What are the advantages of polyurethane screens?

Improved durability and longevity

polyurethane screens have gained popularity in various industries due to their numerous advantages over traditional screens. One of the key benefits of polyurethane screens is their improved durability and longevity. In this article, we will explore why these screens are considered superior in terms of their ability to withstand wear and tear, and how they can contribute to cost savings in the long run.

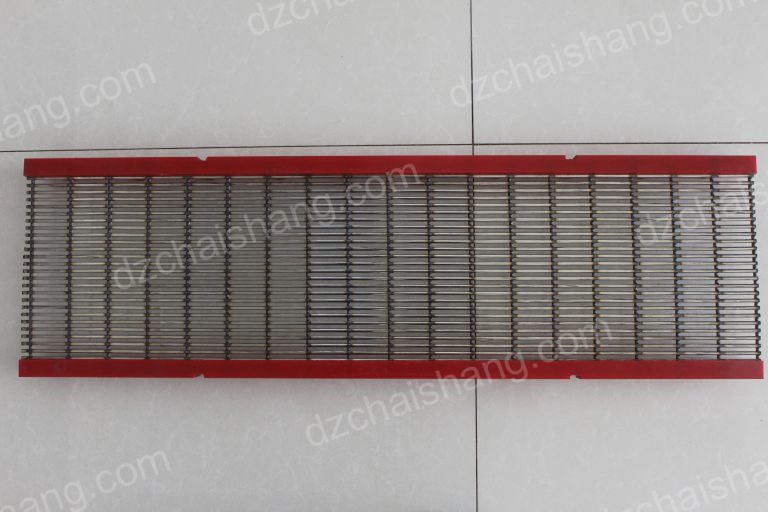

Polyurethane screens are known for their exceptional resistance to abrasion and impact. Unlike traditional screens made of steel or rubber, polyurethane screens are designed to withstand harsh conditions without succumbing to damage. This makes them ideal for industries that deal with abrasive materials or heavy-duty applications.

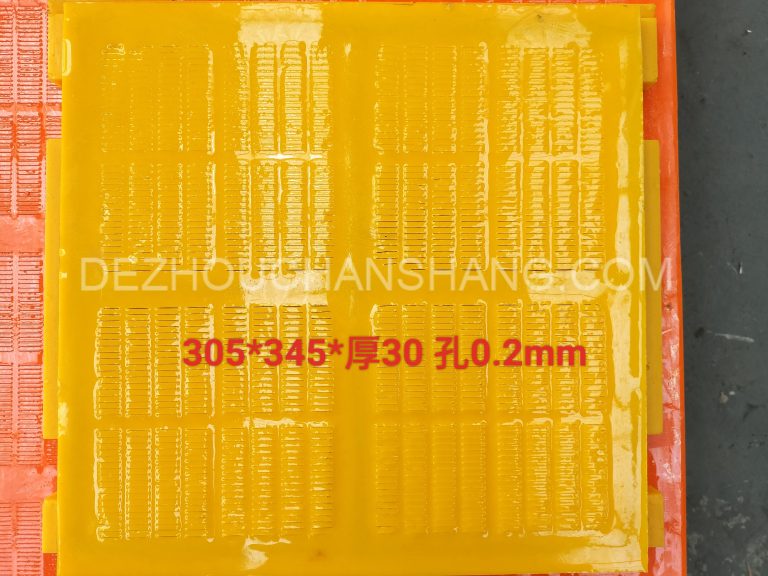

The secret behind the durability of polyurethane screens lies in their unique composition. These screens are made from a high-quality polyurethane material that is specifically engineered to resist wear and tear. The material is highly flexible, allowing it to absorb impact and prevent cracks or breakages. Additionally, polyurethane screens have a high tensile strength, which means they can withstand heavy loads without deforming or losing their shape.

Another advantage of polyurethane screens is their resistance to corrosion and chemical damage. Traditional screens made of steel are prone to rust and corrosion when exposed to moisture or chemicals. This not only affects their performance but also shortens their lifespan. In contrast, polyurethane screens are highly resistant to corrosion, making them suitable for applications where exposure to moisture or chemicals is common.

The longevity of polyurethane screens is further enhanced by their self-cleaning properties. These screens have a unique surface structure that prevents material build-up, such as blinding or pegging. This means that the screens remain clear and free from blockages, ensuring optimal performance and reducing downtime for cleaning and maintenance.

The improved durability and longevity of polyurethane screens translate into significant cost savings for businesses. By investing in these screens, companies can reduce their expenses on screen replacements and maintenance. The long lifespan of polyurethane screens means that they do not need to be replaced as frequently as traditional screens, resulting in lower replacement costs. Additionally, the self-cleaning properties of polyurethane screens reduce the need for regular cleaning and maintenance, saving both time and money.

Furthermore, the durability of polyurethane screens contributes to increased productivity. These screens can withstand heavy loads and harsh conditions, allowing businesses to operate at maximum efficiency without interruptions. The resistance to abrasion and impact ensures that the screens maintain their performance over time, providing consistent and reliable screening results.

In conclusion, polyurethane screens offer several advantages over traditional screens, particularly in terms of improved durability and longevity. Their resistance to wear and tear, corrosion, and chemical damage make them ideal for industries that deal with abrasive materials or harsh conditions. The self-cleaning properties of polyurethane screens further enhance their longevity and reduce maintenance requirements. By investing in polyurethane screens, businesses can enjoy cost savings in terms of reduced replacement and maintenance expenses, as well as increased productivity.