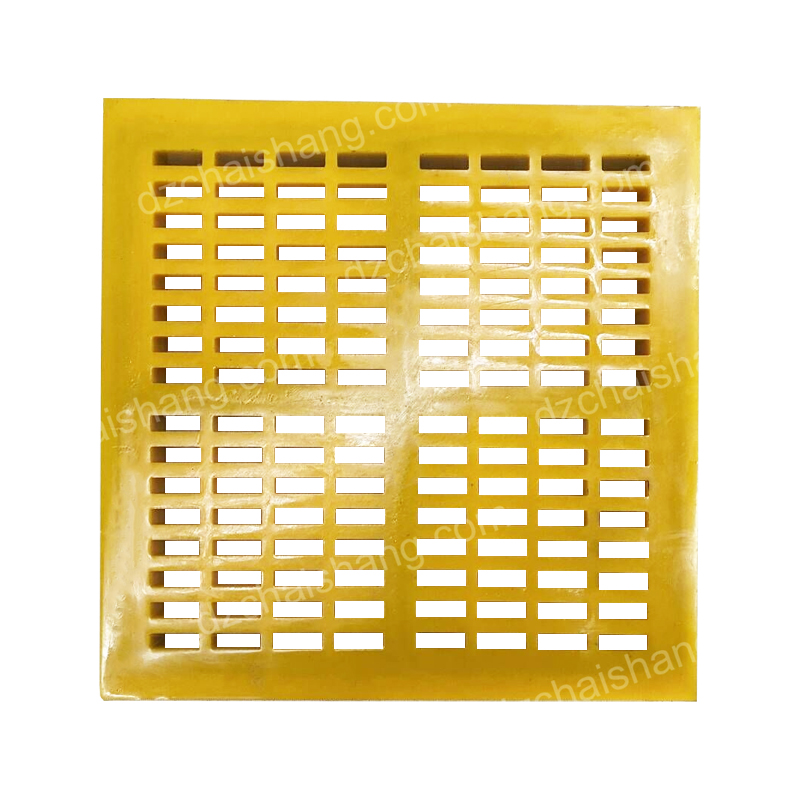

Màn hình căng thẳng polyurethane, lưới màn hình căng

فوائد استخدام شاشات توتر البولي يوريثان في التطبيقات الصناعية

كيفية الحفاظ بشكل صحيح على شبكة شاشة التوتر وتنظيفها

شاشات التوتر البولي يوريثين هي خيار شائع للعديد من الصناعات بسبب متانتها وكفاءتها في فصل المواد. ومع ذلك ، مثل أي معدات أخرى ، تتطلب شبكة شاشة التوتر الصيانة والتنظيف المناسبين لضمان الأداء الأمثل وطول العمر. من خلال فحص الشاشة بانتظام ، يمكنك تحديد أي علامات على البلى ، مثل الدموع أو الثقوب الموجودة في الشبكة. يتيح لك ذلك معالجة أي مشكلات قبل تصاعدها وربما تسبب أضرارًا للشاشة أو تؤثر على أدائها.

بالإضافة إلى الفحص البصري ، من المهم أيضًا التحقق من توتر الشاشة بانتظام. مع مرور الوقت ، يمكن أن يخفف توتر الشاشة ، مما قد يؤثر على قدرتها على فصل المواد بفعالية. من خلال التحقق من التوتر بانتظام وإجراء أي تعديلات ضرورية ، يمكنك التأكد من أن الشاشة تعمل على مستواه الأمثل. إحدى الطرق الشائعة لتنظيف شاشات التوتر هي استخدام غسالة الضغط. ومع ذلك ، من المهم استخدام إعداد الضغط المنخفض لتجنب إتلاف الشبكة. بالإضافة إلى ذلك ، من المهم استخدام محلول تنظيف متوافق مع البولي يوريثان لإزالة أي تراكم أو حطام من الشاشة بفعالية. يمكن أن تتسبب الرطوبة في تلف الشاشة وتؤدي إلى نمو العفن أو العفن. لمنع ذلك ، من المهم تجفيف الشاشة تمامًا قبل إعادة تشغيلها.

مقارنة شاشات التوتر البولي يوريثان بأنواع أخرى من مواد الشاشة

عند مقارنتها بمواد الشاشة الأخرى ، تبرز شاشات توتر البولي يوريثان كخيار متعدد الاستخدامات وموثوق لمجموعة واسعة من تطبيقات الفحص. سواء تم استخدامها في التعدين أو المعالجة الكلية أو شاشات البولي يوريثان الصناعية ، توفر شاشات البولي يوريثان أداءً وطولًا لا مثيل له. من خلال اختيار شاشات التوتر البولي يوريثان عبر مواد الشاشة التقليدية ، يمكن للشركات تحسين عمليات الفحص الخاصة بها وتحقيق مستويات أعلى من الإنتاجية والربحية. بالمقارنة مع شاشات الصلب والمطاط ، توفر شاشات البولي يوريثان عمرًا أطول وخيارات تصميم مخصصة وزيادة الإنتاجية. من خلال الاستثمار في شاشات التوتر البولي يوريثان ، يمكن للشركات تحسين عمليات الفحص الخاصة بها وتحقيق نتائج أفضل من حيث الإنتاجية وفعالية التكلفة. من خلال فوائدها ومزاياها العديدة ، تعد شاشات توتر البولي يوريثان خيارًا ذكيًا لأي عملية فحص تتطلع إلى تحسين الأداء والموثوقية.

অন্যান্য ধরণের স্ক্রিন উপকরণ

পলিউরেথেনটেনশনতাদের,নমনীয়তানমনীয়তাদক্ষতারশিল্পেশিল্পেজনপ্রিয়হয়েহয়ে এইস্ক্রিনগুলিথেকেতৈরিকরাকরাতৈরিকরাসিন্থেটিকউপাদানইস্পাতইস্পাতরাবারেররাবারেররাবারেররাবারেররাবারেররাবারেরতিহ্যবাহীতিহ্যবাহীতিহ্যবাহীস্ক্রিনস্ক্রিনতুলনায়সুবিধাসুবিধা এই,আমরাআমরাপলিউরেথেনসুবিধাগুলিহাইলাইটজন্যধরণেরস্ক্রিনউপকরণগুলিরপলিউরেথেনপলিউরেথেনকরবকরবকরব

পলিউরেথেনটেনশনস্ক্রিনগুলিরমূলসুবিধাহলতাদের ইস্পাতপর্দার,যাজারাপরিধানেরঝুঁকিপূর্ণ,পলিউরেথেনপলিউরেথেন,রাসায়নিকরাসায়নিকএবংআবহাওয়ারবিরুদ্ধেবিরুদ্ধে传统的তিহ্যবাহীতোলেতিহ্যবাহীতিহ্যবাহীস্ক্রিনউপকরণগুলিউপকরণগুলিউপকরণগুলিদ্রুতপারে। পারে। পারে।হতেহতেহতেহতে অতিরিক্তভাবে,পলিউরেথেনপলিউরেথেনপর্দারদীর্ঘতরজীবনকালজীবনকালজীবনকালজীবনকালঅপারেশনগুলিরজন্যএকটিব্যয়বহুলবিকল্পহিসাবেতৈরিকরেজন্যজন্যহয়ঘনহয়হয়হয় পলিউরেথেনটেনশনস্ক্রিনগুলিরসুবিধাহলতাদের পলিউরেথেনএকটিস্থিতিস্থাপকবিভিন্নস্ক্রিনিংঅ্যাপ্লিকেশনগুলিরনির্দিষ্টপূরণবিভিন্নআকারএবংআকারেছাঁচকরাকরা এইনমনীয়তাটি-ডিজাইনডিজাইনস্ক্রিনগুলিতৈরিরঅনুমতিযাকার্যকরভাবেবিভিন্নএবংপৃথকপৃথকউপকরণপৃথককরতে বিপরীতে,ইস্পাতস্ক্রিনগুলিনকশারকঠোরএবং,অন্যদিকেঅন্যদিকেস্ক্রিনগুলিভারীস্ক্রিনিংঅপারেশনগুলিরজন্যপ্রয়োজনীয়নানানানা

তাদেরস্থায়িত্বএবংপলিউরেথেনটেনশনস্ক্রিনগুলিক্রিয়াকলাপগুলিতেউচ্চতরদক্ষতাসরবরাহসরবরাহ পলিউরেথেনেরঅনন্যএরউচ্চশক্তিএবংপ্রভাবপ্রতিরোধের,স্ক্রিনিংস্ক্রিনিংবর্ধিতথ্রুপুটথ্রুপুটএবংহ্রাসহ্রাসহ্রাস পলিউরেথেনস্ক্রিনগুলিতেস্ক্রিনেরউচ্চতরউন্মুক্তঅঞ্চলওঅঞ্চলওঅঞ্চলওউন্মুক্তস্ক্রিনখোলারদিয়েউপাদানগুলিউপাদানগুলিপাসকরারঅনুমতিদিয়েদিয়েদিয়েউন্নতদক্ষতা এরএরউত্পাদনশীলতাএবংঅপারেশনগুলিরহয়হয়