高品质聚氨酯矿用筛网、筛网面板

فوائد استخدام شاشات التعدينمنمادةالبولي يوريثينعاليةالجودة

تعد شاشات التعدين المصنوعةمنمادة البولي يوريثينعالية الجودةعنصرًاأساسيًا فيصناعةالتعدين。 توفر لوحات الشاشة الشبكيةهذهمجموعة واسعةمنالمزاياالتي تجعلهاخيارًاشائعًا لعمليات التعدينحول العالم。 في هذه المقالة، سوف نستكشفمزايااستخدام شاشات تعدين البولي يوريثينعاليةالجودة ولماذاتعدخيارًا متميزًامقارنة بالأنواعالأخرىمن الشاشات。

إحدىالفوائد الرئيسيةلاستخدام شاشات تعدين البولي يوريثينهيمتانتها。 مادةالبولييوريثين مادةقويةومرنةيمكنها تحملالظروفالقاسية لعملياتالتعدين。 علىعكسالشاشات الفولاذيةالتقليدية، فإنشاشاتالبولي يوريثينأقلعرضةللكسر أوالتآكل،ممايعني أنهاتتطلباستبدالًا أقلتكرارًا。 وهذالايوفرالوقت والمالفحسب،بليضمن أيضًاإمكانيةاستمرار عمليات التعديندون انقطاع。

بالإضافةإلى متانتها، تتميز شاشات التعدينالمصنوعةمن مادةالبولييوريثين أيضًابمقاومةعالية للتآكلوالتآكل。 وهذايجعلهامثالية للاستخدامفيالبيئات التي تتعرضفيها الشاشات للمواد الكاشطةأوالمواد المسببةللتآكل。 يمكنلشاشاتالبولي يوريثينأنتتحمل التآكلالناتجعن الاستخدامالمستمر، ممايضمنبقاءهافعالة لفترات أطولمن الوقت。

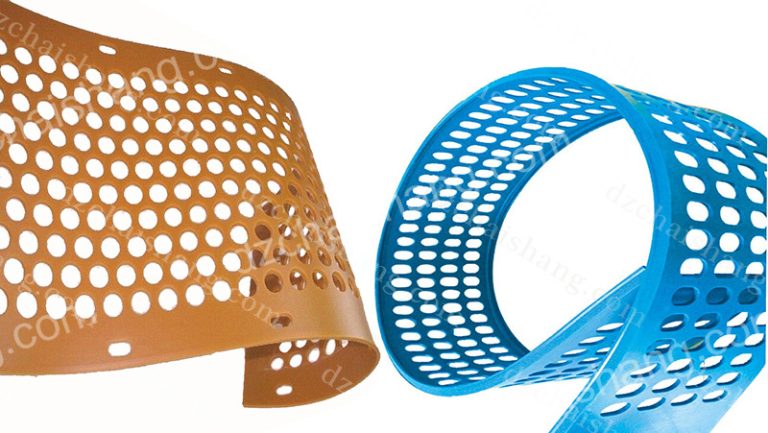

الميزةالأخرى لشاشات تعدينالبولي يوريثينهيمرونتها。 مادةالبولييوريثينهي مادةمتعددة الاستخداماتيمكن تشكيلهابأشكالوأحجام مختلفةلتلبية الاحتياجات المحددة لعمليات التعدين المختلفة。 تسمح هذهالمرونة بالتخصيص، بحيث يمكن تصميمالشاشاتلتناسب متطلبات كل منجم علىحدة.

توفر شاشات تعدين البولي يوريثينأيضًا كفاءةفحصفائقة。 يسمح تصميم هذه الشاشات بالفحصالأمثلللمواد، مما يؤدي إلى زيادة الإنتاجيةوتقليلوقت التوقفعنالعمل。 تسمح المنطقةالمفتوحة لشاشات البولي يوريثين بمرورالمزيدمن المواد، مما يزيد من الإنتاجيةويحسن الكفاءة الإجمالية。

علاوةعلى ذلك، تتميز شاشات تعدين البولي يوريثينبأنها خفيفةالوزنوسهلة التركيب。 وهذايجعلهاخيارًا عمليًالعمليات التعدينالتيتتطلب تغييرات أو صيانة متكررةللشاشة。 كماأنالطبيعةخفيفة الوزنلشاشاتالبولي يوريثينتقللالضغطعلى المعدات، مما يؤدي إلى تقليلالتآكلبمرور الوقت。

في الختام، توفر شاشات تعدينالبولييوريثين عاليةالجودةمجموعة واسعةمنالفوائدالتي تجعلهاخيارًامتميزًا لعملياتالتعدين。 إنمتانتهاومقاومتها للتآكلوالتآكل والمرونةوكفاءةالفحص وسهولةالتركيبكلها تساهم في فعاليتها في صناعةالتعدين。 منخلالاختيارشاشات البولي يوريثين، يمكن لعمليات التعدينتحسين الإنتاجية، وتقليلوقت التوقفعنالعمل، وزيادةالربحيةفي نهايةالمطاف.

كيفتعمل لوحات الشاشةالشبكية علىتحسينالكفاءةفي عمليات التعدين

تلعبشاشاتالتعدين المصنوعةمنمادة البولي يوريثينعالية الجودة، والمعروفة أيضًابألواحالشاشة الشبكية،دورًاحاسمًا فيتحسينالكفاءةفي عملياتالتعدين。 تمتصميمهذهالشاشات لتحملالظروفالقاسية لصناعةالتعدينوتوفر عددًامنالفوائدالتي تساعد على تبسيط عملية التعدين。

إحدىالمزايا الرئيسيةلاستخدام شاشات التعدين من مادة البولي يوريثينهي متانتها。 هذهالشاشاتمصنوعةمن مواد عالية الجودة مقاومةللتآكل،مما يجعلهامثالية للاستخدامفيبيئة المنجمالصعبة。 تضمنهذهالمتانةقدرة الشاشات على مقاومة المواد الكاشطةالتي غالبًاماتتممواجهتها أثناءعمليةالتعدين، ممايقللالحاجةإلى الاستبدالوالصيانة المتكررة。

بالإضافةإلى متانتها، تتميز شاشات التعدينالمصنوعةمن مادةالبولييوريثين أيضًابكفاءةعالية。 يسمح التصميمالشبكي لهذهالشاشاتبالفصل الفعالللمواد،مما يسهلعمليةاستخلاص المعادنالقيمةمن الخام。 يمكنأنتساعدهذه الكفاءةالمتزايدةفي تقليلأوقاتالمعالجة وتحسينالإنتاجية الإجماليةفيعمليات التعدين。

منالمزايا الأخرىلاستخدامشاشات تعدينالبولييوريثين هيتعدداستخداماتها。 يمكنتخصيصهذهالشاشات لتلبيةالاحتياجات المحددةلعملية التعدين،معتوفر خيارات لأحجام وتكوينات الشبكات المختلفة。 تسمح هذه المرونة بتحكم أكبرفيعمليةالغربلة، ممايضمنأنالشاشات قادرةعلىفصلالمواد ذات الأحجام المختلفة بشكلفعال。

تُعرفشاشات تعدينالبولييوريثين أيضًابمتطلبات الصيانةالمنخفضة。 علىعكسالشاشات المعدنيةالتقليدية، التي يمكنأنتصدأ وتتآكلبمرورالوقت، فإنشاشاتالبولي يوريثينمقاومةلهذه المشكلات。 وهذايعنيأنهيلزم إنفاق وقت وموارد أقل في صيانةالشاشات واستبدالها،ممايسمح بكفاءةأكبرفيعمليات التعدين。

علاوةعلىذلك، تتميزشاشاتالتعدين المصنوعةمنمادة البولي يوريثينبخفة الوزنوسهلةالتركيب。 وهذايجعلهاخيارًا فعالاً من حيث التكلفة لشركات التعدينالتي تتطلعإلىتحسين عملياتهادونكسرالبنك。 وتعني سهولة التثبيت أيضًاتقليلوقتالتوقف عنالعمل،ممايسمح بالتشغيلالمستمر وزيادةالإنتاجية.

نصائح الصيانة لإطالة عمر شاشات تعدين البولي يوريثين

تعد شاشات التعدين المصنوعةمنمادة البولي يوريثينمكونات أساسيةفيصناعة التعدين، لأنهاتلعب دورًاحاسمًافيفصل المعادنالثمينةعن النفايات。 وتتميزهذهالشاشات بمتانتهاومرونتها وكفاءةالفحصالعالية。 ومع ذلك، مثل أي معدات أخرى،تتطلبشاشات تعدينالبولييوريثين صيانةمناسبةلضمانطول عمرهاوالأداء الأمثل。

إحدىنصائح الصيانةالرئيسية لإطالة عمر شاشات تعدين البولي يوريثينهي التنظيفالمنتظم。 معمرورالوقت،يمكنأن تتراكمالأوساخ والحطاموالجزيئات المعدنيةعلىسطح الشاشة، ممايقللمن كفاءةالفحص。 ولمنعهذاالتراكم،من المهمتنظيفالشاشات بانتظامباستخدام الماءومنظفمعتدل。 تجنباستخدامالمواد الكيميائيةالقاسيةأو المواد الكاشطة، لأنها يمكنأنتلحقالضرر بمادةالبولي يوريثين。

بالإضافةإلى التنظيفالمنتظم،من المهمأيضًافحص الشاشات بحثًاعنأي علامات تآكلأوتلف。 تم تصميم شاشات التعدين المصنوعةمنمادة البولي يوريثينلتحمل الظروفالقاسيةلبيئة التعدين،ولكنهالا تزالعرضةللتآكلبمرور الوقت。 افحصالشاشاتبحثًاعن أي تمزقات أو ثقوب أو حواف مفكوكة، حيث يمكن أنيؤثرذلكعلىكفاءة الفحصويؤديإلىفشل مبكر.

إذاتمالعثورعلى أي ضرر أثناء الفحص، فمن المهممعالجتهعلى الفور。 يمكن إصلاح التمزقات أو الثقوبالصغيرة باستخدامموادالترقيع المصنوعةمنمادة البولي يوريثين، والتي تم تصميمها خصيصًا لهذا الغرض。 منخلالمعالجةالأضرار الطفيفة في وقت مبكر، يمكنكمنعهامنالتفاقم وإطالةعمر الشاشات。

نصيحةصيانة مهمةأخرىلشاشاتتعدين البولي يوريثينهي التخزينالمناسبعند عدمالاستخدام。 عندمالاتكونالشاشات قيدالتشغيل،قم بتخزينهافيمنطقة نظيفةوجافةوجيدة التهويةلمنعتراكم الرطوبةونموالعفن。 تجنبتكديسالشاشاتفوق بعضهاالبعض،لأنذلكقد يتسببفيتشوهوتلف لوحات الشاشة.

علاوةعلى ذلك، من المهم التعامل معالشاشاتبعناية أثناءالتثبيت والإزالة。 تجنباستخدامالقوة المفرطةأوالأشياء الحادةالتييمكنأن تسببضررًاللشاشات。 استخدممعداتوتقنيات الرفعالمناسبةلمنع ثني أو التواء ألواح الشاشة。 منخلالالتعاملمع الشاشات بعناية، يمكنك منع حدوث أضرار غير ضروريةوإطالةعمرها الافتراضي.

أخيرًا،من المهماتباعإرشادات الشركةالمصنعةلصيانة ورعايةشاشاتتعدين البولييوريثين。 قد يكون لدى كل مصنع توصيات محددةللتنظيف والتخزينوالتعاملمع الشاشات، لذا تأكد من استشارةدليلالمنتجأو اتصلبالشركةالمصنعة للحصولعلىإرشادات。

فيالختام،تعدالصيانة المناسبةضرورية لإطالة عمر شاشات تعدين البولييوريثين。 باتباعنصائحالصيانة هذه، يمكنك التأكد من بقاءشاشاتكفيحالة مثاليةوالاستمرارفي تقديم أداء فحص فعال في صناعةالتعدين。 يعدالتنظيفالمنتظم والفحصوالإصلاحات السريعةوالتخزين المناسبوالتعامل الدقيقوالالتزام بإرشاداتالشركة المصنعةمنالعوامل الرئيسيةفيالحفاظعلى طولعمرشاشاتتعدين البولييوريثين。 منخلالاستثمارالوقت والجهد في الصيانة، يمكنكزيادةالعمر الافتراضي لشاشاتك وتوفيرتكاليف الاستبدالفيالنهاية.

聚氨酯采矿筛网是采矿业的重要组成部分,因为它们在从废料中分离有价值的矿物方面发挥着至关重要的作用。这些筛子以其耐用性、灵活性和高筛分效率而闻名。然而,与任何其他设备一样,聚氨酯采矿筛网需要适当的维护,以确保其使用寿命和最佳性能。

延长聚氨酯采矿筛网使用寿命的关键维护技巧之一是定期清洁。随着时间的推移,污垢、碎片和矿物颗粒会积聚在筛子表面,降低筛分效率。为了防止这种情况的发生,定期用水和温和的清洁剂清洁屏幕非常重要。避免使用刺激性化学品或研磨材料,因为它们会损坏聚氨酯材料。

除了定期清洁之外,检查屏幕是否有任何磨损或损坏的迹象也很重要。聚氨酯采矿筛网旨在承受采矿环境的恶劣条件,但随着时间的推移,它们仍然容易磨损。检查筛网是否有任何撕裂、孔洞或松动的边缘,因为这些会影响筛分效率并导致过早失效。

如果在检查过程中发现任何损坏,请务必立即解决。小撕裂或孔洞可以使用专门为此目的设计的聚氨酯修补材料进行修复。通过尽早解决轻微损坏,您可以防止其恶化并延长筛网的使用寿命。

聚氨酯矿用筛网的另一个重要维护技巧是在不使用时正确存放。当筛网不运行时,请将其存放在清洁、干燥且通风良好的区域,以防止水分积聚和霉菌生长。避免将筛网堆叠在一起,因为这可能会导致筛板变形和损坏。

此外,在安装和拆卸过程中小心处理筛网也很重要。避免使用过度用力或尖锐物体,以免损坏屏幕。使用适当的起重设备和技术来防止筛板弯曲或扭曲。通过小心处理筛网,您可以防止不必要的损坏并延长其使用寿命。

最后,遵循制造商的聚氨酯矿用筛网维护和保养指南非常重要。每个制造商可能对筛网的清洁、储存和处理有具体的建议,因此请务必查阅产品手册或联系制造商以获得指导。

总而言之,适当的维护对于延长聚氨酯矿用筛网的使用寿命至关重要。通过遵循这些维护提示,您可以确保您的筛网保持最佳状态,并继续在采矿业提供高效的筛分性能。定期清洁、检查、及时维修、正确存放、小心搬运以及遵守制造商指南是保持聚氨酯采矿筛网使用寿命的关键因素。通过投入时间和精力进行维护,您可以最大限度地延长屏幕的使用寿命,并最终节省更换成本。