橡胶筛网,橡胶筛网,橡胶筛网

استكشافتعدد استخدامات الشاشات المطاطية واستخداماتها

لقد ظهرت الشاشات المطاطية، المعروفة أيضًاباسمالغربلة المطاطية، كحل متعدد الاستخداماتوفعال للغايةفيمختلف الصناعات。 تمتصميمهذهالشاشات لتوفيرأداءفائق ومتانة ومرونة، مما يجعلهاخيارًامثاليًا للعديدمنالتطبيقات。 تهدفهذهالمقالةإلى استكشافتعدد استخدامات الحواجز المطاطية واستخداماتها،وتسليط الضوءعلىخصائصها وفوائدها الفريدة。

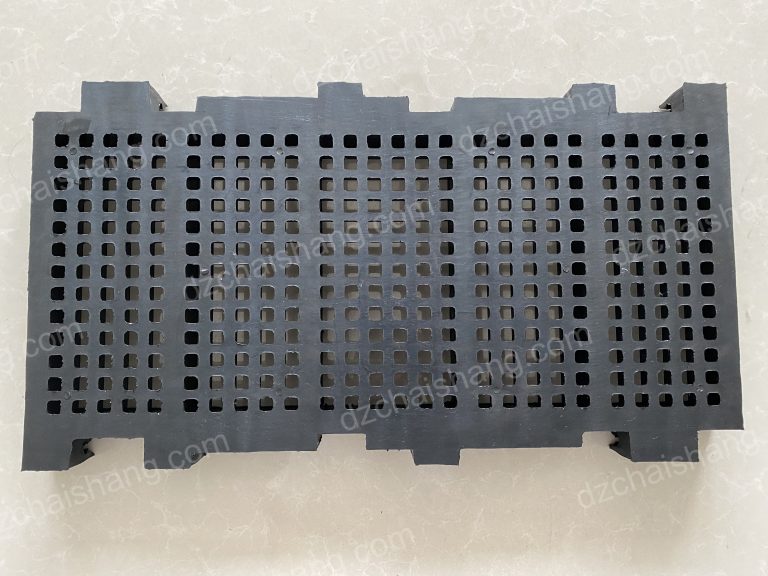

تُستخدم الحواجزالمطاطيةبشكل أساسي في صناعات التعدينوالتجميع،حيث تلعبدورًاحاسمًافي فصلالموادوتحجيمها。 وهي مصممة للتعامل مع التطبيقات الثقيلة، وتحملمستوياتعاليةمن الضغطالميكانيكي والتآكل。 تسمح المرونةالمتأصلة للمطاطلهذهالشاشات بامتصاصالصدمات ومقاومةالتلف، وبالتالي تعزيزعمرها الافتراضيوتقليل متطلبات الصيانة.

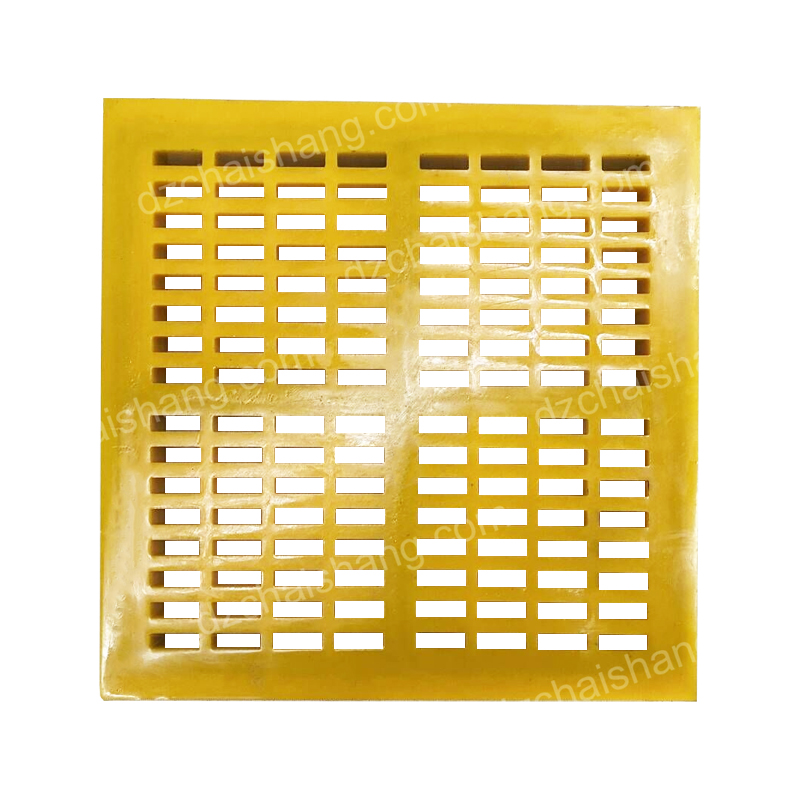

يمتد تعدد استخدامات الشاشات المطاطيةإلى ماهوأبعدمنمتانتها。 وهي متوفرة في مجموعة واسعةمنالأحجام والأشكالوالتكوينات، ممايسمحبالتخصيص لتلبيةالاحتياجات التشغيليةالمحددة。 سواء كانت لوحة مسطحة لمهامالفحصالبسيطةأو شاشةمشدودةلعمليات فصلأكثرتعقيدًا،يمكن تصميمالحواجز المطاطيةلتناسبأي متطلبات。

إحدىالمزايا الرئيسيةللشاشات المطاطيةهيقدرتهاعلى تقليلالضوضاء。 علىعكسالشاشات المعدنية، التي يمكن أن تولد ضوضاء كبيرة أثناء التشغيل، تعمل الشاشات المطاطيةبهدوء。 ولايساهمهذافيتوفير بيئةعملأكثرأمانًا وراحة فحسب، بل يساعد الشركات أيضًاعلى الالتزامبلوائح الضوضاء。

علىالرغممنمزاياها العديدة،فمنالمهم ملاحظةأنالشاشات المطاطيةليستمناسبة لجميعالتطبيقات。 قد لا تعمل بشكل جيد في درجات الحرارةالقصوى أوفيوجودمواد كيميائيةمعينة。 لذلك، من الضروري مراعاةالشروط والمتطلبات المحددة لكلتطبيقعنداختيارحل الفحص。

في الختام، توفر الشاشات المطاطيةحلاً متعدد الاستخدامات وفعالًالمجموعةواسعة منالتطبيقات。 إنمتانتهاومرونتها وكفاءتهاتجعلها خيارًامثاليًا لصناعات مثل التعدين والركام، في حين تزيد قدرتهاعلىتقليل الضوضاءوخصائصتوفير الطاقةمنجاذبيتها。 علاوةعلىذلك،فإن استخدامهافيالأجهزة الإلكترونية الاستهلاكيةيسلط الضوءعلىقدرتهاعلى التكيفوإمكاناتها الواسعةالنطاق。 ومع ذلك، مثل أي مادة، فإن لها حدودها وقد لا تكونمناسبةلجميع التطبيقات。 لذلك، يعد النظر بعناية في المتطلبات والشروط المحددةأمرًاضروريًا عند اختيار الشاشة المطاطية。

لقداكتسبفحصالمطاط، وهوعنصرحاسمفيمختلف التطبيقات الصناعية، قوةجذبكبيرةفي السنواتالأخيرة。 ويرجعذلكفيالمقام الأولإلىخصائصه الفريدةوالمزايا العديدةالتييقدمها مقارنةبموادالفحص التقليدية。 لقد أحدث استخدام الشاشات المطاطيةفي صناعات مثل التعدين والبناءوإعادة التدويرثورةفيطريقة عملهذهالقطاعات،مما أدىإلىتعزيزالكفاءة والإنتاجية。

منأبرز مزاياغربلةالمطاطهي متانتها。 تشتهرالشاشات المطاطيةبمرونتها وقدرتهاعلىتحمل الظروفالقاسية。 إنهامقاومةللتآكل والجروح والتمزق، مما يجعلهامثالية للاستخداماتالشاقة。 تُترجمهذهالمتانةإلى عمر خدمة أطول، مما يقلل منتكراراستبدال الشاشةوبالتاليخفض تكاليف التشغيل。

بالإضافةإلى متانتها، توفر الشاشات المطاطيةأيضًاأداءً فائقًا。 وهي مصممة لتوفير كفاءة فحصعالية،ممايضمنفصل الموادبشكلمناسب。 وهذامهمبشكلخاصفي صناعات مثل التعدين والبناء، حيث يمكن لجودةعمليةالفصلأن تؤثربشكلكبيرعلى الإنتاجيةالإجمالية。 تتمتعالحواجز المطاطيةأيضًابقدرة تحملعالية،ممايسمح لهابالتعاملمعكميات كبيرةمنالمواددون المساسبأدائها。

ميزة أخرىمهمةلغربلة المطاطهيقدرتهاعلى تقليلالضوضاء。 في البيئات الصناعية، يمكنأنيشكلالتلوث الضوضائيمصدرقلق كبير، حيث لا يؤثر على بيئةالعملفحسب،بل أيضًاعلىالمجتمعات المحيطة。 يمكنللشاشات المطاطية،نظرًا لخصائصهاالكامنةفي امتصاصالصوت،أنتقلل بشكلكبيرمنالضوضاء الناتجةأثناءعملية الغربلة。 لايؤديهذاإلىتحسين ظروف العمل فحسب، بل يساعد الصناعات أيضًا علىالامتثالللوائح الضوضاء。

توفرالحواجز المطاطيةأيضًا المرونةمنحيثالتصميم والتخصيص。 يمكنتصنيعهابأشكال وأحجاموتكوينات مختلفة لتلبية متطلبات التطبيقالمحددة。 تسمح هذهالمرونة للصناعاتبتحسين عمليات الفحصالخاصة بها، مما يعزز الكفاءة والإنتاجية。 علاوةعلىذلك،يمكن تركيبالحواجز المطاطيةواستبدالها بسهولة، مما يقلل من وقت التوقفعنالعملويحسن الكفاءة التشغيلية。

تُعد الاستدامةالبيئية مجالًا آخر تتألق فيه الحواجزالمطاطية。 المطاطمادةقابلة لإعادةالتدوير،ويمكن إعادةتدويرالشاشات المطاطيةالمستخدمة إلى منتجات جديدة، مما يقللمنالنفايات ويساهمفيالاستدامة البيئية。 علاوة على ذلك، فإن عمر الخدمةالطويلللشاشات المطاطيةيعنيعمليات استبدالأقلتكرارًا، ممايساهمأيضًافي

يساهماستخدامالشاشات المطاطيةأيضًافي السلامةفيالتطبيقات الصناعية。 تقللمقاومةالمادة للجروح والتمزقات من خطرالإصابةأثناء التركيبوالاستبدال。 علاوةعلىذلك،تساهم قدرةالشاشاتالمطاطية علىتقليلالضوضاءفي توفير بيئة عمل أكثر أمانًاعنطريقتقليل فقدانالسمعالناتجعن الضوضاء。

فيالختام، توفر الشاشات المطاطية مزاياعديدةفي التطبيقات الصناعية، ممايجعلهاخيارًا مفضلاً للعديد من الصناعات。 إنمتانتهاوأدائها وقدرتهاعلىتقليل الضوضاءومرونة التصميموالاستدامة البيئيةتجعلهامادة مثاليةلعملياتالفحص。 ومعاستمرارالصناعات في البحث عن طرق لتعزيز الكفاءةوالإنتاجية والاستدامة،فمن المرجح أن يصبح استخدام الشاشات المطاطيةأكثر انتشارًا。

橡胶筛分是各种工业应用中的关键组成部分,近年来获得了巨大的关注。这主要是由于其独特的性能以及与传统筛分材料相比具有的众多优势。橡胶筛网在采矿、建筑和回收等行业的使用彻底改变了这些行业的运作方式,提高了效率和生产率。

橡胶筛网最显着的优势之一是其耐用性。橡胶筛网以其弹性和承受恶劣条件的能力而闻名。它们耐磨损、耐切割和耐撕裂,非常适合重型应用。这种耐用性意味着更长的使用寿命,减少了筛网更换频率,从而降低了运营成本。

除了耐用性之外,橡胶筛网还具有卓越的性能。它们旨在提供高筛选效率,确保材料得到充分分离。这在采矿和建筑等行业尤其重要,因为分离过程的质量可以显着影响整体生产率。橡胶筛网还具有高承载能力,使其能够在不影响其性能的情况下处理大量物料。

橡胶筛网的另一个显着优势是其降噪能力。在工业环境中,噪音污染可能是一个重大问题,不仅影响工作环境,而且影响周围社区。橡胶筛网由于其固有的吸音特性,可以显着降低筛分过程中产生的噪音。这不仅改善了工作条件,还有助于行业遵守噪音法规。

橡胶屏还提供设计和定制方面的灵活性。它们可以制造成各种形状、尺寸和配置,以满足特定的应用要求。这种灵活性使各行业能够优化其筛选流程,提高效率和生产力。此外,橡胶筛网可以轻松安装和更换,减少停机时间并提高运营效率。

环境可持续性是橡胶筛网的另一个亮点领域。橡胶是一种可回收材料,用过的橡胶筛网可以回收制成新产品,减少浪费并促进环境可持续发展。此外,橡胶筛网的使用寿命长意味着更换频率较低,这也有助于减少对环境的影响。

橡胶筛网的使用也有助于提高工业应用的安全性。该材料的耐切割和耐撕裂性能降低了安装和更换过程中受伤的风险。此外,橡胶筛网的降噪能力可减少噪音引起的听力损失,从而有助于创造更安全的工作环境。

总而言之,橡胶筛网在工业应用中具有众多优势,使其成为许多行业的首选。其耐用性、性能、降噪能力、设计灵活性和环境可持续性使其成为筛选过程的理想材料。随着各行业不断寻求提高效率、生产力和可持续性的方法,橡胶筛网的使用可能会变得更加广泛。