Tấm sàng lưới màn hình Polyurethane, tấm lưới

إنألوا===u0627لغربال الشبكيةالمصنوعةF .. تتميزأيضًابخ

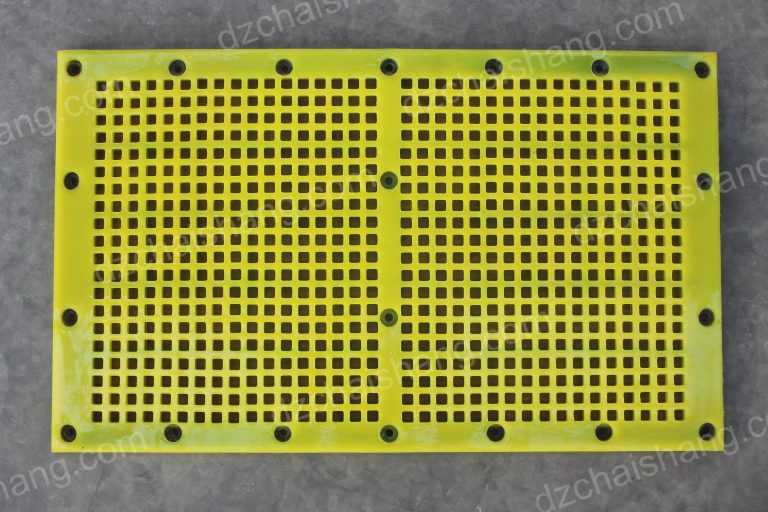

علاوةعلىذلك،فإن ألواحالغربالالشبكية المصنوعةمنمادة البولي يوريثينمقاومة للتآكل، مما يجعلها مناسبةللاستخدامفي البيئات القاسية والمسببةللتآكل。 تضمنهذهالمقاومة للتآكلأنتح=u0627فظألوا= الغربالعلىسلامتها وأدائهاحتىفيالظروف الصعبة، مما يؤدي إلى إطالةعمرهاالافتراضي وتقليلتكاليف الصيانة。

ميزةأخ

إنألوا===u0627لغربال الشبكيةالمصنوعةمن مادةالبولييوريثين تتميزأيضًابخ