Màn hình polyurethane tần số cao, lưới màn hình PU

فوائد استخدام شاشة البولي يوريثان عالية التردد في عمليات الفحص

ملالم pu °.

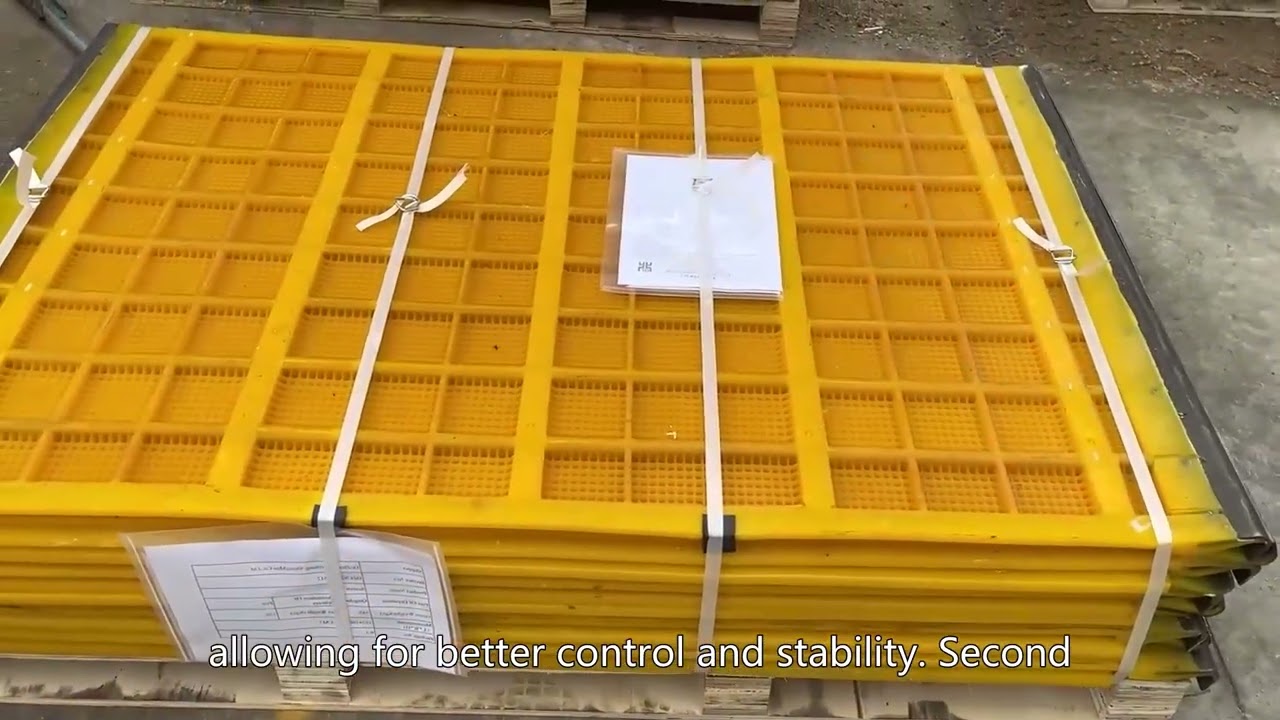

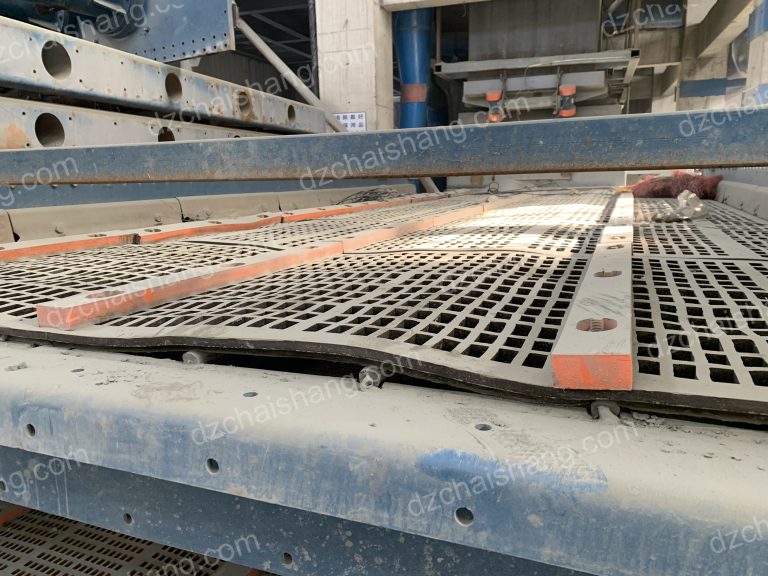

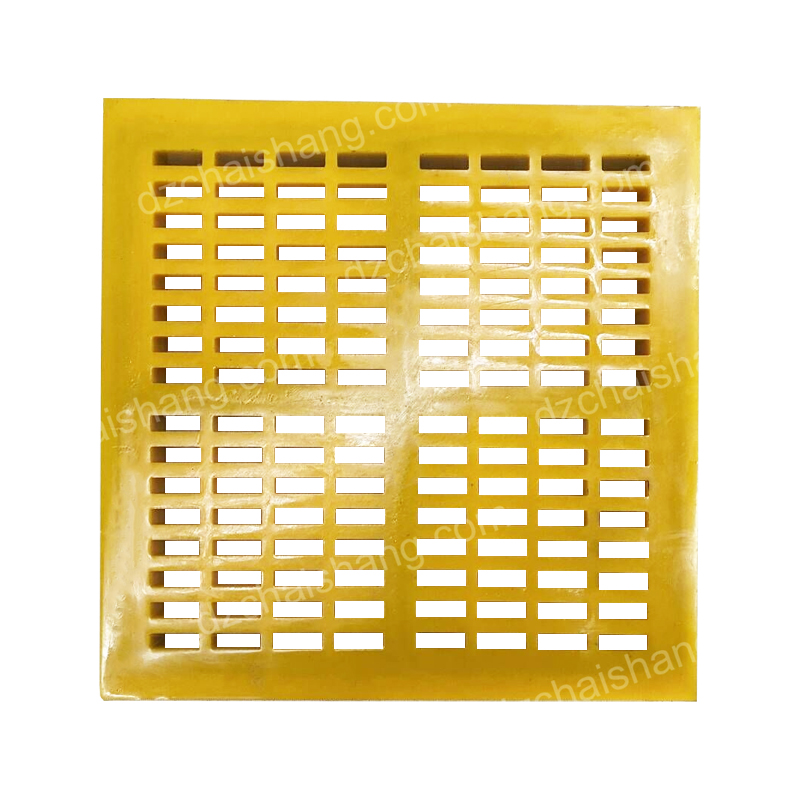

واحدة من المزايا الرئيسية لشاشات البولي يوريثان عالية التردد هي متانةها. البولي يوريثان هو مادة مرنة للغاية يمكنها تحمل ظروف التشغيل القاسية ، بما في ذلك المواد الكاشطة والأحمال ذات التأثير العالي. تترجم هذه المتانة إلى عمر الشاشة الأطول وتقليل تكاليف الصيانة لعمليات الفحص. بالإضافة إلى ذلك ، فإن شاشات البولي يوريثان مقاومة للتآكل والأضرار الكيميائية ، مما يجعلها مثالية للاستخدام في الصناعات التي يكون فيها التعرض للمواد التآكل أمرًا شائعًا. يمكن تشكيل مادة البولي يوريثان في أشكال وأحجام مختلفة ، مما يسمح بالتخصيص لتلبية متطلبات الفحص المحددة. تمتد هذه المرونة أيضًا إلى فتحات الشاشة ، والتي يمكن تصميمها لتحقيق فصل حجم الجسيمات المطلوب. يضمن هذا المستوى من التخصيص أن عمليات الفحص يمكن أن تحقق الكفاءة والدقة المثلى في فصل الجسيمات. تساعد الاهتزازات عالية التردد الناتجة عن هذه الشاشات على زيادة كفاءة فصل الجسيمات ، مما يؤدي إلى ارتفاع إنتاجية وتحسين جودة المنتج. إن فتحات الشبكة الدقيقة لشاشات البولي يوريثان تمنع أيضًا التعمية والمربعة ، مما يضمن أداء الفحص المتسق بمرور الوقت. يؤدي انخفاض وزن شاشات البولي يوريثان مقارنة بشاشات الصلب أيضًا إلى انخفاض استهلاك الطاقة أثناء التشغيل. هذه كفاءة الطاقة ، إلى جانب العمر الطويل لشاشات البولي يوريثان ، تساهم في توفير التكاليف الإجمالية لعمليات الفحص. هذه الشاشات مثالية للصناعات التي تتطلب فصلًا فعالًا ودقيقًا للجسيمات ، مثل التعدين ، والمعالجة الإجمالية ، وإعادة التدوير. من خلال الاستثمار في شاشات البولي يوريثان عالية التردد ، يمكن أن تحسن عمليات الفحص الإنتاجية ، وتقليل تكاليف الصيانة ، وتحقيق نتائج فحص عالية الجودة.

i وم 20 é أ الم أ ا Seln المل ة ع إط ق ق ق ق ق ق ق ق ق ا ا ا ة.

i وم 20 é أل الم 라이 أو اليد 변재 médi أل الم 라이 â ö جان üve sie الرين المنا e 테. Seln الملرطة “Uuvre أ ال 없음 الم رطة – â 인 인 الضغط ع â ا ش 탈바닥 أ أ أ أ أ ³ ³ ³ ³ ³ أ 탈바닥 أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ أ â â â â Â ³ ³ ³ funys ة ع ع إط ق ق ق ق ق ق ق ق ق ق ق ق ق ا ا ا ا ا ا ا ا ة.

i وم 20 é أل الم 라이 أو اليد 변재 Médi أل الم 라이 â Örpper جانن üten sie الرين المنا e 테. Seln الملرطة “uuvre أو ال 없음 الم رطة – Uvuvre 인 인 인 الضغط عند 우리는 fra ال اش 탈바닥 أ أ â ³ ³ ³ ³ ³ ³ ا ا ا ا ا ا ا ا ا ا ا الصيانة المنا Ros Ros Fung ة ع ع إط ق ق ق ق ق ق ق ق ق ق ق ق ق ق ق ادم ة.