丝网、丝网材质、丝网尺寸

استكشافالأنواع المختلفةلشبكات الشاشةالسلكية

فهمأهميةأحجامشبكات الشاشةفيالصناعات المختلفة

شبكةالشاشة،وهيمادة متعددةالاستخدامات تستخدمفيمختلف الصناعات، هي نسيج منسوج مصنوع من أسلاك معدنيةأوأليافصناعية。 لايمكنالمبالغةفي أهميةأحجامشبكات الشاشة، لأنهاتلعب دورا حاسما في تحديد فعاليةوكفاءةعملية الفحص。 يؤثر حجم الشبكة، الذي يشير إلى عدد الفتحات في كلبوصةخطية،بشكل مباشرعلىحجمالجزيئات التييمكنأنتمرعبرها。 لذلك، يعد فهم أهمية أحجامشبكاتالشاشة أمرًاضروريًالصناعات مثلالتعدينوالبناء والزراعة،منبين صناعات أخرى.

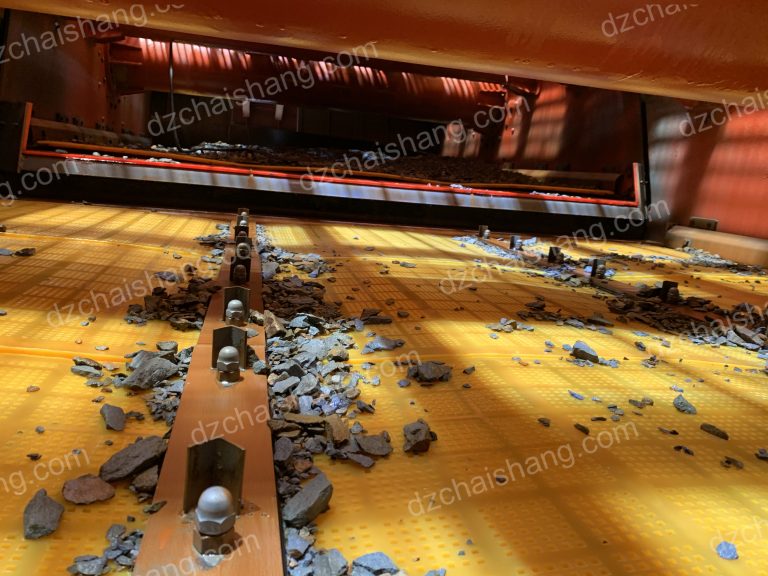

شبكات الشاشةالسلكية،أحد أكثرأنواعشبكات الشاشةشيوعًا،وعادةً ماتكونمصنوعةمن الفولاذ أو الفولاذ المقاومللصدأ。 إنمتانتهوقوتهتجعله خيارًامثاليًا للتطبيقات الثقيلةمثل التعدينواستغلال المحاجر。 تمتصميمشبكةالشاشة السلكيةلتحملقسوةهذه الصناعات، ممايوفر أداءً موثوقًا به حتى في أصعبالظروف。 يتم اختيار حجم فتحات الشبكةبعنايةبناءً علىحجمالجزيئاتالتي يجبفحصها。 على سبيل المثال، يمكن استخدامحجمشبكةأكبر لغربلةالصخورالأكبر حجمًا في المحجر، بينما يمكناستخدامحجمشبكة أصغرلفصلالجزيئات الدقيقة في المنجم.

تُعد مادةشبكةالغربلة عاملًاحاسمًاآخريؤثر علىأدائها 。 توفر المواد المختلفة مستويات مختلفةمن المتانةوالمرونة والمقاومةللعوامل البيئية。 علىسبيلالمثال،تتميز شبكةالشاشةالمصنوعة منالفولاذالمقاوم للصدأبمقاومةعالية للتآكلوبالتاليفهي مناسبةللاستخدامفي الصناعات التي قد تتعرض فيهاالشبكةللمواد المسببةللتآكل。 منناحيةأخرى،يمكن استخدامالمواد الاصطناعيةمثل البوليسترأوالنايلون فيالتطبيقاتالتي تتطلبدرجةأعلىمن المرونة。

يعداختيارحجم شبكةالشاشةوالمواد المناسبةعمليةمعقدة تتطلبفهمًاشاملاً للمتطلبات المحددةمن التطبيق。 عواملمثلحجمونوع الجسيمات التي سيتم فحصها، والظروف البيئية،والكفاءة المطلوبةلعمليةالفحص كلها تحتاج إلى أن تؤخذ فيالاعتبار。 على سبيل المثال، في صناعةالمواد الغذائية، قد تكون هناك حاجة إلى حجم شبكي دقيق لضمانعدموصولأي جزيئات غير مرغوبفيها إلىالمنتجالنهائي。 وبالمثل،فيصناعة المستحضرات الصيدلانية،يعدحجم الشبكةالدقيقأمرًا بالغ الأهميةلضمانفصل المكونات النشطةبشكل صحيح عن بقية المواد。

في الختام، لا يمكن المبالغةفيأهمية أحجامشبكاتالشاشةفي مختلفالصناعات。 يؤثرحجمالشبكةبشكل مباشرعلىكفاءة وفعاليةعملية الغربلة،ممايجعلها عاملاً حاسماً في صناعات مثل التعدين والبناءوالزراعة。 تلعبمادةشبكةالشاشة أيضًادورًامهمًا،حيث توفر المواد المختلفة مستويات مختلفةمن المتانةوالمرونة والمقاومةللعوامل البيئية。 لذلك، يعد الفهم الشامل للمتطلبات المحددة للتطبيقأمرًاضروريًا في اختيار حجم شبكة الشاشةوالمواد المناسبة。

دليلشامللاختيارمادة شبكةالشاشةالمناسبة

تلعبشبكةالشاشة،وهي مادةمتعددة الاستخداماتتستخدمفي مختلفالصناعات،دورًا حاسمًافيالعديدمن التطبيقات،بدءًامن شاشات النوافذ وحتى المرشحاتالصناعية。 تعتمدفعاليةشبكة الشاشة إلى حد كبير على مادتهاوحجمها،مما يجعل عملية الاختيار حاسمة。 توفرهذهالمقالة دليلاً شاملاً لاختيار مادةوحجمشبكةالشاشة المناسبة。

منالمهمأيضًاملاحظة أنقطرالسلكيؤثرعلى حجمالشبكة。 تؤدي الأسلاكالسميكة إلى فتحات أصغر، حتى لو كانعددالشبكات مرتفعًا。 لذلك، عند اختيار شبكة الشاشة، يجب مراعاةكل منعددالشبكةوقطر السلك.

في الختام، يعد اختيارمادةشبكة الشاشةالمناسبة وحجمهاقرارًاحاسمًا يمكن أن يؤثر بشكل كبير علىفعاليةالتطبيق。 يعتبرالفولاذالمقاوم للصدأوالألمنيوم والنحاسمنالمواد الشائعةالمستخدمةفي شبكات الغربلة السلكية،ولكلمنها خصائصهالفريدة。 يجبأنيسترشداختيار الموادبالتطبيق المقصودوالظروف البيئية。 وبالمثل، ينبغي اختيار حجم الشبكة، الذي يحدده عدد الشبكة وقطر السلك، علىأساسمستوىالترشيح أوالفصلالمطلوب。 منخلالالنظربعنايةفي هذهالعوامل،يمكن للمرءاختيارشبكة الشاشةالأكثرملاءمة لاحتياجاتهالخاصة。

不锈钢丝网以其强度和耐腐蚀性而闻名,使其成为恶劣环境的理想选择。它常用于采矿、石油和食品加工等行业。另一方面,铝丝网比不锈钢更轻、更柔韧。它具有防锈能力,常用于窗纱、通风板和防虫纱窗。铜丝网具有高导电性,通常用于电磁屏蔽应用。

丝网材料的选择应根据预期应用来指导。例如,如果网要在室外使用,则适合使用耐风化的材料,例如不锈钢或铝。对于需要导电性的应用,铜将是最佳选择。

筛网尺寸是另一个需要考虑的关键因素。筛网的目数是指每线性英寸的孔数,称为目数。较高的目数意味着较小的开口和较细的网目,而较低的目数表示较大的开口。筛孔尺寸的选择取决于所需的过滤或分离水平。例如,较高的目数适用于需要精细过滤的应用,例如制药行业。相反,较低的目数对于需要较大颗粒通过的应用(例如建筑行业)来说是理想的选择。

还需要注意的是,线径会影响网格尺寸。即使网目数很高,较粗的金属丝也会导致较小的开口。因此,在选择筛网时,应同时考虑筛网数量和丝径。

总而言之,选择正确的筛网材料和尺寸是一个关键的决定,可以显着影响应用的有效性。不锈钢、铝和铜是丝网常用的材料,每种材料都有其独特的性能。材料的选择应以预期应用和环境条件为指导。同样,由网目数和丝直径决定的网目尺寸应根据所需的过滤或分离水平来选择。通过仔细考虑这些因素,人们可以根据自己的具体需求选择最合适的筛网。