Màn hình rung màn hình căng chất lượng cao, bảng màn hình móc căng

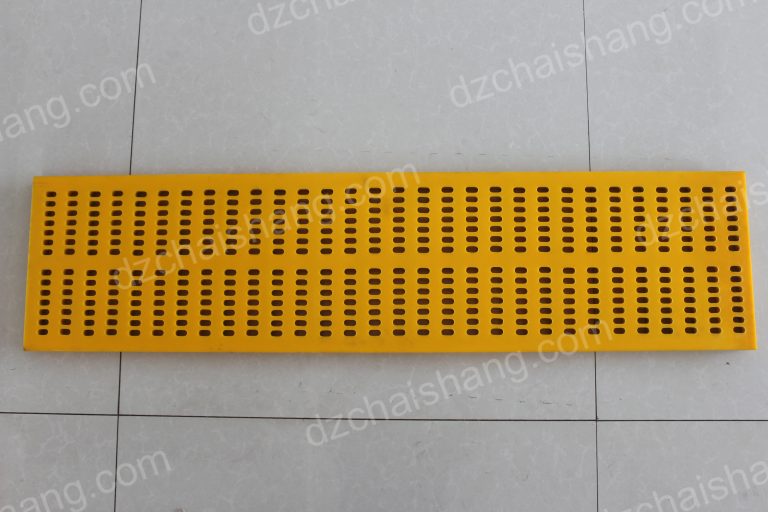

بالإضافةإلىذلك،فإن المواد المستخدمة في صناعةهذهالألواح=u0639ادة ماتكونعبارةعنأسلاك عاليةالقوةومقاومة للتآكلأومنمادة البولييوريثين。 تعتبرهذهالمواحاسمة في إطالة عمر لو=== الشاشة، =تى في ظل ظروف التشغيلالقاسية。 لاتقللهذهالمتانةمن = = = 2 00b20 0b

2 00b20 0b فترةأطول。 علاوةعلىذلك،يمكن لهذهالموادالقويةأن تتحملالأ===u0645ال المختلفةوالمواد الكاشطة، ممايجعلها مناسبةلمجموعةواسعة منالتطبيقات。

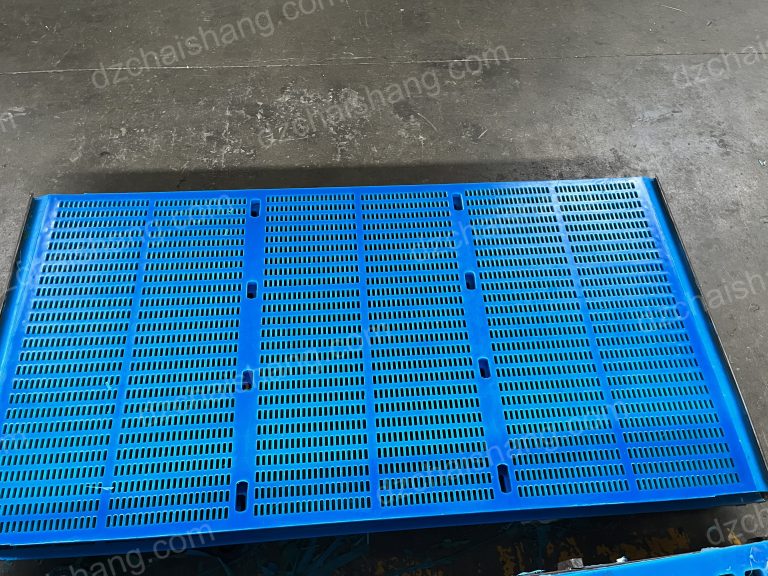

بالانتقالإلىلوح=u0627ت الشاشة الخطافية، فهي مشهورةبسهولةالتركيب وتعددالاستخدامات。 تعملالخطافات الموجودةعلى===u0648افهذه اللوحات على تسهيل التث بيت السريعوالفصل عنإطارالشاشة الاهتزازية。 تعتبرهذهالميزةمفيدة بشكلخاصفيالصناعات التي تحتاج إلى تغيير الشاشات بشكلمتكرر لاستيعابأنواعمختلفة منالموادأوأحجام الجسيمات。 تساعد قابليةالتبادل السريععلىتقليلوقت التوقفعنالعملوزيادة

علاوةعلىذلك،ي

بالإضافةإلىذلك،فإن المواد المستخدمة في صناعةهذهالألواح=u0639ادة ماتكونعبارةعنأسلاك عاليةالقوةومقاومة للتآكلأومنمادة البولييوريثين。 تعتبرهذهالموادحاسمة في إطالة عمر لو=== الشاشة، =تى في ظل ظروف التشغيلالقاسية。 لاتقللهذهالمتانةمن = = = 2 00b20 0b

2 00b20 0b فترةأطول。 علاوةعلىذلك،يمكن لهذهالموادالقويةأن تتحملالأ===u0645ال المختلفةوالمواد الكاشطة، ممايجعلها مناسبةلمجموعةواسعة منالتطبيقات。

بالانتقالإلىلوح=u0627ت الشاشة الخطافية، فهي مشهورةبسهولةالتركيب وتعددالاستخدامات。 تعملالخطافات الموجودةعلى===u0648افهذه اللوحات على تسهيل التث بيت السريعوالفصل عنإطارالشاشة الاهتزازية。 تعتبرهذهالميزةمفيدة بشكلخاصفيالصناعات التي تحتاج إلى تغيير الشاشات بشكلمتكرر لاستيعابأنواعمختلفة منالموادأوأحجام الجسيمات。 تساعد قابليةالتبادل السريععلىتقليلوقت التوقفعنالعملوزيادة