wholesaler shaker Polyurethane tension panel,jobbers Urethane tensioned sieve

Understanding the Benefits of Using Wholesaler Shaker polyurethane Tension Panel for Industrial Sieving

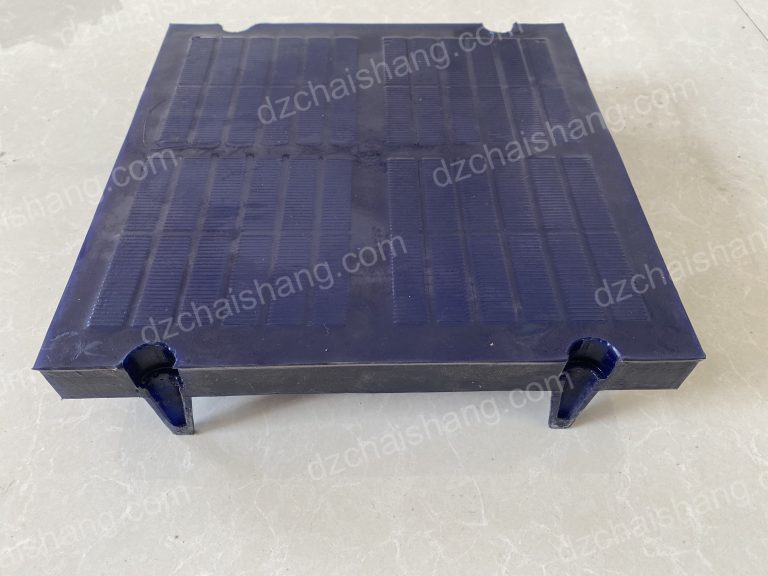

In the realm of industrial sieving, efficiency and durability are paramount. Every component of the sieving process plays a crucial role in ensuring optimal performance and productivity. One such component that has gained significant attention is the wholesaler shaker polyurethane tension panel. These panels, also known as jobbers urethane tensioned sieves, offer a range of benefits that make them indispensable in various industrial applications.

At the core of the wholesaler shaker polyurethane tension panel’s effectiveness is its material composition. Crafted from high-quality polyurethane, these panels boast exceptional resilience and longevity. Unlike traditional materials like steel or rubber, polyurethane offers a unique combination of flexibility and durability, making it ideal for demanding sieving environments.

One of the key advantages of using wholesaler shaker polyurethane tension panels is their superior wear resistance. Industrial sieving processes often involve abrasive materials that can quickly degrade conventional sieve components. However, polyurethane’s inherent resistance to abrasion ensures prolonged service life, resulting in cost savings and minimized downtime.

Furthermore, wholesaler shaker polyurethane tension panels excel in maintaining consistent tension across the sieve surface. This uniform tension is critical for achieving accurate particle separation and preventing oversize contaminants from bypassing the sieve. Unlike rigid materials that may develop weak points or deform over time, polyurethane maintains its structural integrity, ensuring reliable performance throughout its lifespan.

Another notable benefit of wholesaler shaker polyurethane tension panels is their enhanced screening efficiency. The smooth surface of polyurethane reduces friction, allowing particles to flow more freely across the sieve. This results in improved throughput and finer particle separation, ultimately enhancing overall process efficiency and product quality.

Additionally, polyurethane’s resistance to moisture and chemicals further extends the versatility of wholesaler shaker tension panels. Whether operating in wet or corrosive environments, these panels remain unaffected, maintaining their performance and integrity. This resistance to environmental factors not only prolongs the lifespan of the panels but also ensures consistent sieving performance regardless of operating conditions.

Moreover, the lightweight nature of polyurethane makes handling and installation of wholesaler shaker tension panels significantly easier compared to heavier materials like steel. This not only reduces labor costs but also enables quicker setup and maintenance procedures, minimizing downtime and maximizing productivity.

In terms of sustainability, wholesaler shaker polyurethane tension panels offer a greener alternative to traditional sieve components. Polyurethane is recyclable, meaning that at the end of its service life, it can be repurposed or processed into new materials, reducing environmental impact and promoting circular economy practices.

In conclusion, the benefits of using wholesaler shaker polyurethane tension panels for industrial sieving are undeniable. From exceptional wear resistance and consistent tension to enhanced screening efficiency and environmental sustainability, these panels offer a comprehensive solution for demanding sieving applications. By incorporating polyurethane tension panels into their operations, industrial facilities can achieve higher throughput, improved product quality, and reduced maintenance costs, ultimately driving greater overall efficiency and profitability.