Lưới màn hình rung, bảng màn hình PU, lưới màn hình PU

فوائد استخدام شبكة الشاشة الاهتزازية في التطبيقات الصناعية

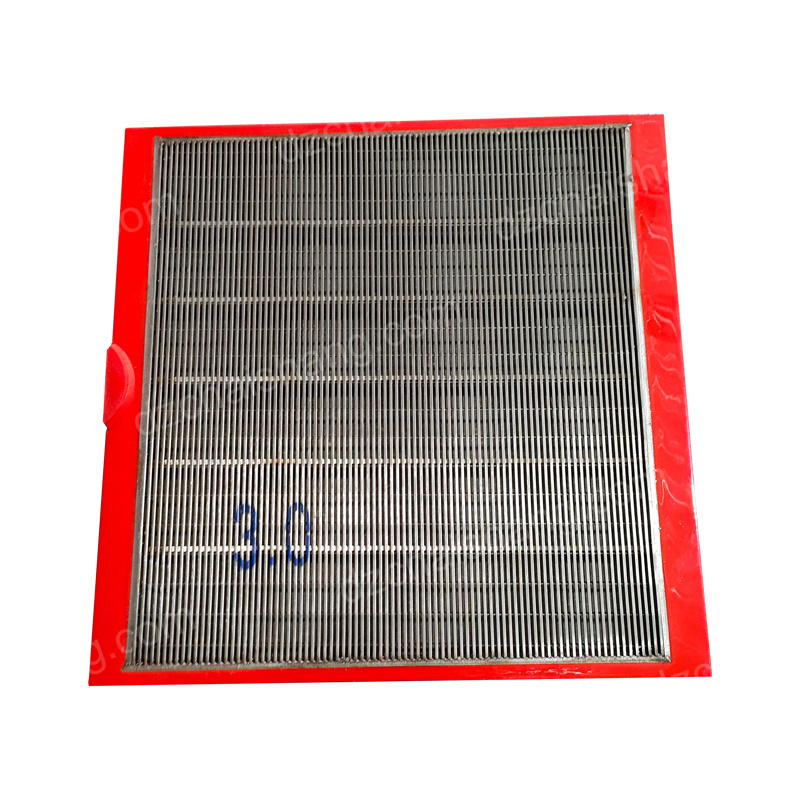

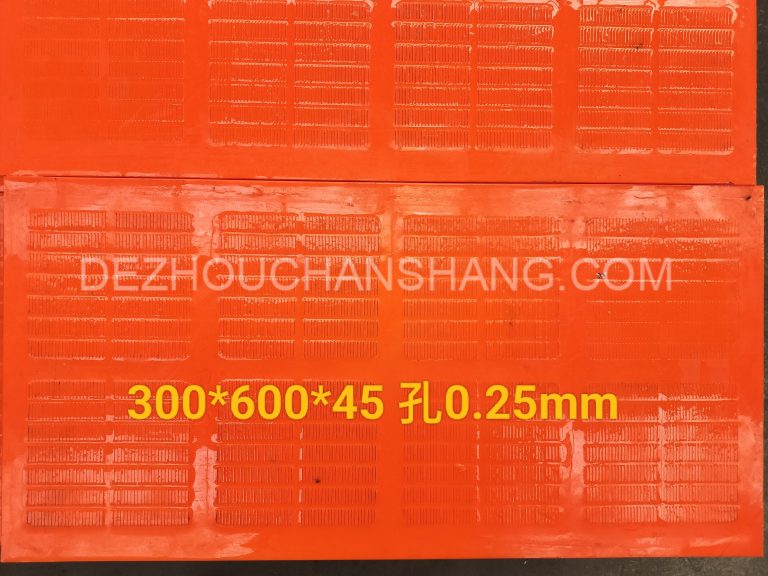

شبكة الشاشة الاهتزازية ، والمعروفة أيضًا باسم القماش الأسلاك ، هي عنصر متعدد الاستخدامات وأساسي في العديد من التطبيقات الصناعية. يتم استخدامه بشكل شائع في الصناعات مثل التعدين ، والتجميع ، وإعادة التدوير ، والبناء لفصل وتصنيف المواد على أساس الحجم. تتكون الشبكة من مواد عالية الجودة مثل الفولاذ المقاوم للصدأ أو البولي يوريثان أو المطاط ، مما يضمن المتانة وطول العمر في ظروف التشغيل القاسية.