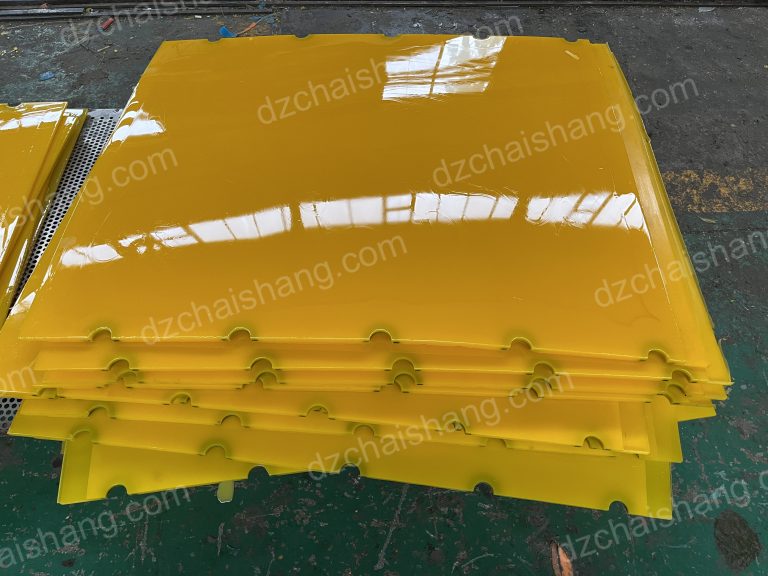

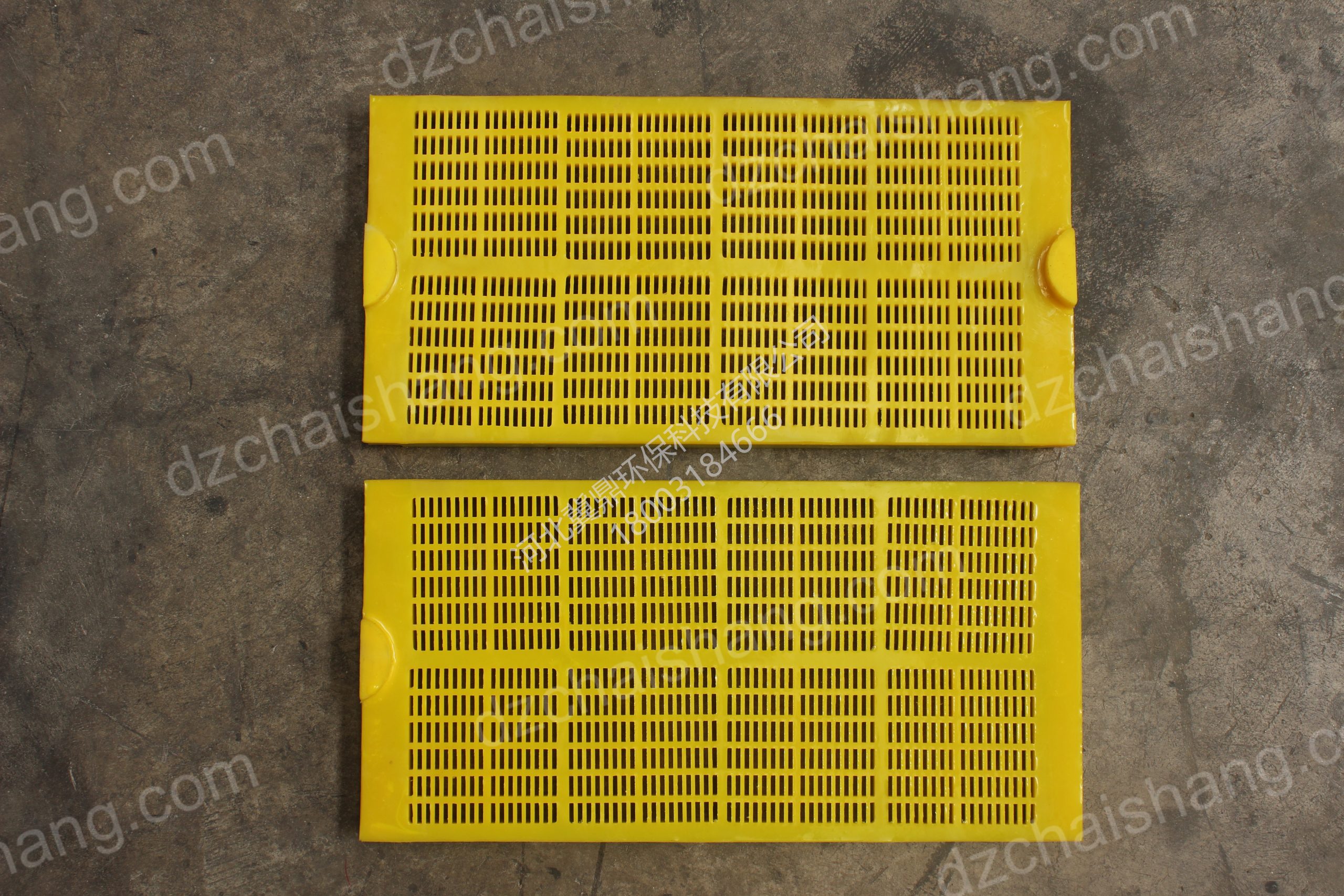

high frequency panel

The Benefits of Using high frequency Panels in Construction

High Frequency Panels, also known as HFPs, have become increasingly popular in the construction industry due to their numerous benefits. These panels are made from a combination of wood fibers and resins, which are compressed under high pressure and temperature to create a strong and durable material. In this article, we will explore the advantages of using high frequency panels in construction. One of the main benefits of high frequency panels is their exceptional strength. The manufacturing process ensures that the wood fibers are tightly bonded together, resulting in a panel that is resistant to warping, cracking, and splitting. This makes HFPs ideal for use in structural applications, such as walls, floors, and roofs. Their strength also allows for greater load-bearing capacity, making them suitable for heavy-duty construction projects. In addition to their strength, high frequency panels are also highly resistant to moisture and humidity. The resins used in their production act as a barrier, preventing water from seeping into the wood fibers. This makes HFPs ideal for use in areas with high humidity or where moisture exposure is a concern, such as bathrooms, kitchens, and basements. Their moisture resistance also helps to prevent the growth of mold and mildew, ensuring a healthier indoor environment.

In conclusion, high frequency panels offer numerous benefits in construction. Their exceptional strength, moisture resistance, versatility, and environmental friendliness make them a preferred choice for builders and architects. Additionally, their thermal and acoustic insulation properties contribute to improved comfort and energy efficiency. By incorporating high frequency panels into construction projects, builders can ensure durability, sustainability, and enhanced performance.

In conclusion, high frequency panels offer numerous benefits in construction. Their exceptional strength, moisture resistance, versatility, and environmental friendliness make them a preferred choice for builders and architects. Additionally, their thermal and acoustic insulation properties contribute to improved comfort and energy efficiency. By incorporating high frequency panels into construction projects, builders can ensure durability, sustainability, and enhanced performance.