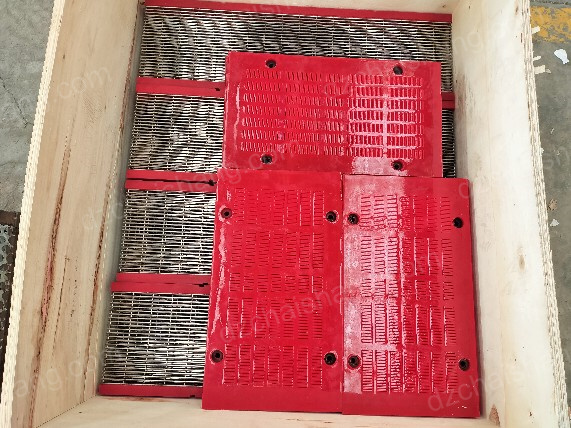

tấm màn hình polyurethane,sàng lọc polyurethane

أصبحت ألواح ==.. …” الصناعات。 وتشتهر الألوا= بمتانتهاوكفاءتا .. ممايجعلهاالخيار المفضلللعديدمن الشركات。 ” أوالمطاط。 واحدةمنأهممزايا ألواشاشة البولي يوريثينهيمتانث الاستث نائية。 فهي مقاومةللتآكل ” ” .. = ” الاستبدال。

ميزةأخ

في صناعة إعادة .. .. درً احاسمًافيفف موادالنفايات。 ويمكنهافصلالأنوة المختلفةمنالما القابلةلإعادة .. .. ‘ .. الألواح لتصنيفوفر أحجاممختلف ةمنالركام。 … عالي الجودة。

ف อี u064a شاشة البولي .. ..20 0b

บีلعملياتالغربلة。 تساهممتانتهاوكف) الفحصالعاليةوخ

في صناعة إعادة .. .. درً احاسمًافيفف موادالنفايات。 ويمكنهافصلالأنوة المختلفةمنالما القابلةلإعادة .. .. ‘ .. الألواح لتصنيفوفر أحجاممختلف ةمنالركام。 … عالي الجودة。

ف e u064a شاشة البولي .. ..20 0b

B bلعملياتالغربلة。 تساهممتانتهاوكف) الفحصالعاليةوخ