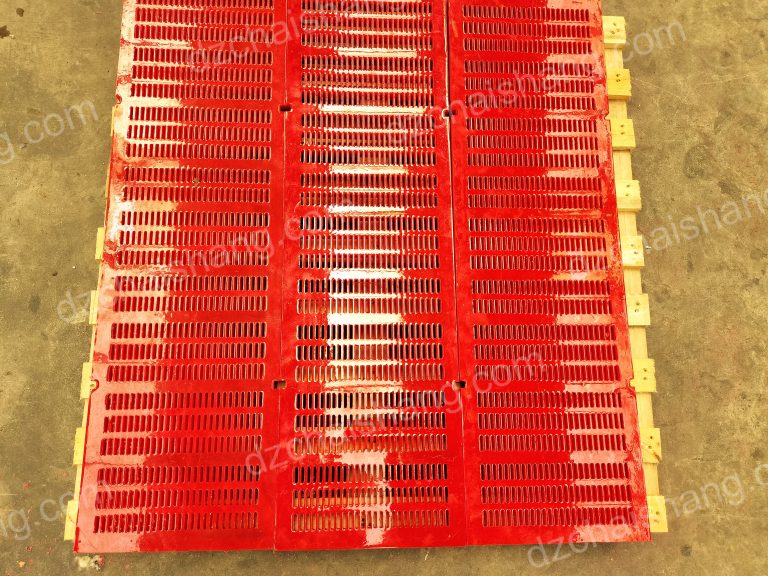

Lưới polyurethane cho các ứng dụng sàng lọc công nghiệp

فوائد استخدام شبكة البولي يوريثان لتطبيقات الفحص الصناعي

شبكة البولي يوريثان خيارًا شائعًا لتطبيقات الفحص الصناعي بسبب فوائدها العديدة. توفر هذه المادة متعددة الاستخدامات مجموعة من المزايا التي تجعلها مثالية للاستخدام في مجموعة متنوعة من الصناعات ، من التعدين والتجميع إلى معالجة الأغذية والأدوية. في هذه المقالة ، سوف نستكشف بعض الفوائد الرئيسية لاستخدام شبكة البولي يوريثان لتطبيقات الفحص الصناعي. على عكس الشاشات المعدنية التقليدية ، فإن شبكة البولي يوريثان مقاومة للتآكل والتآكل والارتداء ، مما يجعلها مثالية للاستخدام في البيئات الصناعية القاسية. تضمن هذه المتانة أن شبكة البولي يوريثان يمكنها تحمل قسوة الاستخدام المستمر دون الحاجة إلى استبدال متكرر ، وتوفير الوقت والمال على المدى الطويل. بالإضافة إلى متانتها ، فإن شبكة البولي يوريثان مرنة للغاية. تتيح هذه المرونة للشبكة أن تتوافق مع شكل معدات الفحص ، مما يضمن تناسب ضيق وأداء الفحص الأمثل. إن قدرة شبكة البولي يوريثان على الثني وتمتد دون فقدان شكلها تجعلها مثالية للاستخدام في شاشات الاهتزاز وأنواع أخرى من معدات الفحص التي تتطلب درجة عالية من المرونة.

فائدة رئيسية أخرى لشبكة البولي يوريثان هي مقاومتها للانسداد. يسمح التصميم المفتوح للشبكة بتدفق المواد الفعال ، مما يمنع التراكم والانسداد الذي يمكن أن يقلل من كفاءة الفحص. تضمن هذه المقاومة للانسداد أن شبكة البولي يوريثان تحافظ على أداء الفحص مع مرور الوقت ، حتى عند فحص المواد اللزجة أو التي يصعب على الشاشة. تجعل الطبيعة الخفيفة الوزن لشبكة البولي يوريثان من السهل التعامل والتركيب ، وتقليل وقت التوقف أثناء تغييرات الشاشة. بالإضافة إلى ذلك ، من السهل تنظيف شبكة البولي يوريثان ، والتي تتطلب فقط غسلًا بسيطًا بالماء أو منظف معتدل لإزالة التراكم والحفاظ على أداء الفحص الأمثل. تسمح الفتحات الدقيقة للشبكة بالفصل الدقيق للمواد ، مما يضمن أن الجزيئات المطلوبة فقط تمر أثناء إزالة الجسيمات الضخمة بكفاءة. تؤدي كفاءة الفحص العالية هذه إلى تحسين جودة المنتج وتقليل النفايات ، مما يجعل شبكة البولي يوريثان خيارًا مثاليًا للصناعات التي تتطلب فحصًا دقيقًا.

في الختام ، توفر شبكة البولي يوريثان مجموعة من الفوائد التي تجعلها خيارًا مثاليًا لتطبيقات الفحص الصناعي. من المتانة والمرونة إلى مقاومتها للانسداد وسهولة التثبيت والصيانة ، توفر شبكة البولي يوريثان حلاً موثوقًا وفعالًا لمجموعة واسعة من الصناعات. سواء تم استخدامه في التعدين أو الإجمالي أو معالجة الأغذية أو الأدوية ، فإن شبكة البولي يوريثان توفر المتانة والمرونة والكفاءة اللازمة لضمان أداء الفحص الأمثل.