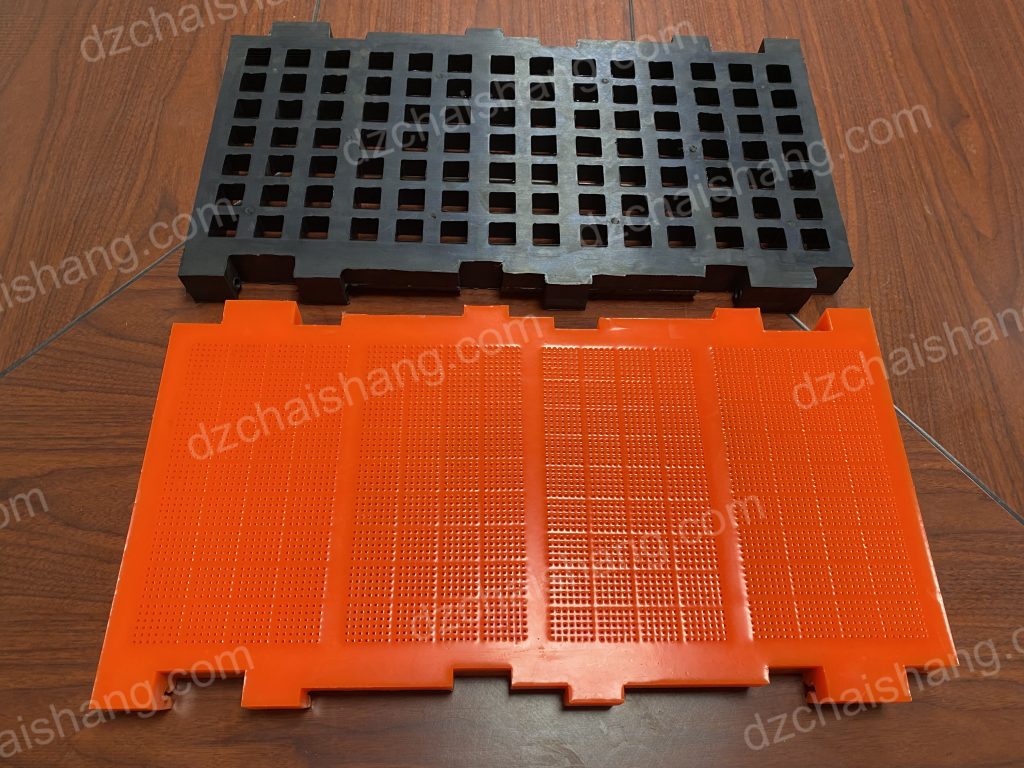

Factory Rubber modular Deck Dewatering,direct sales vibrator Rubber mesh Aggregate

How Factory Rubber Modular Deck Dewatering Can Improve Your Aggregate Production

Factory rubber modular deck dewatering is a process used in aggregate production to improve the quality of the end product. This process involves the use of a rubber-coated conveyor belt to separate water from the aggregate material. The rubber-coated conveyor belt is designed to allow water to pass through it while trapping the aggregate material on the surface. This process helps to reduce the moisture content of the aggregate material, resulting in a higher quality product.

The use of factory rubber modular deck dewatering can improve the quality of the aggregate material in several ways. First, it can reduce the amount of water that is present in the material, which can help to reduce the amount of dust that is created during the production process. This can help to reduce the amount of airborne dust particles that are created, which can help to improve air quality in the area. Additionally, the reduced moisture content of the material can help to reduce the amount of time that is needed to dry the material, which can help to reduce energy costs associated with the drying process.

The use of factory rubber modular deck dewatering can also help to improve the overall efficiency of the production process. By reducing the amount of water that is present in the material, the conveyor belt can move the material more quickly, which can help to reduce the amount of time that is needed to complete the production process. Additionally, the reduced moisture content of the material can help to reduce the amount of energy that is needed to move the material, which can help to reduce energy costs associated with the production process.

Overall, factory rubber modular deck dewatering can help to improve the quality of the aggregate material and the efficiency of the production process. By reducing the amount of water that is present in the material, the conveyor belt can move the material more quickly, which can help to reduce the amount of time that is needed to complete the production process. Additionally, the reduced moisture content of the material can help to reduce the amount of energy that is needed to move the material, which can help to reduce energy costs associated with the production process.

The Benefits of Direct Sales Vibrator Rubber mesh Aggregate for Your Business

Direct sales vibrator rubber mesh aggregate is a great option for businesses looking to increase their efficiency and productivity. This type of aggregate is designed to be used in a variety of applications, including sorting, sizing, and separating materials. It is also used to reduce the amount of time and energy required to process materials.

The use of direct sales vibrator rubber mesh aggregate can provide a number of benefits to businesses. First, it can reduce the amount of time and energy required to process materials. This can help to reduce costs associated with labor and energy consumption. Additionally, it can help to improve the quality of the materials being processed. This can lead to improved product quality and increased customer satisfaction.

Another benefit of using direct sales vibrator rubber mesh aggregate is that it can help to reduce the amount of dust and debris that is created during the processing of materials. This can help to reduce the amount of time and energy required to clean up the area after the process is complete. Additionally, it can help to reduce the amount of noise created during the process. This can help to improve the working environment for employees and customers alike.

Finally, direct sales vibrator rubber mesh aggregate can help to improve the safety of the workplace. This type of aggregate is designed to be used in a variety of applications, including sorting, sizing, and separating materials. This can help to reduce the risk of injury or accidents that can occur when handling materials. Additionally, it can help to reduce the amount of dust and debris that is created during the process. This can help to improve the overall safety of the workplace.

Overall, direct sales vibrator rubber mesh aggregate can provide a number of benefits to businesses. It can help to reduce the amount of time and energy required to process materials, improve the quality of the materials being processed, reduce the amount of dust and debris created during the process, and improve the safety of the workplace. All of these benefits can help to improve the efficiency and productivity of businesses.