shaker Polyurethane flip flop plate Manufacture Ore

Benefits of Using Shaker polyurethane Flip Flop Plates in Industrial Applications

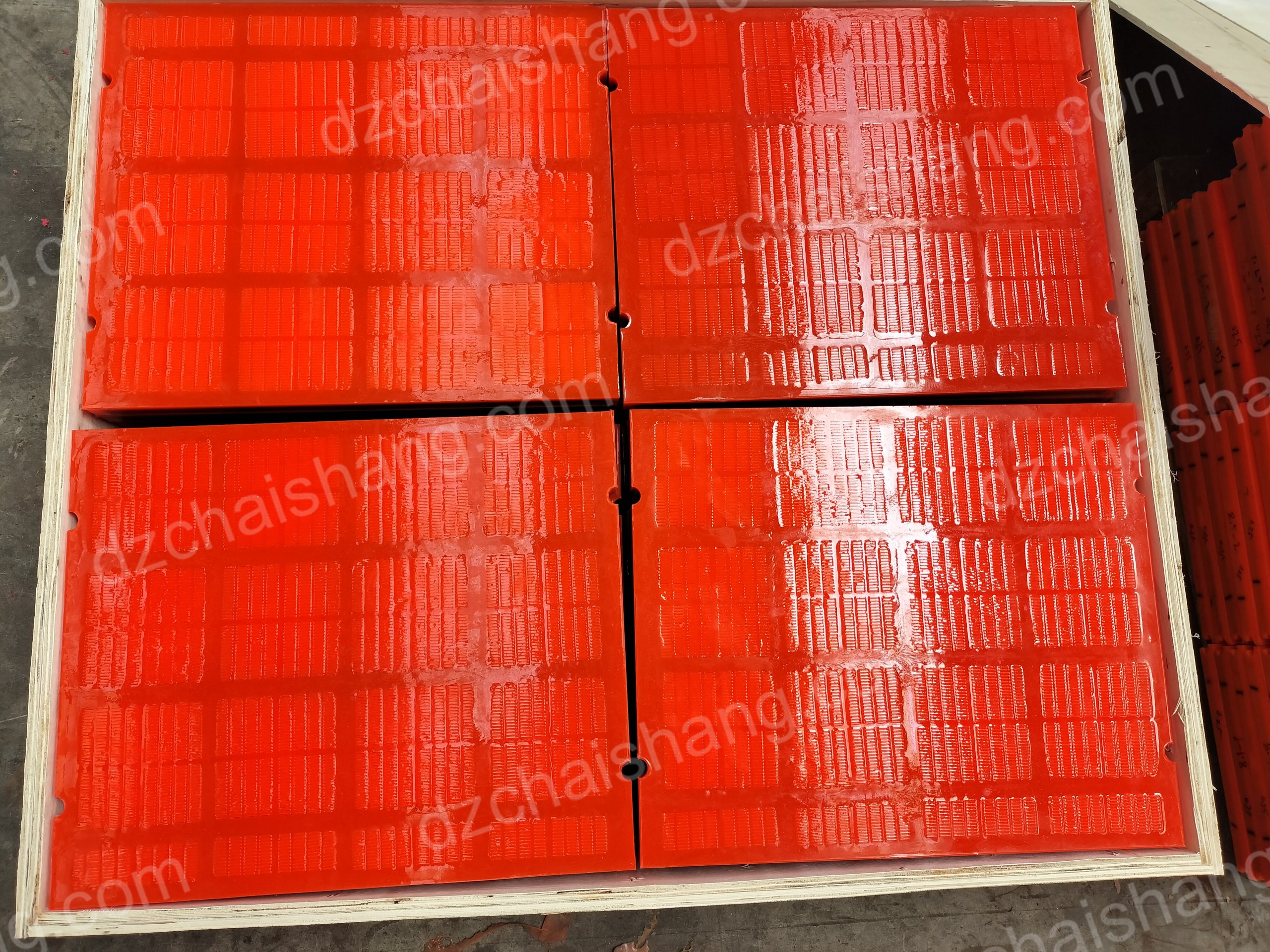

Polyurethane flip flop plates are a crucial component in many industrial applications, providing a durable and reliable solution for material handling and processing. One company that specializes in the manufacture of high-quality polyurethane flip flop plates is Shaker Polyurethane. With their expertise and commitment to excellence, Shaker Polyurethane has become a trusted name in the industry.

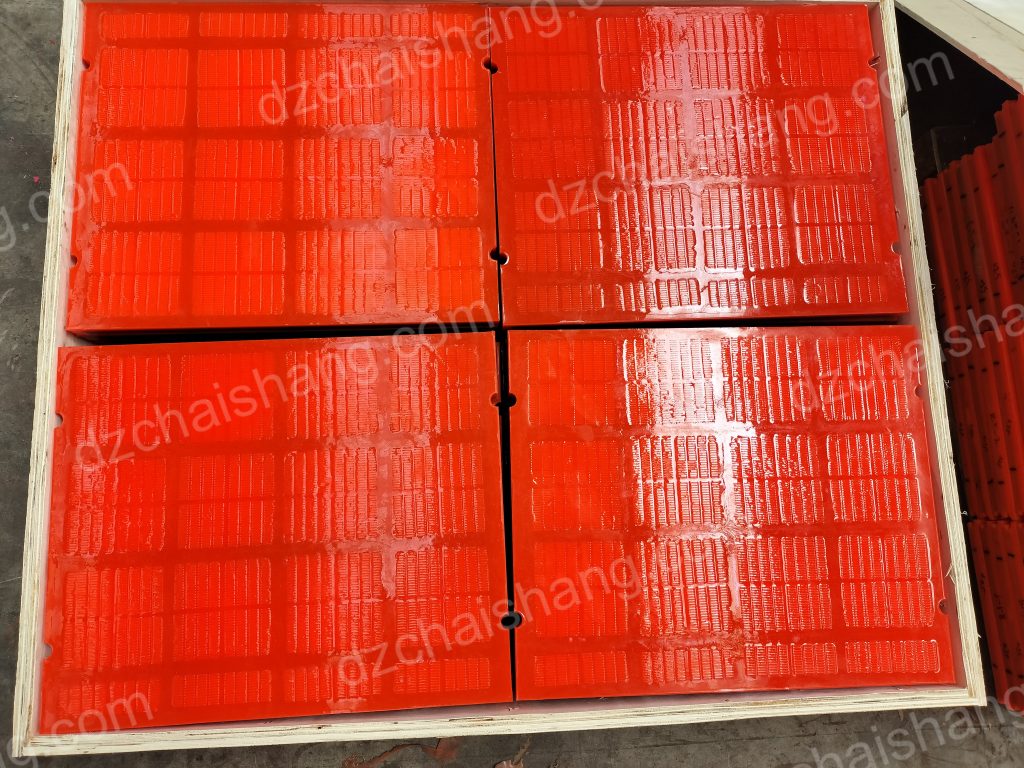

One of the key benefits of using Shaker Polyurethane flip flop plates is their exceptional durability. Made from high-quality polyurethane materials, these plates are designed to withstand the rigors of heavy-duty industrial use. Whether it’s handling abrasive materials or enduring high-impact loads, Shaker Polyurethane flip flop plates are built to last.

In addition to their durability, Shaker Polyurethane flip flop plates also offer superior performance. The unique design of these plates allows for efficient material flow, reducing downtime and increasing productivity. With their smooth surface and low coefficient of friction, Shaker Polyurethane flip flop plates help to minimize material buildup and prevent jams, ensuring a smooth and uninterrupted workflow.

Another advantage of using Shaker Polyurethane flip flop plates is their versatility. Available in a range of sizes and configurations, these plates can be customized to meet the specific needs of different industrial applications. Whether it’s sorting, screening, or conveying materials, Shaker Polyurethane flip flop plates can be tailored to fit the requirements of any project.

Furthermore, Shaker Polyurethane flip flop plates are easy to install and maintain, saving time and money for industrial operations. With their simple design and durable construction, these plates require minimal upkeep, allowing for hassle-free operation and long-term reliability. This makes them a cost-effective solution for businesses looking to improve efficiency and reduce maintenance costs.

In conclusion, Shaker Polyurethane flip flop plates offer a range of benefits for industrial applications. From their exceptional durability and performance to their versatility and ease of maintenance, these plates provide a reliable and efficient solution for material handling and processing. With Shaker Polyurethane’s commitment to quality and innovation, businesses can trust in the reliability and performance of their flip flop plates for years to come.

Step-by-Step Guide to Manufacturing Ore with Shaker Polyurethane Flip Flop Plates

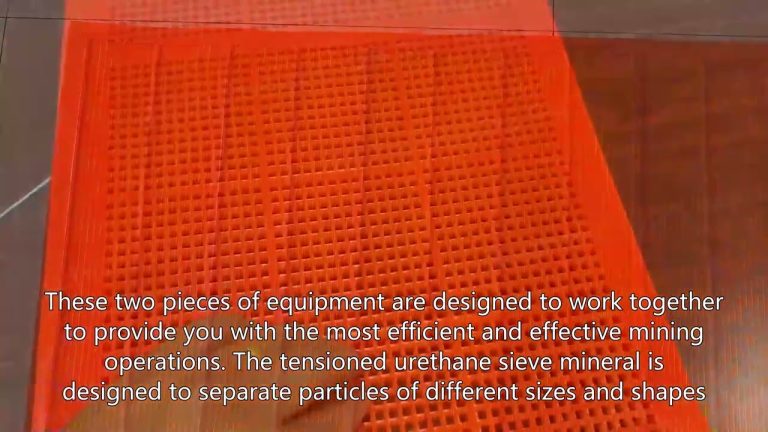

Polyurethane flip flop plates are a crucial component in the manufacturing process of ore. These plates are designed to efficiently separate materials based on size, ensuring that the final product meets the desired specifications. In this article, we will provide a step-by-step guide to manufacturing ore with shaker polyurethane flip flop plates.

The first step in the process is to gather all the necessary materials and equipment. This includes the shaker polyurethane flip flop plates, the ore to be processed, and any additional tools needed for the job. It is important to ensure that all equipment is in good working condition before beginning the manufacturing process.

Once all the materials are gathered, the next step is to prepare the ore for processing. This may involve crushing, grinding, or other methods of size reduction to ensure that the ore is in the proper form for separation. It is important to carefully follow all safety protocols during this step to prevent accidents or injuries.

After the ore is prepared, it is time to feed it onto the shaker polyurethane flip flop plates. These plates are designed to vibrate at a high frequency, causing the ore to separate based on size. The larger pieces of ore will move to the top of the plates, while the smaller pieces will fall through to the bottom.

As the ore moves through the plates, it is important to monitor the process closely. This may involve adjusting the vibration frequency or angle of the plates to ensure that the separation is occurring efficiently. It is also important to periodically clean the plates to prevent buildup and maintain optimal performance.

Once the ore has been separated into the desired sizes, it can be collected and further processed as needed. This may involve additional steps such as washing, drying, or further size reduction before the final product is ready for use. It is important to carefully follow all processing guidelines to ensure that the ore meets the required specifications.

In conclusion, manufacturing ore with shaker polyurethane flip flop plates is a complex process that requires careful attention to detail and adherence to safety protocols. By following the steps outlined in this guide, manufacturers can efficiently separate materials based on size and produce high-quality ore for a variety of applications. With proper equipment and monitoring, the manufacturing process can be completed successfully, resulting in a final product that meets the desired specifications.