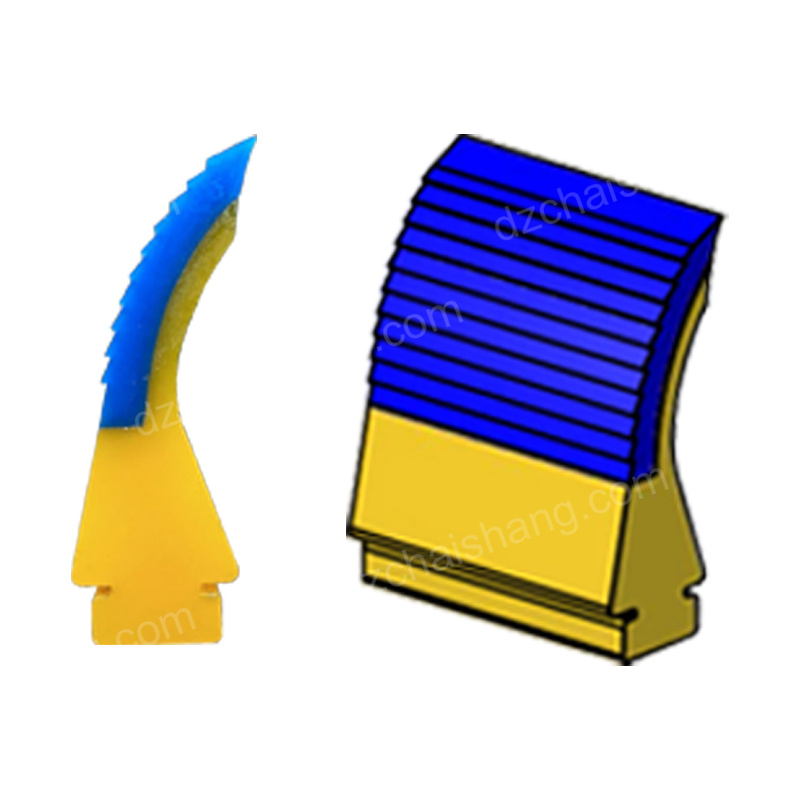

Dual hardness cleaner

Material: Polyurethane

Hardness: 80-95 Shore A

Size: Can be customized

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

- Satisfaction Guaranteed

- Accurate dimensions

- Guaranteed installation

Description

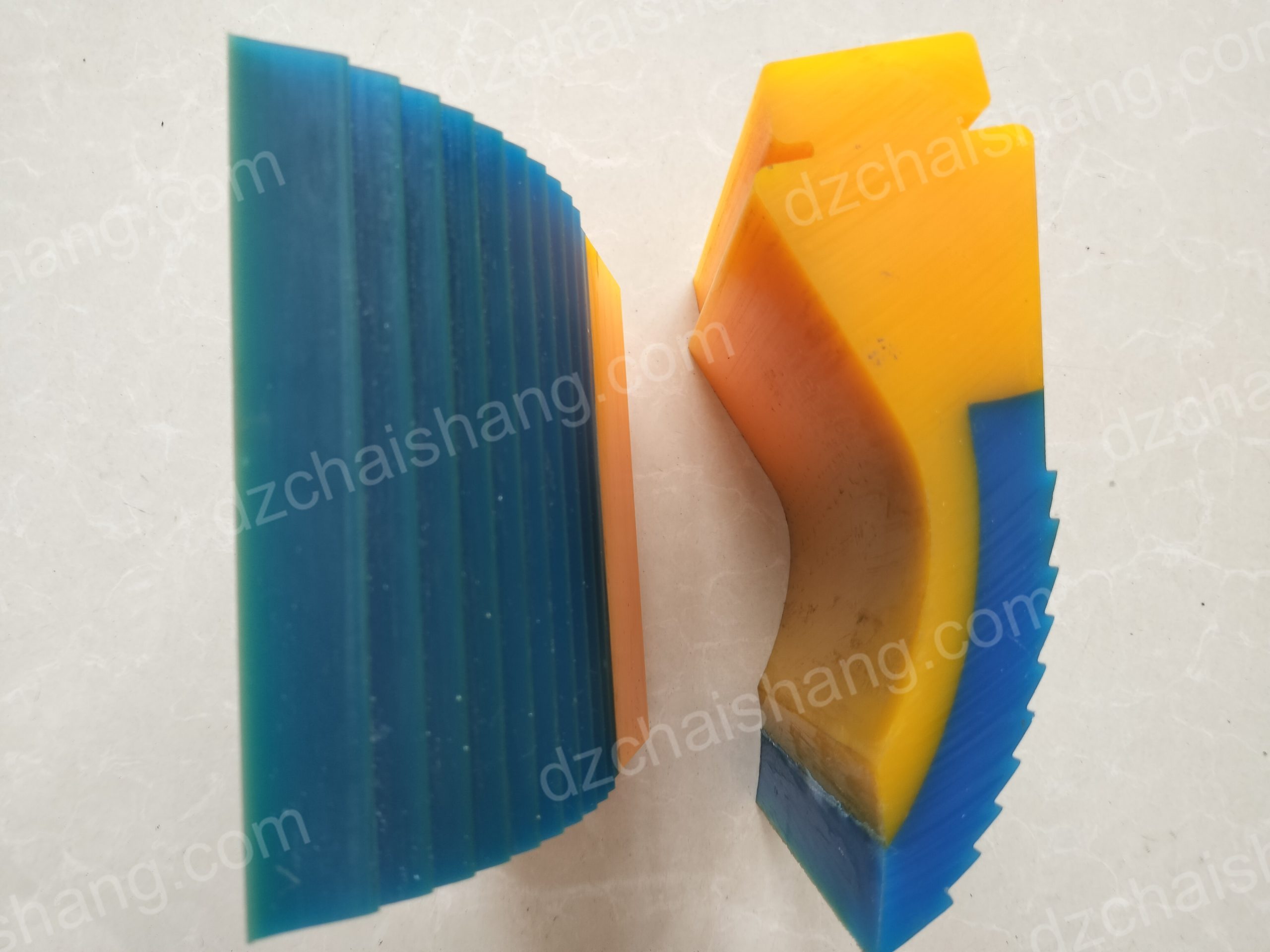

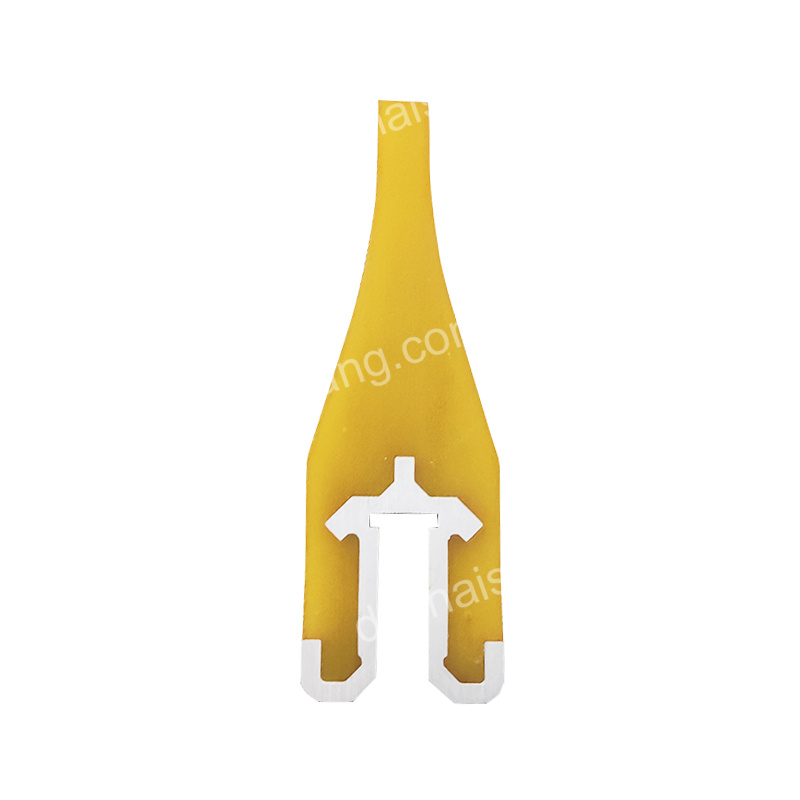

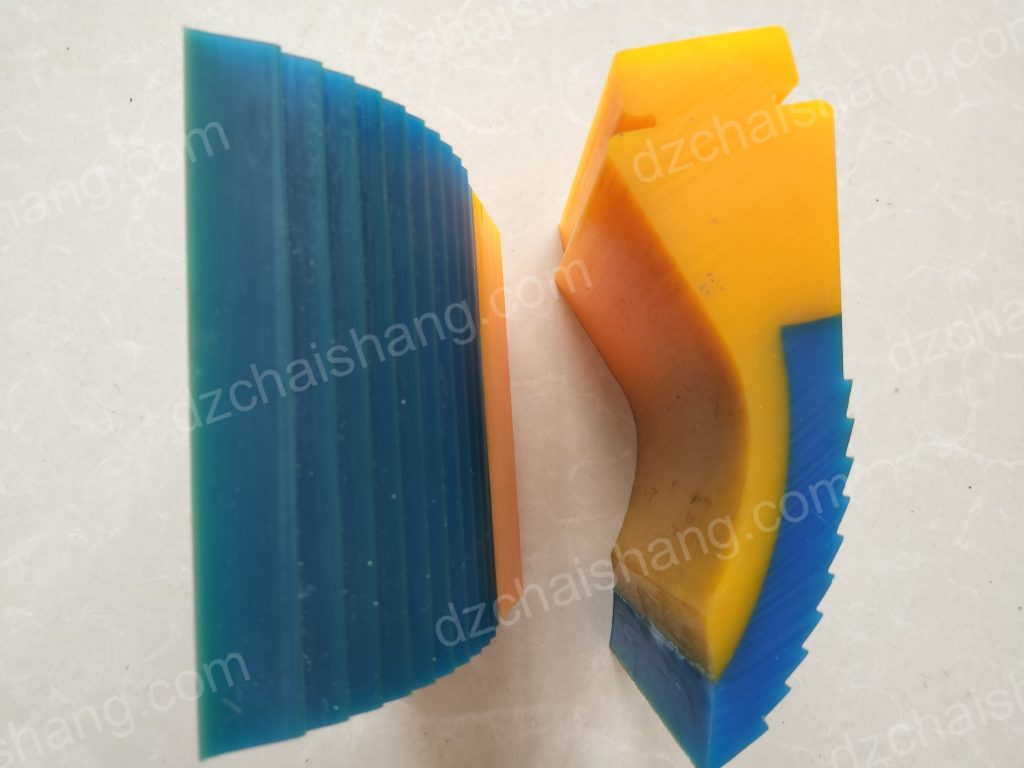

The polyurethane scraper has low friction, high wear resistance, and high strength. It has a stable scraping effect and can effectively remove fine particles and wet and sticky materials remaining on the belt. At the same time, the application fields of polyurethane scrapers are also very wide, such as in concrete mixing stations, cement coal mine sand fields, mineral smelting, etc.

When choosing a polyurethane scraper, I recommend that you choose a scraper with the following four characteristics:

1. Excellent cleaning efficiency. When adjusted to optimal tension, polyurethane scrapers provide excellent cleaning performance and are more belt-friendly than tungsten carbide scrapers.

2. High value. Polyurethane squeegees are often a more economical squeegee choice. Still, you should choose a scraper that provides you with good value, considering the lifetime cost and initial cost.

3. Compatibility. Polyurethane is highly compatible with the mechanical joints used on conveyor belts. If a mechanical splice is used on the conveyor belt, a polyurethane scraper would be ideal. The scraper does not damage joints while providing effective cleaning performance.

4. Versatility. There are many applications that require specialized formulations, such as resistance to high temperatures, resistance to chemicals, or removal of moisture. Be sure to choose the right polyurethane scraper for your application.

Application scenarios of polyurethane scrapers

Polyurethane scrapers are used in many different applications and industries. If you’re not sure if a polyurethane scraper is right for you, consider using a polyurethane scraper if:

Conveyor belts with mechanical joints. Conveyor belts with mechanical splices are an ideal application for polyurethane scrapers, which are fully compatible with mechanical splices. The polyurethane scraper glides easily over joints and sacrifices itself to protect joints when necessary, minimizing interruptions in cleaning. Note: Flexco Tungsten Carbide C-Blade Scrapers can be used on mechanically spliced conveyor belts, you can read more about that here.

Highly abrasive materials. When a conveyor belt production line transports abrasive materials, polyurethane scrapers are a good choice because they have a longer wear life.

First level conveyor belt cleaner. Polyurethane scrapers were originally used on primary cleaners – specifically on the head drum – where the belt needs to remain flat and can withstand few problems. For example, this primary cleaner or this primary cleaner are both ideal choices for primary cleaning.

Secondary conveyor belt cleaner. Polyurethane scrapers can be used effectively in secondary cleaner applications because they are particularly good at removing fines, increasing cleaning efficiency up to 90%. For example, this two-stage conveyor belt cleaner has excellent cleaning efficiency and can reduce maintenance time. This real-life example comes from a sand and gravel plant.