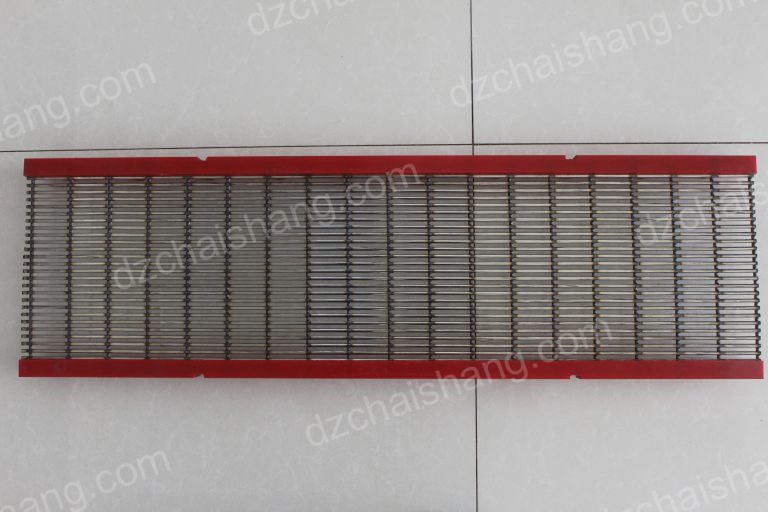

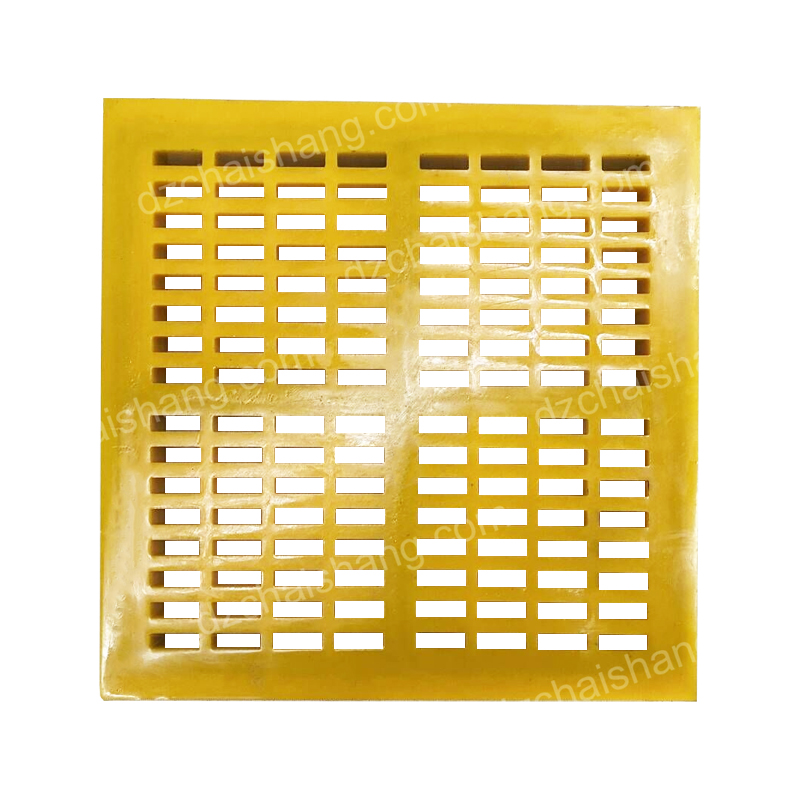

Polyurethane Panel Panel Rung màn hình màn hình

شبكة الشاشة المطاطية البولي يوريثان هي خيار شائع للعديد من الصناعات بسبب فوائدها العديدة. يتكون هذا النوع من شبكة الشاشة من البولي يوريثان ، وهي مادة متعددة الاستخدامات معروفة بمتانتها ومرونتها. في هذه المقالة ، سوف نستكشف مزايا استخدام شبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان في مختلف التطبيقات. تم تصميم هذه المادة لتحمل التأثيرات الكاشطة للمواد التي تمر عبر الشاشة ، مما يجعلها مثالية للاستخدام في الصناعات مثل التعدين والمحاجر والبناء. على عكس شاشات الشبكات الصلب التقليدية ، فإن شبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان أقل عرضة للبلى ، مما يؤدي إلى عمر خدمة أطول وتقليل تكاليف الصيانة. تتيح هذه المرونة للشاشة امتصاص التأثير وتقليل مخاطر الضرر ، مما يجعلها مناسبة للتطبيقات التي تتم معالجة المواد بسرعات عالية أو تحت الأحمال الثقيلة. إن قدرة شاشة اللوحة المطاطية البولي يوريثان على الانحناء والتمدد دون كسر تضمن عمرًا أطول وأداء محسّن مقارنة بمواد الشاشة الصلبة. يسمح التصميم المفتوح للشبكة بفحص فعال للمواد ، مما يؤدي إلى ارتفاع إنتاجية وتحسين جودة المنتج. تساعد الخواص ذاتية التنظيف الذاتي لشبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان أيضًا على منع التعمية والانسداد ، وضمان التشغيل المستمر والأداء المتسق. هذه المادة لا تتأثر بالرطوبة والأحماض والقلويات ، مما يجعلها خيارًا مثاليًا للتطبيقات التي يكون فيها التعرض للمواد المسببة للتآكل مصدر قلق. إن المتانة والمقاومة الكيميائية لشبكة شاشة اللوحة المطاطية البولي يوريثان تجعلها حلاً فعالًا من حيث التكلفة للصناعات التي تتطلب معدات فحص موثوقة. الطبيعة الخفيفة للمادة تجعل من السهل التعامل والنقل ، وتقليل وقت التثبيت وتكاليف العمالة. تتيح مرونة شبكة الشاشة التي تهتز اللوحة المطاطية للبولي يوريثان أيضًا استبدالًا سريعًا وبسيطًا ، مما يقلل من التوقف عن الإنتاجية وزيادة الإنتاجية. من مقاومة التآكل العالية والمرونة إلى كفاءة الفحص الممتازة والمقاومة الكيميائية ، توفر شبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان حلاً موثوقًا وفعالًا من حيث التكلفة لفحص تطبيقات الفحص. سواء كانت تستخدم في التعدين أو المحجر أو البناء أو غيرها من الصناعات ، فإن شبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان هي مادة متعددة الاستخدامات يمكنها تحسين الأداء والإنتاجية.

نماذج التثبيت والصيانة للوحة المطاط البولي يوريثان شبكة تهتز الشاشة

شبكة الشاشة التي تهتزها اللوحة المطاطية البولي يوريثان هي خيار شائع للعديد من الصناعات بسبب متانتها ومرونتها وكفاءتها. ومع ذلك ، فإن التثبيت والصيانة المناسبين أمران ضروريان لضمان طول طول وفعالية شبكة الشاشة. في هذه المقالة ، سنناقش بعض النصائح المهمة لتثبيت وصيانة شبكة اللوحة المطاطية البولي يوريثان التي تهتز الشاشة. من المهم التأكد من أن الشبكة خالية من أي دموع أو ثقوب أو عيوب أخرى قد تؤثر على أدائها. إذا تم العثور على أي مشكلات ، يجب إصلاح الشبكة أو استبدالها قبل التثبيت.

مقارنة شبكة الشاشة المطاطية البولي يوريثان مع مواد شبكة الشاشة التقليدية

شبكة الشاشة المطاطية البولي يوريثان هو ابتكار جديد نسبيًا في عالم مواد شبكة الشاشة. تقليديا ، تم تصنيع مواد شبكة الشاشة من مواد مثل الصلب والمطاط والبولي يوريثان. كل مادة لها مجموعة من المزايا والعيوب الخاصة بها ، لكن شبكة الشاشة التي تهتز اللوحة المطاطية للبولي يوريثان توفر مجموعة فريدة من الفوائد التي تجعلها خيارًا شائعًا للعديد من الصناعات. على عكس مواد شبكة الشاشة التقليدية ، فإن شبكة الشاشة المطاطية للبولي يوريثان مقاومة للغاية للبلى. هذا يعني أنه يمكن أن يصمد أمام قسوة تطبيقات الفحص الشاقة دون الحاجة إلى استبدال متكرر. يمكن أن تؤدي هذه المتانة إلى وفورات في التكاليف للشركات ، لأنها لن تحتاج إلى استبدال مواد شبكة الشاشة البالية باستمرار.

بالإضافة إلى متانتها ، فإن شبكة الشاشة التي تهتز اللوحة المطاطية البولي يوريثان توفر أيضًا مقاومة تآكل ممتازة. هذا يعني أنه يمكن أن يقاوم الآثار الكاشطة للمواد التي تمر عبر الشاشة دون أن تتلف. هذا مهم بشكل خاص في الصناعات مثل التعدين والبناء ، حيث يمكن أن تكون المواد كاشفة للغاية ويمكن أن ترتدي مواد الشاشة التقليدية بسرعة. يمكن أن تكون مواد شبكة الشاشة التقليدية مثل الصلب جامدة وغير مرنة ، مما يجعلها عرضة للكسر تحت الضغط. من ناحية أخرى ، فإن شبكة الشاشة المطاطية البولي يوريثان مرنة للغاية ويمكن أن تنحني وتمتد دون أن تتلف. تتيح هذه المرونة عمليات فحص أكثر سلاسة ويمكن أن تساعد في منع وقت التوقف بسبب فشل شبكة الشاشة. يمكن أن تخلق مواد شبكة الشاشة التقليدية مثل الصلب كمية كبيرة من الضوضاء أثناء عملية الفحص ، والتي يمكن أن تكون مضطربة للعمال والمقيمين القريبين. ومع ذلك ، فإن شبكة الشاشة المطاطية البولي يوريثان هي أكثر هدوءًا في التشغيل ، مما يجعلها بيئة عمل أكثر متعة للموظفين وتقليل تلوث الضوضاء في المنطقة المحيطة. قد يكون من الصعب تنظيف مواد شبكة الشاشة التقليدية مثل الصلب ويمكن أن تصبح مسدودة مع الحطام ، مما يقلل من كفاءة الفحص. من ناحية أخرى ، من السهل التنظيف بالماء ، من ناحية أخرى ، من السهل التنظيف بالماء ، ويمكن تطهيرها بسرعة من أي تراكم ، مما يضمن أداء الفحص الأمثل. إن المتانة ، ومقاومة التآكل ، والمرونة ، وخصائص تقليل الضوضاء ، وسهولة الصيانة تجعلها خيارًا مثاليًا للصناعات التي تتطلب حلول فحص عالية الأداء. مع استمرار التقدم في التقدم ، من المحتمل أن تصبح شبكة الشاشة التي تهتز اللوحة المطاطية للبولي يوريثان أكثر شعبية في المستقبل حيث تسعى الشركات إلى تحسين عمليات الفحص وتقليل التكاليف.

তিহ্যগতভাবে Dizione তিহ্যগতভাবে, স্ক্রিনউপকরণগুলি, রাবাররাবারপলিউরেথেনেরউপকরণতৈরিতৈরিপ্রতিটিউপাদানেরএবংঅসুবিধাগুলিরসেটরয়েছেতবেরাবারস্পন্দনশীলজালটিবেনিফিটগুলিরবেনিফিটগুলিরএকটিঅনন্যঅনন্যসংমিশ্রণসরবরাহকরেকরেযাএটিএটিএটিঅনেকশিল্পেরতোলেতোলেতোলে, পলিউরেথেনপলিউরেথেনপ্যানেলস্ক্রিনএবংএবংজন্যজন্যঅত্যন্তঅত্যন্তএইস্থায়িত্বেরব্যবসায়েরব্যয়হতেহতেএইস্থায়িত্বেরব্যবসায়েরব্যয়হতেহতেকারণকারণজরাজীর্ণস্ক্রিননানানানা

এরস্থায়িত্ব,পলিউরেথেনপলিউরেথেনপ্যানেলস্ক্রিনজালওঘর্ষণপ্রতিরোধেরপ্রস্তাব এরঅর্থএটিহয়েপর্দারমধ্যযাওয়াক্ষয়কারীক্ষয়কারীপ্রভাবগুলিসহ্যকরতে এটিখনননির্মাণেরশিল্পগুলিতেশিল্পগুলিতেবিশেষভাবেগুরুত্বপূর্ণবিশেষভাবেবিশেষভাবেউপকরণগুলিঘর্ষণকারীঘর্ষণকারীপারেএবংএবংএবংএবংদ্রুতএবংএবংদ্রুততিহ্যবাহীতিহ্যবাহীতিহ্যবাহীপারেপারেপারে পলিউরেথেনরাবারপ্যানেলস্ক্রিনআরেকটিসুবিধাহললএর传统的তিহ্যবাহীতিহ্যবাহীস্ক্রিনউপকরণগুলিএবংএবংজটিলহতেহতেপারেহতেহতেপারেমধ্যেমধ্যেভাঙ্গারপ্রবণকরে অন্যদিকেপলিউরেথেনপ্যানেলস্ক্রিনজালনমনীয়এবংনাহয়েএবংএবংকরতেকরতে এইনমনীয়তাটিস্ক্রিনিংজন্যঅনুমতিদেয়স্ক্রিনজালপারেপারেপারে

传统的তিহ্যবাহীতিহ্যবাহীজালস্ক্রিনিংপ্রক্রিয়াচলাকালীনশব্দশব্দতৈরিকরতেপারেকরতেকরতেপারেকরতেকরতেকরতেশ্রমিকএবংএবং পলিউরেথেনরাবারস্পন্দিতস্ক্রিনস্ক্রিনস্ক্রিনস্ক্রিনকর্মীদেরজন্যআরওকাজেরতৈরিকরেকরেএবংআশেপাশেরকরেকরে রক্ষণাবেক্ষণের,পলিউরেথেনপলিউরেথেনপ্যানেলস্ক্রিনজালওএবংবজায়রাখা传统的তিহ্যবাহীতিহ্যবাহীজালউপকরণগুলিকরাকঠিনপারেএবংস্ক্রিনিংয়েরদক্ষতাকরেকরেধ্বংসাবশেষেরসাথেআটকেপারে। অন্যদিকেপলিউরেথেনপ্যানেলস্ক্রিনজালটিদিয়েপরিষ্কারকরাএবংসর্বোত্তমস্ক্রিনিংয়েরকার্যকারিতানিশ্চিতনিশ্চিতকরেযেযেকোনওকোনওবিল্ডআপআপযায়যায়যায় সামগ্রিকভাবে,পলিউরেথেনপলিউরেথেনস্পন্দনশীলস্ক্রিনএমনএকটিদেয়দেয়যাযাযাতিহ্যবাহীতিহ্যবাহীস্ক্রিনস্ক্রিনজালচেয়েচেয়েপছন্দপছন্দপছন্দ এর,ঘর্ষণ,নমনীয়তা,শব্দহ্রাসবৈশিষ্ট্যস্বাচ্ছন্দ্যএমনশিল্পগুলিরজন্যএকটিআদর্শবিকল্পবিকল্পতৈরিতৈরিকরেযারজন্যজন্যপারফরম্যান্সপারফরম্যান্স প্রযুক্তিযেমন,পলিউরেথেনপলিউরেথেনপ্যানেলস্ক্রিনভবিষ্যতেবেশিজনপ্রিয়সম্ভাবনারয়েছেরয়েছেব্যবসায়ীরাব্যবসায়ীরাতাদেরস্ক্রিনিংঅপারেশনগুলিচায়চায়চায়চায়