What are the advantages of polyurethane screens compared with metal screens?

Increased Durability and Longevity

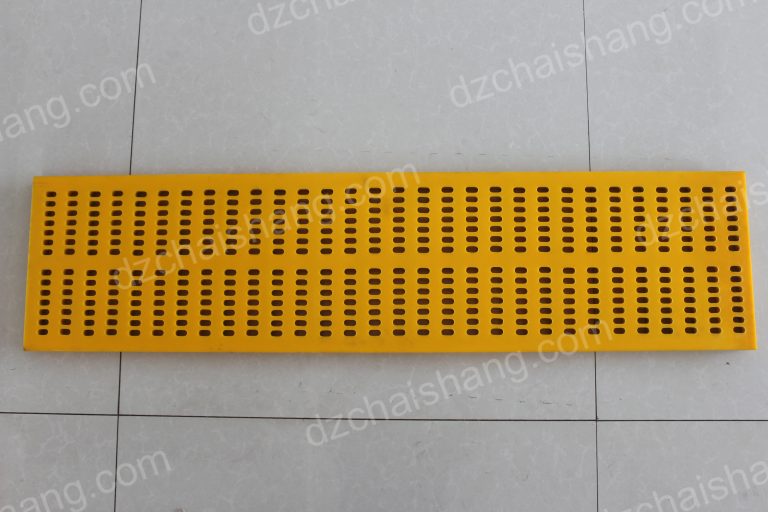

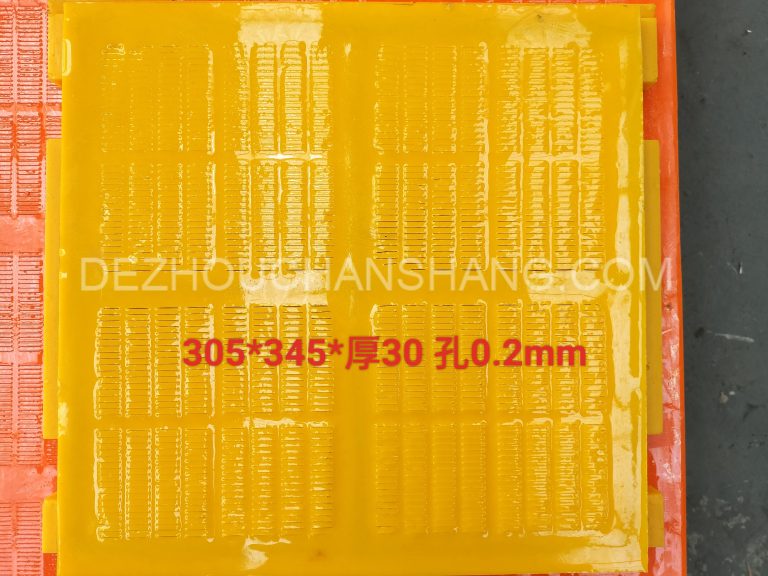

polyurethane screens have gained popularity in various industries due to their numerous advantages over traditional metal screens. One of the key benefits of polyurethane screens is their increased durability and longevity. In this section, we will explore why polyurethane screens outperform metal screens in terms of durability and how this can benefit businesses in the long run.

Polyurethane screens are known for their exceptional resistance to wear and tear. Unlike metal screens, which are prone to corrosion and abrasion, polyurethane screens are highly resistant to these damaging factors. This makes them ideal for applications in harsh environments, such as mining and aggregate industries, where metal screens often fail to withstand the demanding conditions.

The durability of polyurethane screens can be attributed to their unique material properties. Polyurethane is a synthetic material that exhibits excellent elasticity and flexibility. This allows the screens to absorb impact and resist deformation, even under heavy loads. In contrast, metal screens are rigid and more susceptible to bending or breaking when subjected to excessive pressure or impact.

Furthermore, polyurethane screens have a longer lifespan compared to metal screens. The resistance of polyurethane to corrosion and abrasion ensures that these screens can withstand prolonged use without deteriorating. This translates into reduced maintenance and replacement costs for businesses, as they do not have to frequently replace worn-out screens.

Another advantage of polyurethane screens is their ability to self-clean. The flexible nature of polyurethane allows the screens to vibrate, which helps prevent clogging and blinding. This is particularly beneficial in applications where the screening material tends to stick to the screen surface, such as in the processing of wet or sticky materials. Metal screens, on the other hand, are more prone to clogging, which can lead to reduced efficiency and increased downtime.

In addition to their durability and self-cleaning properties, polyurethane screens offer improved screening efficiency. The unique design of these screens, with their tapered openings and increased open area, allows for better material flow and increased throughput. This means that businesses can achieve higher production rates and better quality of screened materials with polyurethane screens compared to metal screens.

Furthermore, polyurethane screens are lighter in weight compared to metal screens. This makes them easier to handle and install, reducing the risk of workplace injuries and improving overall operational efficiency. The lightweight nature of polyurethane screens also contributes to their durability, as they are less prone to damage during handling and transportation.

In conclusion, polyurethane screens offer significant advantages over metal screens in terms of increased durability and longevity. Their resistance to wear and tear, self-cleaning properties, and improved screening efficiency make them a preferred choice for various industries. By investing in polyurethane screens, businesses can reduce maintenance and replacement costs, improve productivity, and ensure a longer lifespan for their screening equipment.