shaker trommel Urethane panel Maker,shaker Polyurethane trommel screen ODM minerial

How Shaker Trommel urethane Panels are Revolutionizing the mining Industry

The mining industry is undergoing a revolution with the introduction of Shaker Trommel Urethane Panels. These panels are designed to provide a more efficient and cost-effective way to process ore.

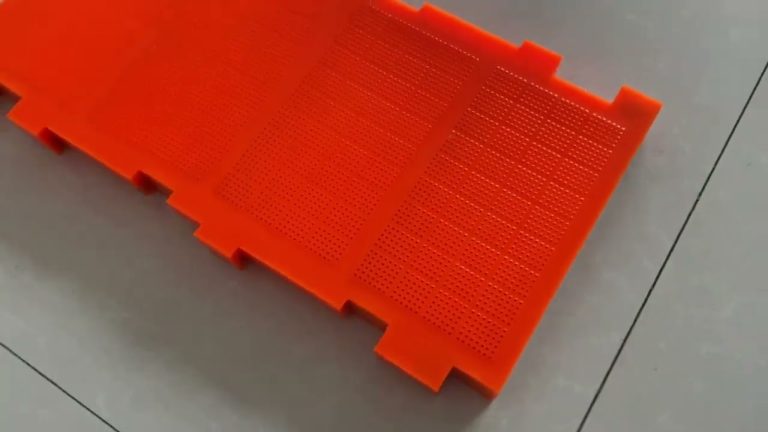

Shaker Trommel Urethane Panels are made from a durable, wear-resistant urethane material that is designed to withstand the harsh conditions of the mining environment. The panels are designed to be lightweight and easy to install, making them ideal for use in remote locations.

The panels are designed to be used in conjunction with a trommel, which is a rotating drum that is used to separate ore from waste material. The panels are designed to be placed on the trommel, allowing the ore to be separated from the waste material more efficiently. The panels also help to reduce the amount of dust and debris that is created during the mining process.

The panels are designed to be highly efficient, allowing for a higher throughput of ore. This increased efficiency leads to a reduction in the amount of time and energy required to process ore, resulting in cost savings for the mining company.

The panels are also designed to be easy to maintain, reducing the amount of downtime required for maintenance. This helps to reduce the amount of money that is spent on maintenance and repairs, resulting in further cost savings.

Shaker Trommel Urethane Panels are revolutionizing the mining industry by providing a more efficient and cost-effective way to process ore. The panels are designed to be lightweight and easy to install, allowing for a higher throughput of ore. They are also designed to be easy to maintain, reducing the amount of downtime required for maintenance. These features make Shaker Trommel Urethane Panels an ideal solution for the mining industry.

Exploring the Benefits of polyurethane Trommel screens for ODM Mineral Processing

Polyurethane trommel screens are becoming increasingly popular in the mineral processing industry due to their superior performance and cost-effectiveness. Polyurethane trommel screens offer a number of advantages over traditional steel trommel screens, including improved wear resistance, increased throughput, and reduced maintenance costs.

Polyurethane trommel screens are designed to provide superior wear resistance compared to traditional steel trommel screens. This is due to the fact that polyurethane is a much more durable material than steel, and is able to withstand the harsh conditions of mineral processing operations. Polyurethane trommel screens are also able to withstand higher levels of abrasion, which can lead to increased throughput and reduced maintenance costs.

In addition to improved wear resistance, polyurethane trommel screens also offer increased throughput. This is due to the fact that polyurethane is a much lighter material than steel, which allows for a larger open area on the screen. This larger open area allows for more material to pass through the screen, resulting in increased throughput.

Finally, polyurethane trommel screens offer reduced maintenance costs. This is due to the fact that polyurethane is much easier to clean and maintain than steel. Polyurethane trommel screens are also much less likely to corrode or rust, which can lead to costly repairs and replacements.

Overall, polyurethane trommel screens offer a number of advantages over traditional steel trommel screens for ODM mineral processing. These advantages include improved wear resistance, increased throughput, and reduced maintenance costs. As such, polyurethane trommel screens are becoming increasingly popular in the mineral processing industry.