Manufacturer PU sieve Ore,outright sale shaker PU panel Dewatering

Maximizing Efficiency with pu panel Dewatering: How to Get the Most Out of Your Ore Processing Plant.

PU panel dewatering is a cost-effective and efficient way to maximize ore processing efficiency. This blog post will discuss the benefits of using PU panel dewatering, how it works, and how it can help you get the most out of your ore processing plant. We will also discuss the advantages of outright sale shaker PU panel dewatering and how it can help you save money in the long run

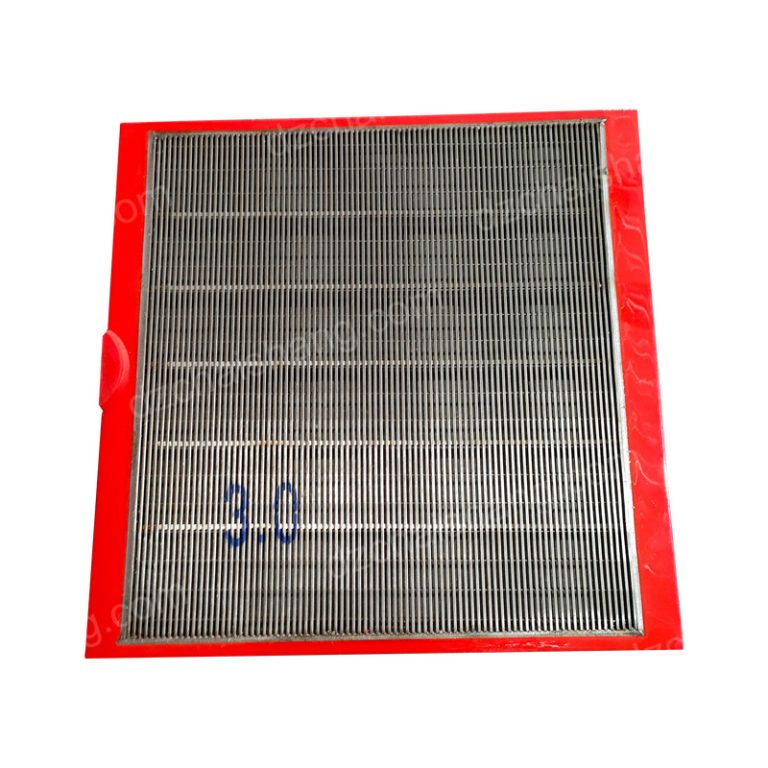

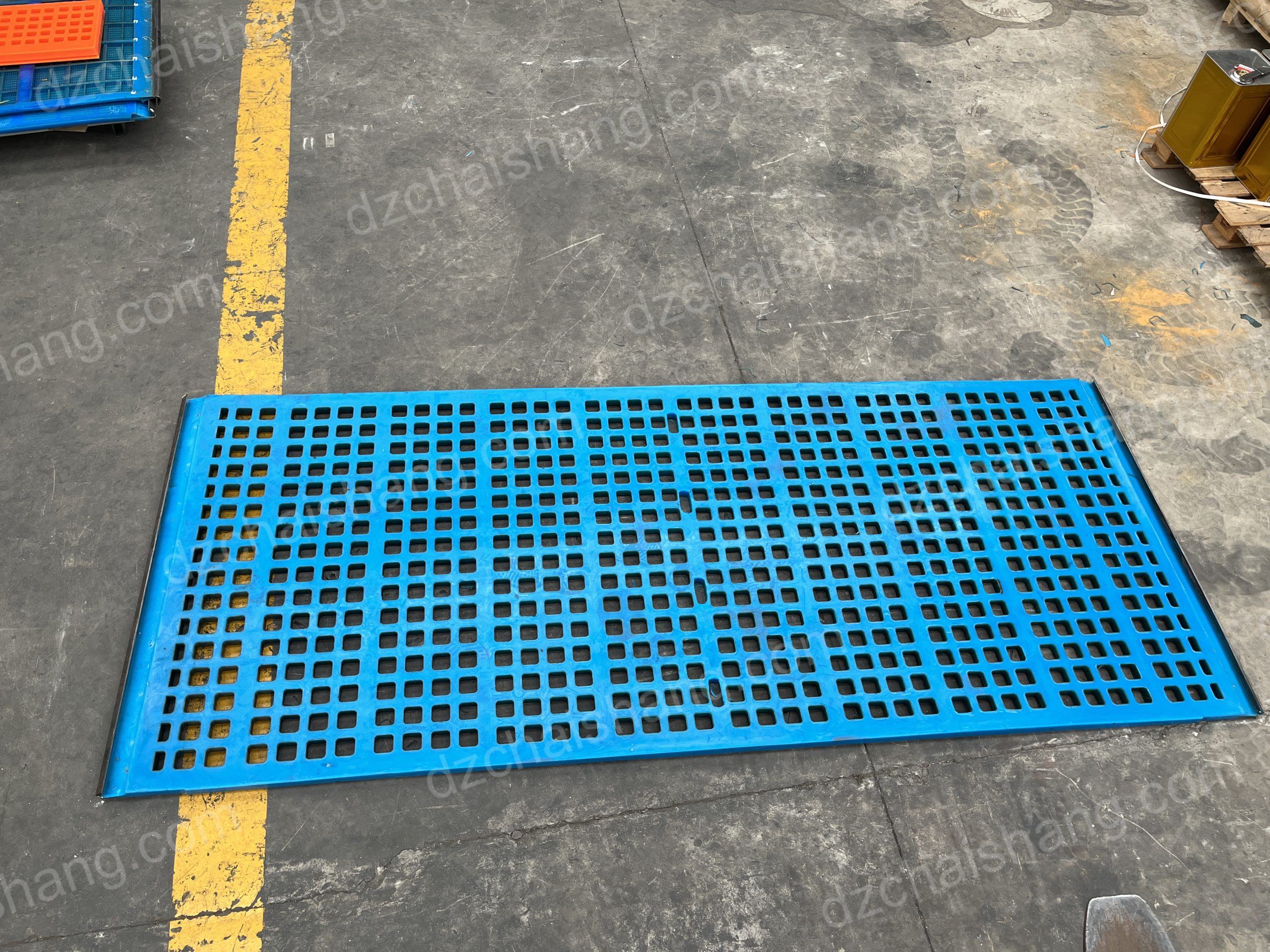

PU panel dewatering is a cost-effective and efficient way to maximize ore processing efficiency. This technology uses a series of panels to separate and dewater ore particles, allowing for a more efficient and cost-effective ore processing process. The panels are made of polyurethane, which is a durable and lightweight material that is resistant to corrosion and abrasion. This makes it ideal for use in ore processing plants.

The PU panel dewatering system works by separating ore particles into different sizes and then dewatering them. The panels are arranged in a stack, with the largest particles at the bottom and the smallest particles at the top. As the ore particles move through the stack, they are separated and dewatered. This process allows for a more efficient and cost-effective ore processing process.

Using PU panel dewatering can help you get the most out of your ore processing plant. This technology can help you reduce costs by reducing the amount of water needed for ore processing, as well as reducing the amount of energy needed to process the ore. Additionally, it can help you increase the efficiency of your ore processing plant by allowing for a more efficient and cost-effective ore processing process.

Outright sale shaker PU panel dewatering is another cost-effective and efficient way to maximize ore processing efficiency. This technology uses a series of panels to separate and dewater ore particles, allowing for a more efficient and cost-effective ore processing process. The panels are made of polyurethane, which is a durable and lightweight material that is resistant to corrosion and abrasion. This makes it ideal for use in ore processing plants.

Outright sale shaker PU panel dewatering can help you save money in the long run. This technology can help you reduce costs by reducing the amount of water needed for ore processing, as well as reducing the amount of energy needed to process the ore. Additionally, it can help you increase the efficiency of your ore processing plant by allowing for a more efficient and cost-effective ore processing process.

PU panel dewatering and outright sale shaker PU panel dewatering are both cost-effective and efficient ways to maximize ore processing efficiency. These technologies can help you reduce costs by reducing the amount of water needed for ore processing, as well as reducing the amount of energy needed to process the ore. Additionally, they can help you increase the efficiency of your ore processing plant by allowing for a more efficient and cost-effective ore processing process.