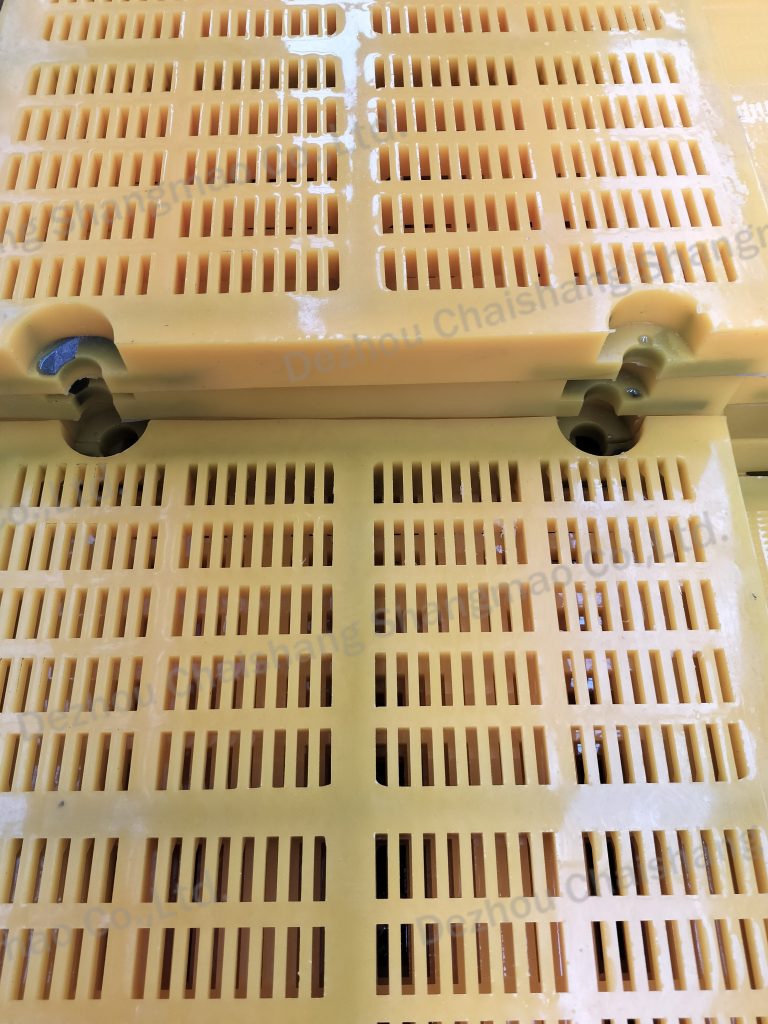

Manufacturer PU tension plate Mining,tension Urethane screenManufacture Ore

Benefits of Using Manufacturer PU Tension Plate in mining Operations

In the mining industry, efficiency and productivity are key factors in ensuring successful operations. One crucial component that plays a significant role in the mining process is the tension plate. Tension plates are used in mining operations to maintain the tension of screens, ensuring optimal screening performance. When it comes to tension plates, polyurethane (PU) tension plates are a popular choice among mining companies due to their durability, flexibility, and overall performance.

PU tension plates are manufactured using polyurethane, a synthetic material known for its exceptional strength and resilience. This makes PU tension plates highly durable and capable of withstanding the harsh conditions often encountered in mining operations. Unlike traditional tension plates made of metal or rubber, PU tension plates are resistant to abrasion, corrosion, and impact, making them ideal for use in demanding mining environments.

One of the key benefits of using PU tension plates in mining operations is their flexibility. PU tension plates can be easily molded into various shapes and sizes, allowing for customization to fit specific screening applications. This flexibility ensures that PU tension plates can be tailored to meet the unique requirements of different mining operations, resulting in improved screening efficiency and performance.

In addition to their durability and flexibility, PU tension plates offer superior performance compared to other types of tension plates. PU tension plates have a high tensile strength, which allows them to maintain the tension of screens effectively, ensuring consistent screening results. This results in reduced downtime and maintenance costs, as well as increased productivity and profitability for mining companies.

Furthermore, PU tension plates are lightweight, which makes them easy to handle and install. This not only saves time and labor during the installation process but also reduces the overall weight of the screening equipment, resulting in lower energy consumption and operating costs. Additionally, PU tension plates are non-conductive, making them safe to use in electrical screening applications.

Another advantage of using PU tension plates in mining operations is their resistance to wear and tear. PU tension plates have a long service life and require minimal maintenance, saving mining companies time and money in the long run. This durability ensures that PU tension plates can withstand the rigors of continuous use in mining operations without compromising their performance.

Overall, the benefits of using PU tension plates in mining operations are clear. From their durability and flexibility to their superior performance and resistance to wear and tear, PU tension plates offer numerous advantages that can help mining companies improve their screening efficiency and productivity. By investing in PU tension plates, mining companies can ensure reliable and consistent screening results, leading to increased profitability and success in the competitive mining industry.