polyurethane vibrating screen

The Benefits of Using polyurethane Vibrating screens

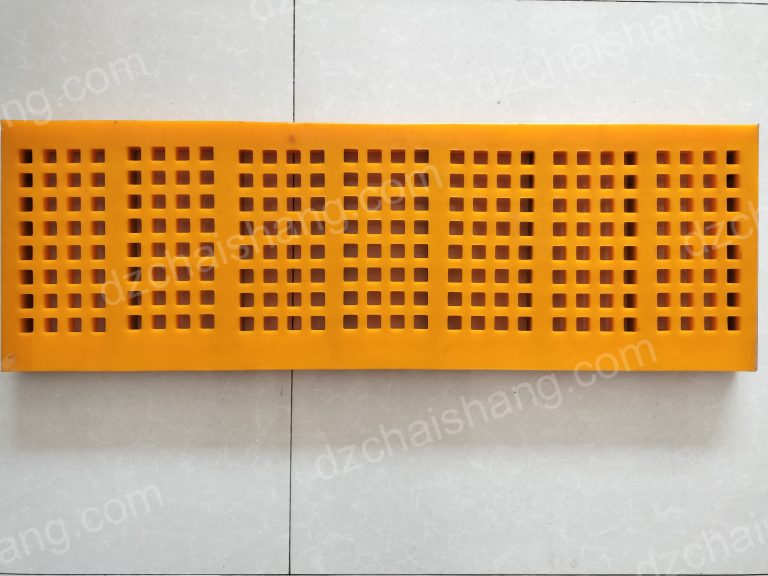

Polyurethane vibrating screens have become increasingly popular in various industries due to their numerous benefits. These screens are made from a unique material called polyurethane, which offers several advantages over traditional vibrating screens made from other materials such as steel or rubber.

One of the main benefits of using polyurethane vibrating screens is their durability. Polyurethane is a highly durable material that can withstand harsh conditions and heavy use. Unlike steel screens, which can rust and corrode over time, polyurethane screens are resistant to corrosion, making them ideal for use in industries where exposure to moisture or chemicals is common.

Another advantage of polyurethane vibrating screens is their flexibility. Polyurethane is a flexible material that can be molded into various shapes and sizes, allowing for customization to meet specific requirements. This flexibility also makes polyurethane screens more resistant to damage from impact or vibration, ensuring a longer lifespan compared to other materials.

Polyurethane vibrating screens are also known for their high abrasion resistance. The material is designed to withstand constant friction and wear, making it ideal for applications where the screen is subjected to heavy loads or abrasive materials. This abrasion resistance ensures that the screen maintains its effectiveness and efficiency over time, reducing the need for frequent replacements and saving costs in the long run.

In addition to their durability and flexibility, polyurethane vibrating screens offer excellent screening efficiency. The material has a high open area, which allows for efficient passage of materials through the screen. This results in improved screening performance and increased productivity, as more materials can be processed in a shorter amount of time.

Polyurethane vibrating screens also provide superior noise reduction compared to other materials. The flexible nature of polyurethane absorbs vibrations and reduces noise levels, creating a quieter working environment. This is particularly beneficial in industries where noise pollution is a concern, such as mining or construction sites.

Furthermore, polyurethane vibrating screens are easy to install and maintain. The lightweight nature of the material makes it easier to handle and install, reducing installation time and costs. Additionally, polyurethane screens are self-cleaning, meaning that they do not require frequent cleaning or maintenance. This saves time and effort, allowing for more efficient operations.

Lastly, polyurethane vibrating screens are environmentally friendly. The material is non-toxic and does not release harmful chemicals or pollutants into the environment. This makes polyurethane screens a sustainable choice for industries looking to reduce their environmental impact.

In conclusion, polyurethane vibrating screens offer numerous benefits over traditional screens made from other materials. Their durability, flexibility, abrasion resistance, screening efficiency, noise reduction, ease of installation and maintenance, and environmental friendliness make them an excellent choice for various industries. By investing in polyurethane vibrating screens, businesses can improve their operations, reduce costs, and contribute to a more sustainable future.