How to choose high-quality polyurethane dewatering screen mesh?

How to Evaluate the Quality of polyurethane dewatering screen mesh

When selecting polyurethane screens, we can distinguish them from the following aspects:

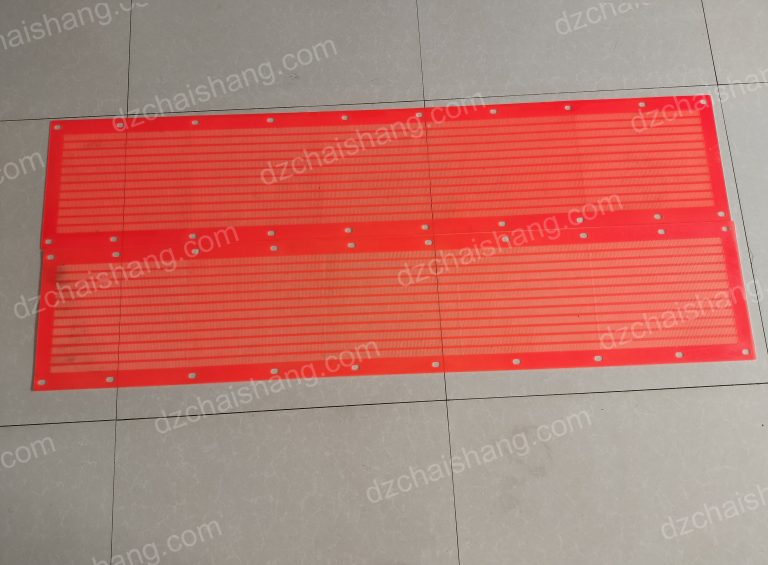

1. Depend on its appearance: Check whether the surface of the polyurethane mesh is exquisite, whether the mesh is flat, whether the color of the polyurethane mesh is pure, and whether there are broken strips, burrs, missing materials, mixed materials, tight seams, etc.

2. Look at the opening rate of the product: Generally, the opening rate is the most direct factor affecting screening efficiency: the more holes the polyurethane screen has, the higher the opening rate, and the higher the screening efficiency and output will be.

What to Look for When Choosing Polyurethane dewatering screen mesh for Your Application

3. Look at the connection of the product: the connection method of the polyurethane screen directly affects the screening efficiency. The polyurethane screen developed by our factory has a screen with an automatic connecting device. The connection is simple and time-saving, and the disassembly and assembly are more convenient. It is convenient to shorten the initial installation time and the partial screen replacement time during use, thereby improving production efficiency. The polyurethane screens are required to be tightly connected to each other without leaking minerals to ensure the quality.

4. Check whether the sieve holes are uniform: The sieve holes of high-quality polyurethane screens are uniform and in compliance with standards, and the tolerance range is small. Unscrupulous merchants often miss this link whether the sieve holes meet the standards. They are most likely to make loopholes in the details of the product. Everyone should pay attention when observing. Generally, unscrupulous merchants will always make mistakes in more subtle work. question.

5. High-quality polyurethane screens must have moderate rigidity and softness: In actual production, polyurethane screens are required to have strong elasticity to ensure that they do not collapse during production; polyurethane screens must also have a certain degree of toughness to ensure that the screens are not brittle.

Regarding this point, some unscrupulous merchants may not be able to manufacture it because it requires high costs and technical capabilities, and it is also a relatively detailed and patient job. Therefore, you can rely on this to know the quality when purchasing. What exactly does a polyurethane screen look like