Trong khai thác lưới màn hình polyurethane mô -đun

فوائد استخدام شبكة شاشة البولي يوريثان المعيارية في عمليات التعدين

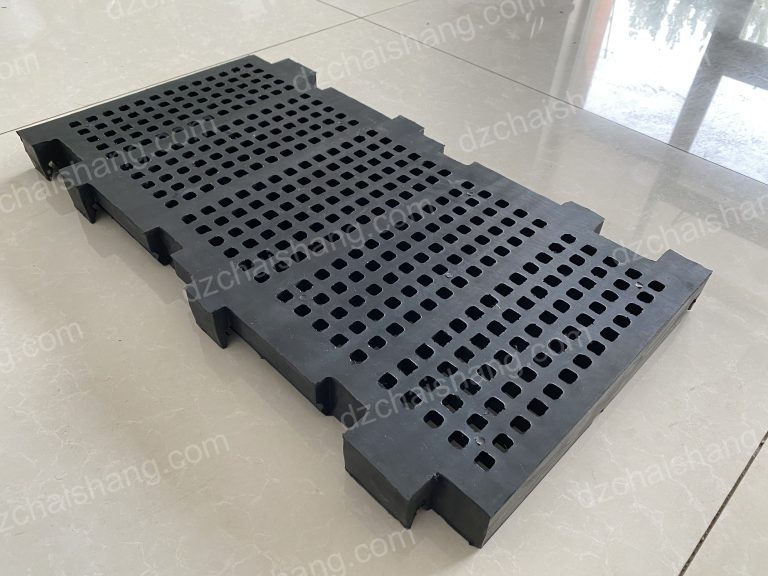

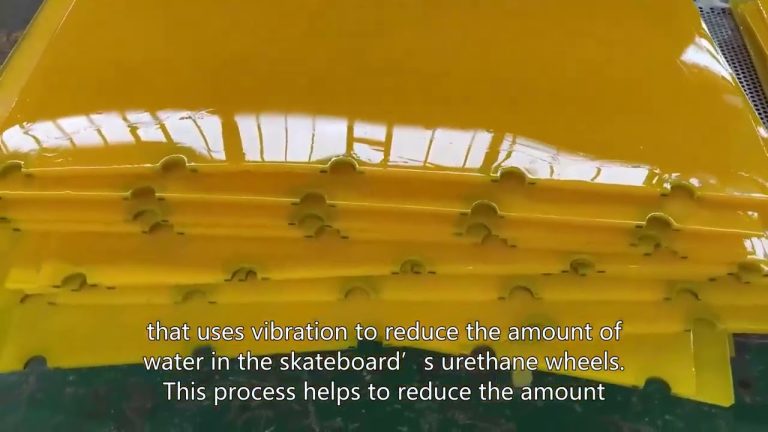

ومع ذلك ، ظهرت شبكة شاشة البولي يوريثان المعيارية كبديل شائع في عمليات التعدين بسبب فوائدها العديدة. يتكون هذا النوع من شبكة الشاشة من البولي يوريثان ، وهي مادة متينة ومرنة توفر العديد من المزايا على مواد الفحص التقليدية. البولي يوريثان هو مادة مرنة للغاية يمكنها تحمل الظروف القاسية لعمليات التعدين ، بما في ذلك المواد الكاشطة وقوى التأثير العالي. هذا يعني أن شبكة شاشة البولي يوريثان أقل عرضة للارتداء أو الانهيار ، مما يؤدي إلى انخفاض تكاليف الصيانة ووقت التوقف لعمليات التعدين. على عكس لوحات الشاشة المعدنية أو المطاطية ، فإن شبكة شاشة البولي يوريثان خفيفة الوزن وسهلة التعامل معها ، مما يجعل التثبيت والاستبدال سريعًا وفعالًا. تتيح هذه المرونة أيضًا تخصيصًا سهلاً لألواح الشاشة لتناسب متطلبات الفحص المحددة ، مما يؤدي إلى تحسين كفاءة الفحص والدقة. يتيح تصميم المنطقة المفتوحة لشاشة شاشة البولي يوريثان زيادة كفاءة الإنتاجية وفحص ، مما يؤدي إلى ارتفاع معدلات الإنتاج وتقليل استهلاك الطاقة. كما أن خصائص التنظيف الذاتي للبولي يوريثان تمنع التعمية والربط ، مما يضمن نتائج فحص متسقة وموثوقة.

علاوة على ذلك ، فإن شبكة شاشة البولي يوريثان المعيارية صديقة للبيئة. البولي يوريثان هو مادة قابلة لإعادة التدوير يمكن إعادة استخدامها وإعادة استخدامها ، مما يقلل من النفايات وتقليل التأثير البيئي لعمليات التعدين. يزداد أهمية جانب الاستدامة في صناعة التعدين اليوم ، حيث تتعرض الشركات لضغوط لتقليل بصمة الكربون والتشغيل بطريقة أكثر مسؤولية بيئيًا. من قابليتها ومرونتها إلى أداء الفحص المتفوق والاستدامة البيئية ، توفر شبكة شاشة البولي يوريثان حلاً فعالًا وفعالًا من حيث التكلفة لفحص التطبيقات في صناعة التعدين. من خلال اختيار شبكة شاشة البولي يوريثان المعيارية ، يمكن لشركات التعدين تحسين عمليات الفحص الخاصة بها ، وزيادة الإنتاجية ، وتقليل تكاليف الصيانة ، مما يؤدي في النهاية إلى عملية أكثر نجاحًا واستدامة.

كيفية تثبيت وصيانة شبكة شاشة البولي يوريثان بشكل صحيح في معدات التعدين

في صناعة التعدين ، فإن الكفاءة والإنتاجية هي العوامل الرئيسية في ضمان نجاح العمليات. أحد المكونات الحاسمة في معدات التعدين التي تلعب دورًا مهمًا في تحقيق هذه الأهداف هو شبكة الشاشة. أصبحت شبكة شاشة البولي يوريثان المعيارية خيارًا شائعًا للعديد من عمليات التعدين بسبب متانتها ومرونتها وفعالية التكلفة. ومع ذلك ، يعد التثبيت والصيانة المناسبين لهذا النوع من شبكة الشاشة ضرورية لضمان الأداء الأمثل وطول العمر. أولاً وقبل كل شيء ، من الأهمية بمكان فحص شبكة الشاشة بعناية لأي عيوب أو تلف قبل التثبيت. أي عيوب في الشبكة يمكن أن تساثر فعاليتها وتؤدي إلى التآكل المبكرة. بمجرد فحص شبكة الشاشة واعتبرها في حالة جيدة ، من المهم التأكد من حجمها بشكل صحيح لتناسب المعدات التي سيتم تثبيتها عليها. بمجرد أن تنظف الجهاز ، يمكن وضع شبكة الشاشة بعناية وتأمينها في المنطقة المحددة. من المهم التأكد من توتر الشبكة بشكل صحيح لمنع التراجع أو التحول أثناء العملية. بالإضافة إلى ذلك ، يجب تشديد جميع السحابات بشكل آمن لمنع الشبكة من القدوم. واحدة من أهم مهام الصيانة هي التنظيف المنتظم لشبكة الشاشة لإزالة أي تراكم من المواد أو الحطام التي يمكن أن تسد الشبكة وتقليل فعاليتها. يمكن القيام بذلك باستخدام فرشاة أو الهواء المضغوط لإزالة أي جزيئات قد تكون عالقة في الشبكة. إذا تم العثور على أي دموع أو ثقوب أو عيوب أخرى ، فيجب إصلاحها أو استبدالها على الفور لمنع المزيد من الأضرار التي لحقت بالشبكة. من المهم أيضًا التحقق من توتر الشبكة بانتظام لضمان توتر وآمن بشكل صحيح.

الصيانة السليمة لشبكة شاشة البولي يوريثان المعيارية في معدات التعدين ضرورية لضمان الأداء الأمثل وطول العمر. باتباع الخطوات الموضحة أعلاه ، يمكن لمشغلي التعدين زيادة كفاءة عملياتهم وإنتاجيتها إلى الحد الأقصى مع تقليل وقت التوقف والإصلاحات المكلفة. مع التثبيت والصيانة المناسبين ، يمكن أن تكون شبكة شاشة البولي يوريثان المعيارية أحد الأصول القيمة في صناعة التعدين ، مما يوفر حلول فحص موثوقة ودائمة لمجموعة واسعة من التطبيقات.

খনির সরঞ্জামগুলিতে মডুলার পলিউরেথেন স্ক্রিন জালটির যথাযথ রক্ষণাবেক্ষণ সর্বোত্তম কর্মক্ষমতা এবং দীর্ঘায়ু নিশ্চিত করার জন্য প্রয়োজনীয়। উপরে বর্ণিত পদক্ষেপগুলি অনুসরণ করে, খনির অপারেটররা ডাউনটাইম এবং ব্যয়বহুল মেরামত হ্রাস করার সময় তাদের ক্রিয়াকলাপগুলির দক্ষতা এবং উত্পাদনশীলতা সর্বাধিক করতে পারে। যথাযথ ইনস্টলেশন এবং রক্ষণাবেক্ষণের সাথে, মডুলার পলিউরেথেন স্ক্রিন জাল খনির শিল্পে একটি মূল্যবান সম্পদ হতে পারে, বিভিন্ন অ্যাপ্লিকেশনগুলির জন্য নির্ভরযোগ্য এবং টেকসই স্ক্রিনিং সমাধান সরবরাহ করে