Polyurethane screen life and factors affecting polyurethane life.

Understanding the Importance of polyurethane screen Life

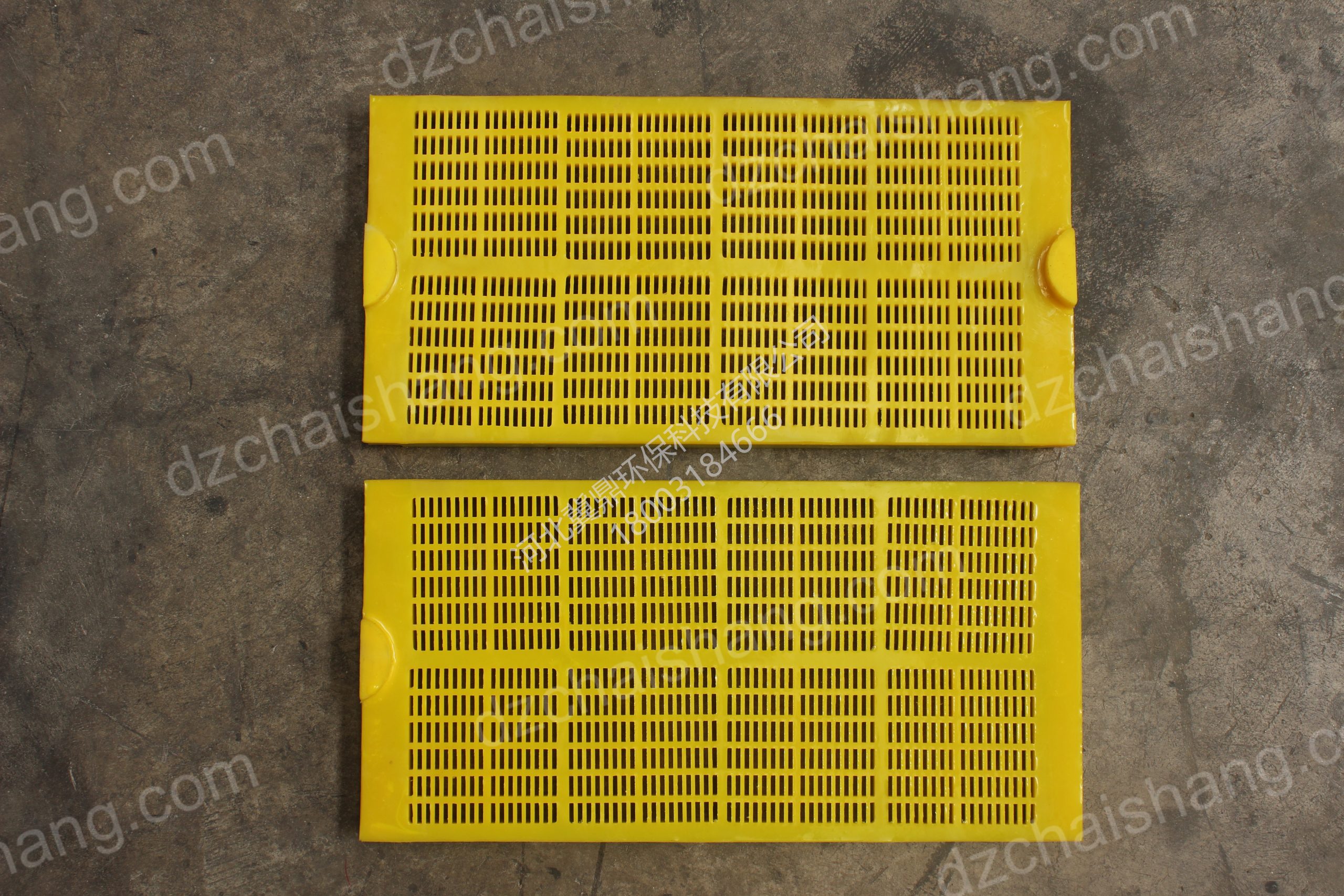

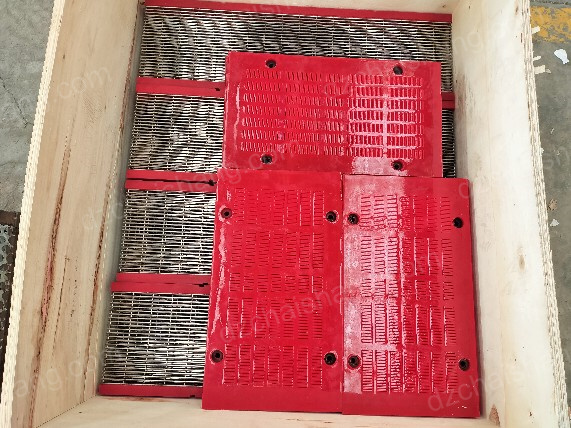

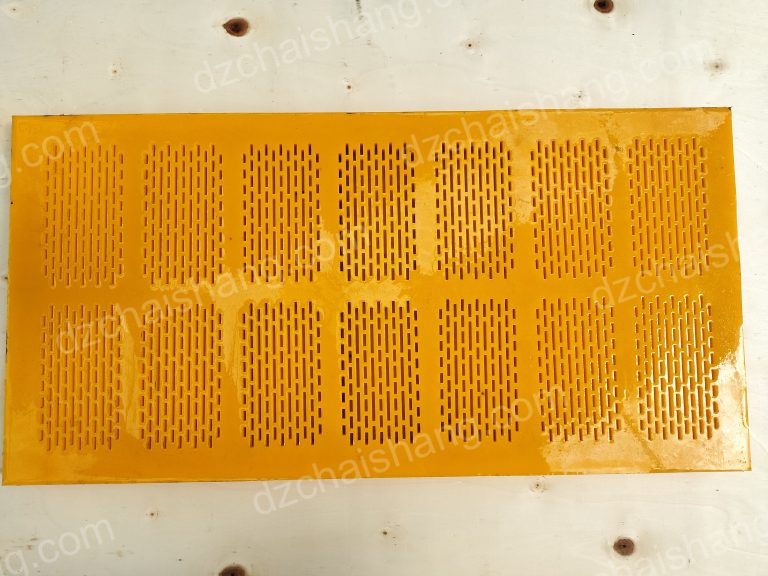

polyurethane screens are widely used in various industries, including mining, construction, and recycling. These screens play a crucial role in separating and classifying materials, ensuring efficient operations and high-quality end products. However, like any other equipment, polyurethane screens have a limited lifespan. Understanding the factors that affect polyurethane screen life is essential for maximizing their efficiency and longevity.

One of the primary factors that influence polyurethane screen life is the material being processed. Different materials have varying levels of abrasiveness, which can significantly impact the wear and tear on the screen. For example, materials like sand and gravel are highly abrasive and can cause rapid deterioration of the screen surface. On the other hand, softer materials like coal or limestone are less abrasive and may result in a longer screen life.

Another crucial factor affecting polyurethane screen life is the frequency and intensity of use. Screens that are subjected to continuous and heavy-duty operations are more likely to wear out quickly compared to screens used intermittently or for lighter applications. The constant impact and friction from the materials passing through the screen can gradually degrade the polyurethane surface, reducing its effectiveness over time.

Maintenance practices also play a significant role in determining the lifespan of polyurethane screens. Regular cleaning and inspection are essential to remove any buildup of material or debris that can cause blockages or damage to the screen. Additionally, proper lubrication of the screen components, such as the bearings and tensioning system, can help reduce friction and extend the screen’s life.

The design and construction of the polyurethane screen itself are critical factors in determining its longevity. Screens with thicker polyurethane layers generally have a longer lifespan compared to screens with thinner layers. The thickness of the polyurethane layer provides a greater buffer against abrasion and impact, protecting the underlying structure of the screen. Additionally, screens with reinforced edges or support bars are more resistant to wear and tear, as they distribute the stress and strain more evenly across the screen surface.

Environmental conditions can also affect the life of polyurethane screens. Extreme temperatures, excessive moisture, or exposure to chemicals can accelerate the degradation of the polyurethane material. It is crucial to consider these factors when selecting and installing polyurethane screens, ensuring they are suitable for the specific operating environment.

understanding the importance of polyurethane screen life is vital for optimizing the efficiency and productivity of various industries. Factors such as the material being processed, frequency of use, maintenance practices, design, and environmental conditions all contribute to the lifespan of polyurethane screens. By considering these factors and implementing appropriate measures, such as regular maintenance and selecting screens with suitable designs, businesses can maximize the longevity of their polyurethane screens, reducing downtime and improving overall operational efficiency.