聚氨酯筛网,振动筛网供应商,高频筛

استكشاففوائد واستخدامات شبكةشاشة البولي يوريثين

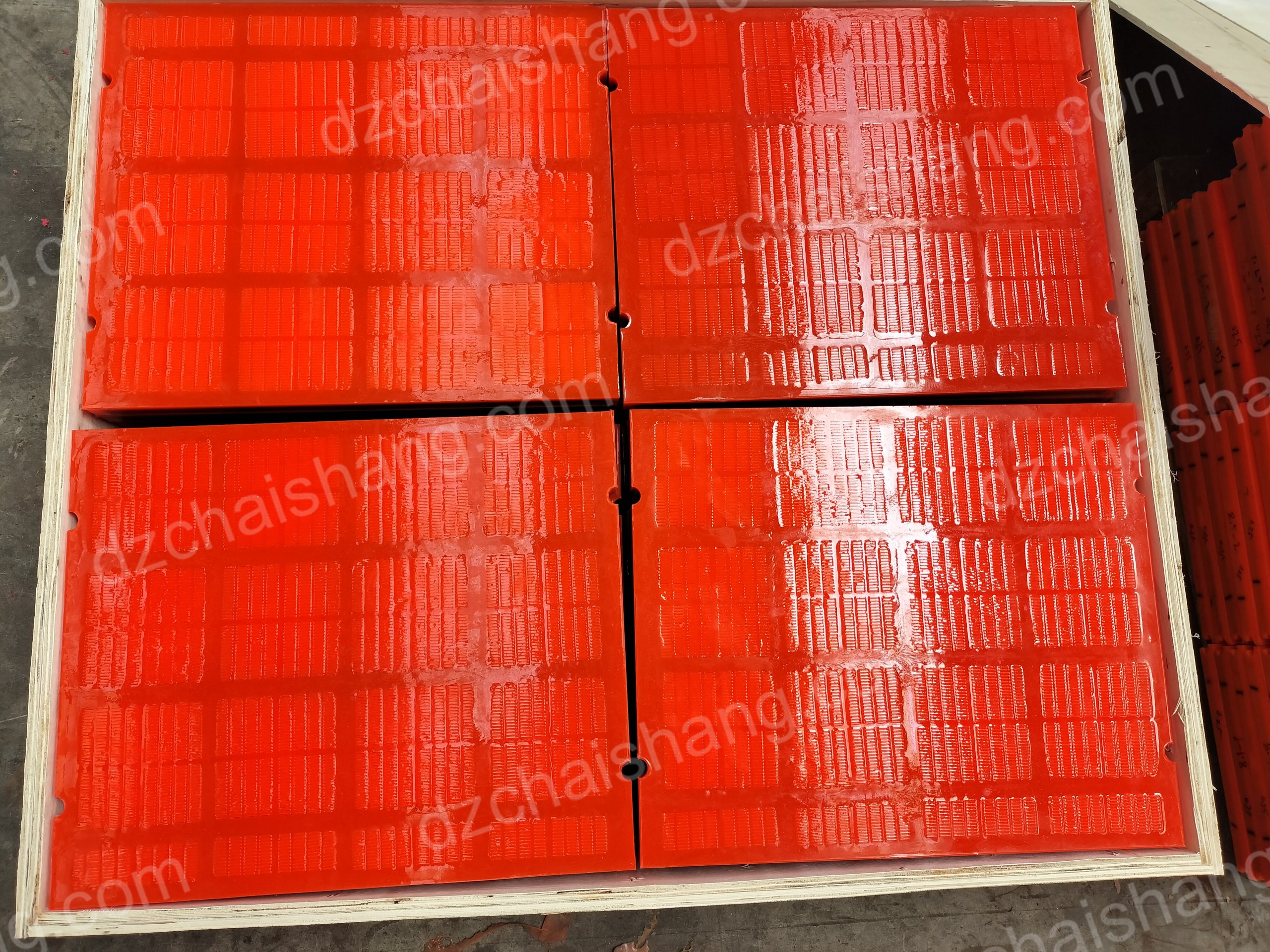

شبكةالغربلةمنالبولي يوريثين، المنتج الذي أحدث ثورة في صناعات التعدينوالتجميع،هي سلعةمطلوبةللغايةبين موردي شبكات الغربلة الهزازة。 هذا المنتج المبتكر، المعروفبمتانتهوتعدد استخداماته،فعالبشكل خاص عند استخدامه في الشاشات عالية التردد。

شبكةالشاشةمن البولي يوريثين هي نوع منموادالغربلة المصنوعةمنالبولي يوريثين،وهونوعمن البوليمرالمعروف بمتانتهالاستثنائية ومقاومةالبلى。 وهذايجعلهاخيارًا مثاليًاللاستخدامفي الصناعات التي يتم فيها نقلالموادومعالجتها باستمرار، مثلالتعدين والإنتاج الكلي。

إحدى الفوائدالرئيسية لشبكةشاشةالبولي يوريثينهيمقاومتها العاليةللتآكل。 علىعكسالأنواعالأخرى من مواد شبكات الشاشة، فإنمادةالبولي يوريثينقادرةعلىتحمل التآكلالمستمر والتأثيرالذييأتيمع معالجةالموادالصلبة。 وهذايعنيأنهايمكنأن تدوم لفترة أطول بكثير منالأنواعالأخرىمن شبكات الشاشات، مما يقللالحاجةإلى الاستبدالاتالمتكررة وبالتالي توفير الوقت والمالللشركات。

الميزة الرئيسيةالأخرى لشبكات الشاشات المصنوعةمنالبولي يوريثينهيمرونتها。 علىعكسشبكةالشاشة المعدنية، التي يمكن أن تكونصلبةوعرضةللتشقق تحت الضغط، فإن البولي يوريثينمرنوقادرعلى امتصاصالصدماتدونأن ينكسر。 وهذايجعلهافعالةبشكل خاصللاستخدامفي الشاشات عالية التردد، حيث يمكن للحركة السريعةللموادأنتضع قدرًاكبيرًامنالضغط علىشبكة الشاشة。

بالإضافةإلى متانتهاومرونتها، توفرشبكةالشاشة المصنوعةمنالبولي يوريثينأيضًاأداءً فائقًامنحيثمنكفاءة الفرز。 يسمح سطحهالأملس وفتحاتهالدقيقة بالتحجيمالدقيق للمواد وفصلها، مما يضمنتلبيةالمنتج النهائي للمواصفات المطلوبة。 علاوةعلىذلك،فإن مقاومتهاللعمى والانسداد تعني أنها تستطيعالحفاظعلى كفاءةالفحصحتىفي الظروفالصعبة。

لقد أدرك موردو شبكات الغربلةالاهتزازية فوائد البولي يوريثين وبدأوافيتقديمهكخيار قياسيلعملائهم。 يتزايد الطلبعلىهذه المادة، حيث تدرك المزيد والمزيد من الشركات المزاياالتي تقدمهامقارنةبمواد شبكات الشاشة التقليدية。

وقد استفادت الشاشات عالية التردد، على وجه الخصوص، بشكل كبير من استخدامشبكةشاشات البولييوريثين。 هذهالغرابيل،التي تعملبسرعاتعاليةلفصل المواد على أساس الحجم، تتطلبشبكةغربال يمكنهاتحمل الاهتزازات الشديدة دون أن تنكسر أو تفقد شكلها。 يعتبرالبولييوريثين، بمزيجهمنالمتانة والمرونة، مناسبًا بشكلمثاليلهذهالمهمة。

في الختام، توفر شبكة شاشة البولي يوريثين مجموعة من الفوائد التي تجعلهاخيارًاممتازًا للاستخدامفيصناعات التعدينوالتجميع。 إنمقاومتهاالعالية للتآكل، والمرونة، وكفاءةالفحصالفائقة تجعلها بديلاً فعالاً منحيثالتكلفةوعالي الأداءلموادشبكة الشاشةالتقليدية。 معاستمرارمورديشبكات الغربلةالاهتزازيةفي تقديمهذاالمنتج المبتكر، ومع اعتماد المزيد منالصناعات لتكنولوجياالغربلة عاليةالتردد،من المقررأنيزداد استخدامشبكاتالغربال المصنوعةمنالبولي يوريثين。 فوائدهواضحة، وتطبيقاتهالمحتملة واسعة، مما يجعله منتجًايستحقالمشاهدة فيالسنوات القادمة.

اختيار الموردينالمناسبين لشبكات الغربلة الاهتزازية:دليلشامل

يعداختيارالموردين المناسبينلشبكات الغربلةالاهتزازية قرارًاحاسمًايمكنأن يؤثربشكلكبيرعلى كفاءةوفعاليةعمليات الفحصالخاصةبك。 توفرهذهالمقالة دليلاً شاملاً لمساعدتكعلىاتخاذ قرارمستنير。

تعد شبكة شاشة البولي يوريثينخيارًاشائعًا للعديد منالصناعات نظرًالمتانتها ومرونتهاوقدرتهاعلى تحملالظروفالقاسية。 يتماستخدامهعلىنطاق واسعفيالتعدين واستغلالالمحاجر وغيرهامنالتطبيقات الثقيلةحيثمنالمتوقع حدوثتآكلكبير。 تُعرف شبكة شاشة البولي يوريثينبمقاومتها العاليةللتآكل والتآكلوالتأثير،مما يجعلهاخيارًامثاليًا لفحصالموادذات الأحجاموالأشكال المختلفة。

ومعذلك،لا يتم إنشاء جميع شبكات شاشة البولي يوريثين بشكلمتساوٍ。 يمكن أن تختلف جودة الشبكةبشكلكبير اعتمادًاعلىالشركة المصنعة。 لذلك، من الضروري اختيار مورد معروف بإنتاج منتجات عالية الجودة。 ابحث عن الموردين الذين لديهمسجلحافلفي الصناعةوالمعروفين بالتزامهمبالجودة ورضاالعملاء。

أحدالعواملالرئيسية التي يجبمراعاتهاعند اختيارموردشبكة الغربلةالاهتزازيةهي عمليةالتصنيعالخاصة بهم。 سيستخدمالموردذو السمعةالطيبةتقنيات التصنيعالمتقدمة لضمانمتانةوأداء منتجاته。 يجبعليهمأيضًا استخدامموادخامعالية الجودةلضمانطولعمر شبكةالشاشة。

فهموظائفومزايا الشاشات عالية التردد

الغرابيلعالية التردد، التي تستخدم غالبًافيصناعات التعدينومعالجة المعادن، هي نوع من آلات الغربلةالميكانيكية التي تستخدمآلية الاهتزازلفصلوتصنيف الجسيماتوفقًاللحجم。 يتم تحقيق ذلك من خلال استخدامشبكةشاشةمن مادة البولي يوريثين، وهي مادة متينة ومرنة، ممايجعلهامثاليةلهذا النوعمنالتطبيقات。

تعد شبكة شاشة البولي يوريثينمكونًامهمًا للشاشةعاليةالتردد。 لقدتمتصميمهليتحمل قسوةعمليةالغربلة، والتي تتضمن اهتزازًا مستمرًاوحركةكمية كبيرةمنالمواد。 الشبكةمصنوعةمنمادة البولي يوريثين، وهو نوعمنالبوليمر المعروفبمقاومته الممتازةللتآكلوعمر الخدمةالطويل。 وهذايجعلهامادة مثاليةللاستخدامفي الشاشات عالية التردد، والتي يجب أن تكون قادرة علىتحملالتآكل المستمرلعملية الغربلة。

تمتصميمشبكة شاشة البولي يوريثين أيضًالتوفيرمستوى عالٍ من الدقة في عملية الغربلة 。 الشبكةمتوفرةفي مجموعةمتنوعةمن الأحجام، مما يسمح لها بفصلالجزيئاتذات الأحجامالمختلفةبدقة。 تعد هذه ميزة مهمة في العديد من الصناعات، حيث يمكن أن يكون لحجم الجزيئات التي تتم معالجتهاتأثيركبير علىجودةالمنتج النهائي。

هناكالعديدمن موردي شبكات الغربلة الاهتزازيةفيالسوق، ويقدمونمجموعةمن المنتجات التي تناسبهم احتياجاتمختلفة。 عند اختيار المورد، من المهممراعاةعواملمثل جودةالشبكةوموثوقية الموردوتكلفةالمنتج。 سيتمكنالموردالجيدمن توفير منتج عالي الجودة يلبي الاحتياجات المحددةللتطبيق،بسعر تنافسي في السوق。

توفر الشاشات عالية التردد عددًامنالمزايا مقارنةبطرقالفحص التقليدية。 إحدىالمزاياالرئيسية هي قدرتها على معالجة كمية كبيرة من المواد في فترةزمنيةقصيرة。 ويرجعذلكإلىالتردد العالي للاهتزاز، والذي يسمح للشاشة بتحريكالمزيدمن المواد عبر الشبكة في فترةزمنيةمعينة。 يمكن أن يؤدي ذلك إلى زيادةكفاءةعملية الغربلةبشكلكبير،مما يجعلها حلاً فعالاً من حيث التكلفة للعديد من التطبيقات.

الميزة الأخرىللغرابيلعالية التردد هي قدرتهاعلى فصلالجسيماتالدقيقة بدقة。 قدتواجهطرقالفحص التقليديةصعوبةفيفصل الجزيئاتالدقيقة بدقة، مما قد يؤدي إلى منتجنهائيأقلجودة。 ومع ذلك، فإن الاهتزاز عالي التردد لهذه الشاشات يسمح لهابفصل هذهالجزيئاتالدقيقة بشكل فعال، مما يؤدي إلى منتجعاليالجودة。 。 إنمتانتهاومرونتها وقدرتهاعلىتحمل التآكلالمستمرتجعلها خيارًامثاليًاللعديد منالصناعات。 معتوفرمجموعةمتنوعة من موردي شبكات الغربلة الاهتزازية،منالمهم اختيار مورد موثوق يمكنهتوفيرمنتجعالي الجودةيلبي الاحتياجات المحددة للتطبيق。 إنمزاياالشاشاتعالية التردد، بما في ذلك قدرتهاعلىمعالجة كميات كبيرة من المواد بسرعةوفصلالجسيمات الدقيقة بدقة، تجعلها حلاً فعالاً من حيث التكلفةللعديدمن التطبيقات.

高频筛,常用于采矿和选矿行业,是一种机械筛分机,利用振动机构来分离和根据大小对颗粒进行分类。这是通过使用聚氨酯筛网实现的,这种材料既耐用又灵活,非常适合此类应用。

聚氨酯筛网是高频筛网的关键组件。它的设计能够承受筛选过程的严酷,其中包括持续的振动和大量材料的移动。网格由聚氨酯制成,聚氨酯是一种聚合物,以其优异的耐磨性和较长的使用寿命而闻名。这使其成为高频筛的理想材料,高频筛需要能够承受筛分过程中的持续磨损。

聚氨酯筛网的设计还可以在筛选过程中提供高精度。筛网有多种尺寸可供选择,使其能够准确分离不同尺寸的颗粒。这是许多行业的一个关键特征,其中被处理的颗粒尺寸会对最终产品的质量产生重大影响。

市场上有许多振动筛网供应商,提供一系列适合的产品不同的需求。选择供应商时,重要的是要考虑网格的质量、供应商的可靠性以及产品的成本等因素。优秀的供应商将能够以具有市场竞争力的价格提供满足特定应用需求的高质量产品。

高频筛与传统筛分方法相比具有许多优势。主要优点之一是它们能够在短时间内处理大量材料。这是由于振动的频率很高,这使得筛子可以在给定的时间内在筛网上移动更多的材料。这可以显着提高筛分过程的效率,使其成为许多应用的经济高效的解决方案。

高频筛的另一个优点是它们能够精确分离细颗粒。传统的筛选方法很难准确分离细颗粒,从而导致最终产品质量较低。然而,这些筛子的高频振动使它们能够有效地分离这些细颗粒,从而产生更高质量的产品。

总而言之,高频筛子及其聚氨酯筛网提供了一种高效、准确的颗粒分离方法。它们的耐用性、灵活性和承受持续磨损的能力使它们成为许多行业的理想选择。有多种振动筛网供应商可供选择,选择一家可靠的供应商非常重要,该供应商可以提供满足特定应用需求的高质量产品。高频筛的优点,包括快速处理大量材料并准确分离细颗粒的能力,使其成为许多应用的经济高效的解决方案。