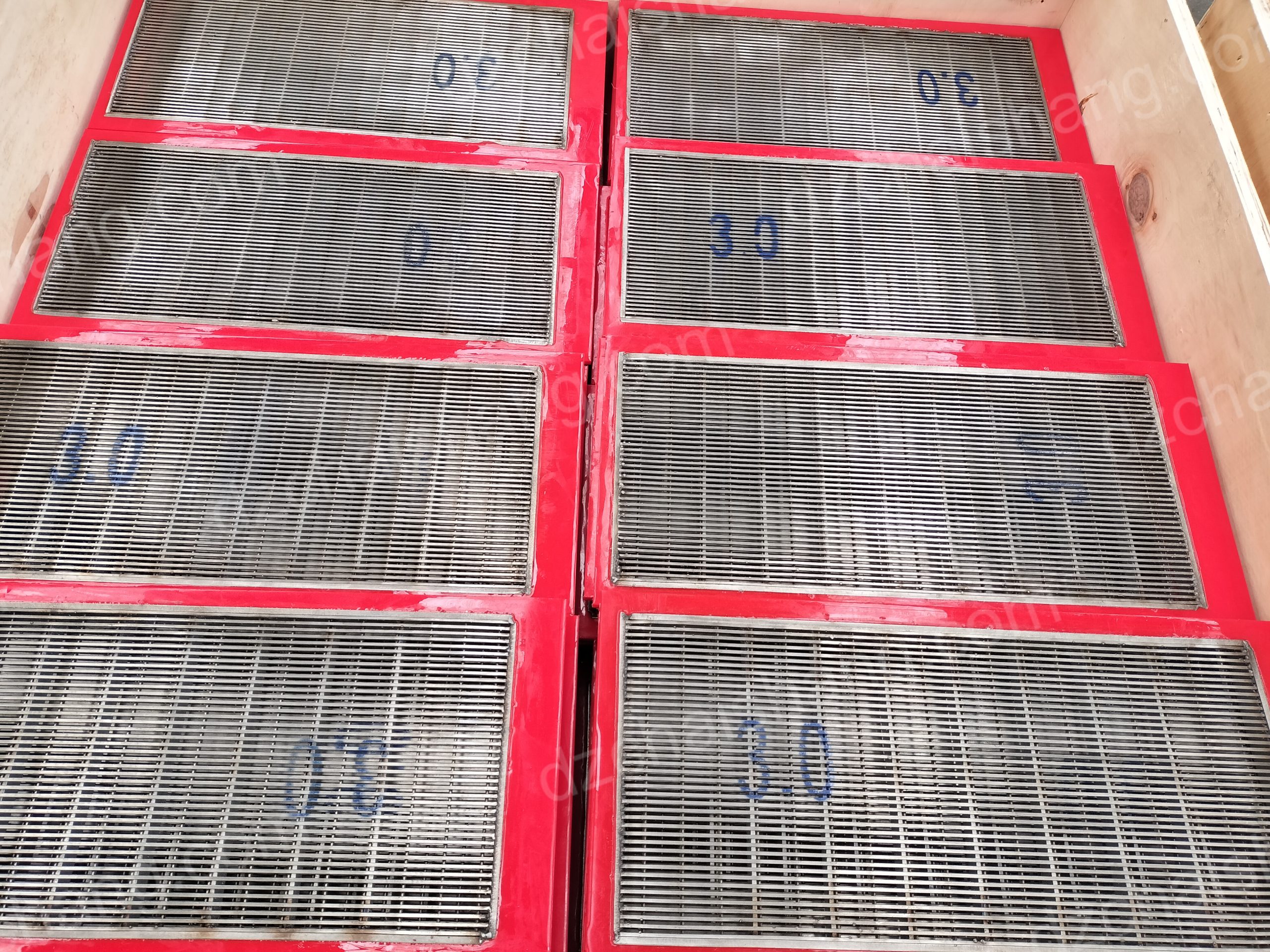

PU筛网脱水筛、网板

فوائداستخدامشبكة شاشة PU في شاشات نزح المياه

تعد شبكة شاشة البولي يوريثين(PU)خيارًاشائعًا لشاشات نزح المياه نظرًالفوائدها ومزاياهاالعديدة。 تُستخدمشاشاتنزح المياهفيصناعات مختلفة لفصل الجزيئات الصلبةعنالسوائل، ويمكنأنيؤدياستخدام شبكة غربال PU إلى تعزيز كفاءةوفعاليةهذه العمليةبشكلكبير.

إحدى الفوائدالرئيسية لاستخدام شبكة غربال PU في شاشات نزح المياه هي متانتها。 。 PUعبارةعنمادةمتينة للغايةيمكنهاتحمل ظروف التشغيلالقاسية والأحمالالثقيلة。 وهذايعنيأنشبكة الشاشة PU يمكن أن تستمر لفترةأطولوتتطلب استبدالًاأقلتكرارًا مقارنةبالأنواع الأخرىمنشبكات الشاشة، مما يوفر الوقت والمالعلىالمدى الطويل。

بالإضافةإلى متانتها،فإنشبكة الشاشة PU أيضًامقاومة للغايةللتآكلويرتدي。 وهذايعنيأنهيمكنه الحفاظعلىسلامته وأدائهحتىعندتعرضه لمستوياتعاليةمن التآكل。 تعدهذهالمقاومة للتآكلمهمةبشكلخاصفي شاشات نزح المياه، حيث يمكنأنتتسببالحركة المستمرةللجزيئات الصلبة ضد شبكة الشاشة في تآكل كبير بمرور الوقت.

علاوةعلىذلك، تتميز شبكة شاشة PU بمرونة عاليةويمكنتشكيلها بسهولةلتناسب المتطلبات المحددةلـ شاشات نزح المياه المختلفة。 وتسمح هذه المرونة بقدر أكبرمنالتخصيص والتحسينلشبكة الشاشة، مما يؤدي إلى تحسينالأداءوالكفاءة。 بالإضافةإلىذلك، تتوفر شبكة شاشة PU في مجموعةواسعةمنأحجام وتكوينات الفتحة، مما يجعلهامناسبةلمجموعة متنوعة منالتطبيقات وأحجامالجسيمات。

ميزة أخرىلاستخدامشبكة شاشة PU في شاشات نزح المياههيقدراتها الممتازةعلىنزح المياه。 PU للسماح بالتصريف الفعالونزحالماءمن الجزيئات الصلبة، مما يؤدي إلى جودة أعلى للموادالسائلة والصلبةالمنفصلة。 يمكن أن يؤدي أداء نزح المياهالمحسنهذاإلى زيادةالإنتاجية والإنتاجيةفيعمليات نزح المياه.

علاوةعلى ذلك، شبكة منخل PU سهلة التنظيفوالصيانة،مما يجعلهاخيارًامناسبًا لمشغليمنخلنزحالمياه。 يمنع السطح الأملس لشبكة شاشة PU تراكم المواد والحطام، مما يقللالحاجةإلى التنظيفوالصيانة المتكررة。 هذالايوفرالوقت والجهد فحسب، بل يضمن أيضًاالأداءالمتسق والكفاءةلغربلةنزح المياه。

في الختام، فوائد استخدام شبكة منخل PU في مناخل نزح المياهواضحة。 إنمتانتهومقاومته للتآكلومرونته وإمكانيات نزح المياه وسهولةالصيانةتجعله خيارًامثاليًا لمجموعةواسعةمن تطبيقاتنزحالمياه。 منخلالالاستثمارفي شبكةغربال PU،يمكن للمشغلينتحسينأداء وكفاءةشاشاتنزح المياهالخاصةبهم،مما يؤدي إلى زيادة الإنتاجيةوتوفير التكاليفعلىالمدى الطويل。

إنشاشاتنزحالمياه الشبكيةمنالبولي يوريثانهيمعدات أساسيةفيمختلف الصناعات، بما في ذلك التعدينوالبناء والزراعة。 تلعبهذهالشاشاتدورًا حاسمًافيفصلالمواد الصلبةعنالسوائل،مما يضمنكفاءةوفعالية العمليات。 للحفاظعلىأداءوطول عمر شاشات نزح المياه من شبكة شاشة PU، تعد الصيانة والتنظيفالمناسبين أمرًاضروريًا。

أحدالجوانبالرئيسية لصيانةشاشاتنزح المياهمنشبكةشاشة PUهو الفحصالمنتظم。 يتيح لك فحص الشاشات تحديد أي علامات تآكل، مثلالثقوبأوالتمزقات أوالتمدد。 منخلالاكتشافهذه المشكلات مبكرًا، يمكنكمنعالمزيدمن الضرروالتأكدمن استمرارالشاشاتفي العملعلىالنحو الأمثل。

بالإضافةإلى عمليات الفحص المنتظمة، يعد تنظيف شاشات نزح المياه من شبكة PUأمرًابالغ الأهميةأيضًا。 معمرورالوقت،يمكنأن تصبح الشاشات مسدودة بالحطام،ممايقللمن كفاءتها。 لتنظيفالشاشات،ابدأ بإزالتهامنالمعدات وشطفهابالماء。 استخدمفرشاةناعمةأو قطعةقماشلفركأي تراكمات بلطف، مع الحرص علىعدمإتلافالشبكة.

للحصولعلىالمزيدمن الحطام العنيد، يمكنك استخداممنظفمعتدلأو محلولتنظيف。 تجنباستخدامالمواد الكيميائيةالقاسيةأو المواد الكاشطة، لأنها يمكنأنتلحقالضرر بشبكةشاشة PU。 بمجردتنظيفالشاشات، اشطفهاجيدًابالماء لإزالة أي بقايا。

بعد تنظيفالشاشات،اتركها حتى تجف تمامًا قبل إعادةتركيبها。 يعدالتجفيفالمناسب أمرًاضروريًالمنعنمو العفنأوالفطريات،مما قديضربسلامةالشاشات。 بمجرد أن تجف، قم بفحص الشاشات مرة أخرى للتأكدمنخلوهامنأي حطامأوتلف متبقي。

بالإضافةإلى التنظيفالمنتظم،من المهمتخزينشاشاتنزح المياهمنشبكة PU بشكل صحيح عندما لا تكون قيد الاستخدام。 قمبتخزينالشاشاتفي منطقةنظيفةوجافة بعيدًاعنأشعةالشمس المباشرةودرجات الحرارةالقصوى。 تجنبتكديسالشاشاتأو طيها، لأن ذلك قد يتسبب في تلف الشبكة。

عندالتعاملمعشاشات نزح المياه من شبكة PU، كن لطيفًالتجنبتمديد الشبكةأوتمزيقها。 توخي الحذر عند تثبيت أو إزالةالشاشاتمن المعدات،واتبع إرشادات الشركة المصنعةللتعامل السليم。

في الختام، تعد الصيانة والتنظيفالمناسبين ضروريينلضمانطولعمر وأداء شاشات نزح المياه منشبكةشاشة PU。 منخلالفحصالشاشات وتنظيفهاوتخزينها بشكلصحيحبشكلمنتظم، يمكنكمنعالضرر والتأكد من استمرارها فيالعملبفعالية。 تذكرالتعاملمع الشاشات بعنايةواتباع إرشادات الشركة المصنعةللحصولعلى أفضلالنتائج。 معالصيانةالمناسبة، يمكن لشاشات نزح المياه الشبكية PU أن توفر سنوات منالخدمةالموثوقةفي مجموعةمتنوعةمن الصناعات。

مقارنةشبكةغربال PU مقابلالأنواعالأخرى منالألواحالشبكية لشاشات نزح المياه

عندمايتعلقالأمر بشاشات نزح المياه، يعد اختيار شبكة الشاشة أمرًابالغالأهميةفي تحديدكفاءةوفعالية عمليةنزحالمياه。 أحدالخياراتالشائعة لشبكةالشاشةهوشبكة الشاشة PU، والتي توفر العديدمنالمزايا مقارنةبالأنواع الأخرىمنالألواح الشبكية。 في هذه المقالة، سنقوم بمقارنةشبكةشاشة PUمع أنواعأخرىمنالألواح الشبكيةالمستخدمة بشكل شائع في شاشات نزح المياه.

شبكةشاشة PU، المعروفةأيضًاباسم شبكةشاشةالبولي يوريثين،هينوعمن شبكات الشاشةالمصنوعة منمادةالبولييوريثين。 وهي معروفة بمقاومتها العاليةللتآكل ومقاومةالتآكل والمتانة。 تتميزشبكةغربال البولي يوريثانأيضًا بالمرونةويمكن تشكيلهابسهولةفي أشكالوأحجاممختلفة، ممايجعلهامناسبة لمختلف تطبيقات نزح المياه.

بالمقارنة،فإن الأنواعالأخرىمن الألواح الشبكية، مثل ألواح الشبكات الفولاذيةأوألواح الشبكات المطاطية، لها مجموعتهاالخاصةمن المزاياوالعيوب。 تُعرف الألواح الشبكية الفولاذيةبقوتها وصلابتها، مما يجعلها مناسبةللتطبيقات الثقيلة。 ومع ذلك، فإن الألواح الشبكيةالفولاذية عرضةللتآكلوالتآكل، مماقديؤثرعلىطول عمرهاوأدائهابمرور الوقت。

منناحيةأخرى،فإن الألواح الشبكية المطاطيةمعروفة بمرونتهاومرونتها。 يمكنأنتتوافقبسهولة مع شكل شاشة نزح المياه، ممايوفرإغلاقًا محكمًاويمنعالموادمن الهروب。 ومع ذلك، قد لا تكون الألواحالشبكية المطاطيةمتينةمثل شبكة شاشة PU وقد تتطلب استبدالًاأكثر تكرارًا。

واحدةمنالمزايا الرئيسيةلشبكةشاشة PUهي مقاومتهاالعالية للتآكل。 يمكن لشبكة شاشة PU أن تتحملالتأثيرات الكاشطةللموادالتي تتممعالجتها،مثل الرمل، الحصى، أوالفحم。 PU مثالية للتطبيقات التي تتطلبمقاومةعالية للتآكل، كما هو الحال في التعدينأوالمحاجرأو البناء。

بالإضافةإلى مقاومتهاللتآكل،توفر شبكة شاشة PU أيضًا مقاومة ممتازةللتآكل。 شبكة الشاشة PU مقاومة للمواد الكيميائية، الأحماض، والقلويات، ممايجعلهامناسبة للتطبيقات التي تتم فيهامعالجةالمواد المسببةللتآكل。 تضمنمقاومةالتآكلهذه أن تحافظ شبكة شاشة PU على سلامتهاوأدائهاحتىفي ظروفالتشغيل القاسية。

ميزةأخرى لشبكة شاشة PU هي سهولة التركيبوالصيانة。 PU بسهولةعلىشاشاتنزح المياه، وتتطلبالحد الأدنىمنالصيانة لإبقائهافيحالة مثالية。 يمكنأنيساعدهذافي تقليلوقتالتوقفعن العملوتكاليف الصيانة، مما يجعل شبكة غربال PUخيارًافعالاًمن حيث التكلفة لتطبيقات نزحالمياه。

في الختام، توفر شبكة غربال PUالعديدمن المزايامقارنة بالأنواعالأخرىمن الألواحالشبكية لشاشات نزح المياه。 إنمقاومتهالعالية للتآكل، ومقاومته للتآكل، والمتانة تجعلهخيارًاموثوقًا وفعالًالمختلف تطبيقاتنزحالمياه。 فيحينأنالأنواع الأخرىمنالألواح الشبكيةقديكونلها مميزاتهاالخاصة،إلا أن شبكة الشاشة PU تتميز بأدائهاوطولعمرها وفعاليتهامنحيث التكلفة。 سواء كنت تعمل في مجال التعدينأوالمحاجرأو PU تعد خيارًا متعدد الاستخداماتوموثوقًا لاحتياجات نزح المياه الخاصةبك。

واحدة من المزايا الرئيسية لشبكة شاشة PU هي مقاومتها العالية للتآكل. يمكن لشبكة شاشة PU أن تتحمل التأثيرات الكاشطة للمواد التي تتم معالجتها، مثل الرمل، الحصى، أو الفحم. وهذا يجعل شبكة شاشة PU مثالية للتطبيقات التي تتطلب مقاومة عالية للتآكل، كما هو الحال في التعدين أو المحاجر أو البناء.

بالإضافة إلى مقاومتها للتآكل، توفر شبكة شاشة PU أيضًا مقاومة ممتازة للتآكل. شبكة الشاشة PU مقاومة للمواد الكيميائية، الأحماض، والقلويات، مما يجعلها مناسبة للتطبيقات التي تتم فيها معالجة المواد المسببة للتآكل. تضمن مقاومة التآكل هذه أن تحافظ شبكة شاشة PU على سلامتها وأدائها حتى في ظروف التشغيل القاسية.

ميزة أخرى لشبكة شاشة PU هي سهولة التركيب والصيانة. يمكن تركيب شبكة شاشة PU بسهولة على شاشات نزح المياه، وتتطلب الحد الأدنى من الصيانة لإبقائها في حالة مثالية. يمكن أن يساعد هذا في تقليل وقت التوقف عن العمل وتكاليف الصيانة، مما يجعل شبكة غربال PU خيارًا فعالاً من حيث التكلفة لتطبيقات نزح المياه.

في الختام، توفر شبكة غربال PU العديد من المزايا مقارنة بالأنواع الأخرى من الألواح الشبكية لشاشات نزح المياه. إن مقاومته العالية للتآكل، ومقاومته للتآكل، والمتانة تجعله خيارًا موثوقًا وفعالًا لمختلف تطبيقات نزح المياه. في حين أن الأنواع الأخرى من الألواح الشبكية قد يكون لها مميزاتها الخاصة، إلا أن شبكة الشاشة PU تتميز بأدائها وطول عمرها وفعاليتها من حيث التكلفة. سواء كنت تعمل في مجال التعدين أو المحاجر أو البناء، فإن شبكة غربال PU تعد خيارًا متعدد الاستخدامات وموثوقًا لاحتياجات نزح المياه الخاصة بك.