Polyurethane screen plate production technology and equipment

How polyurethane screen plate Production Technology and Equipment Can Improve Efficiency and Productivity

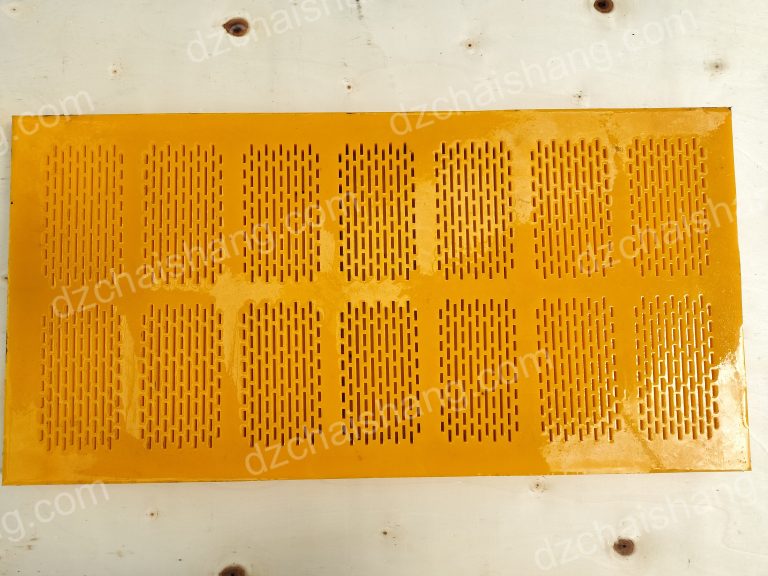

The polyurethane screen plate is made of high-quality polyurethane as the basic material. Because the polyurethane material is not only elastic, but also has excellent properties such as wear resistance, oil resistance, acid and alkali resistance, ozone resistance, and aging resistance. The polyurethane screen plate made of this material is used in various applications. Excellent performance in the work environment.

The Benefits of Investing in Advanced Polyurethane Screen Plate Production Technology and Equipment

However, if the performance of polyurethane screen plates is to be richer and more perfect, it cannot only rely on the choice of materials, but also requires excellent manufacturing technology. For the processing of polyurethane screen plates, every processing step is very critical and important. , every link is indispensable, the most important of which is the pouring of polyurethane screen plate.

At present, there are three common methods for pouring polyurethane screen plates, namely mechanical pouring, manual pouring and vulcanization.

Mechanical pouring requires the use of a pouring machine. Tank A in the pouring machine is the prepolymer and tank B is the chain extender. When ready, start the heating system and set the heating temperature so that A and B reach the required temperature at the same time, and then By observing the rotation speed and displacement of the metering pump, we mainly observe the mixing ratio of the two. After reaching the ratio, the pouring process is started. At that time, the AB material is mixed evenly at high speed in the mixing chamber, and then pouring can begin. The advantage of the mechanical pouring method of polyurethane screen plates is that the proportioning accuracy is high, the metering is stable, the mixing is uniform and it is not easy to generate bubbles.

The manual pouring method of polyurethane screen plates is to mix the measured prepolymer and chain extender evenly under certain conditions, then inject the mixture into the mold, and heat and vulcanize for one hour to demould. The characteristics of manual pouring and processing of polyurethane screen plates are low cost investment, flexible and easy operation, and is suitable for small and medium-sized production enterprises.

The vulcanization and maturation of the polyurethane screen plate refers to the vulcanization and molding process of the product in the mold. The temperature selection during this process can be increased without destroying the chemical structure of the polyurethane screen plate, which is conducive to accelerating chain extension and cross-linking. reaction, shortening the demoulding time and improving the production efficiency and utilization of polyurethane screen plates.